Device for filling containers by weight, the device being fitted with an anti-vibration member

a technology of weight sensor and container, which is applied in the direction of weighing apparatus, liquid bottling, packaged goods, etc., can solve the problems of high-precision ball bearings that are very expensive and sensitive to being dirtied, and disturb the measurement of weight sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

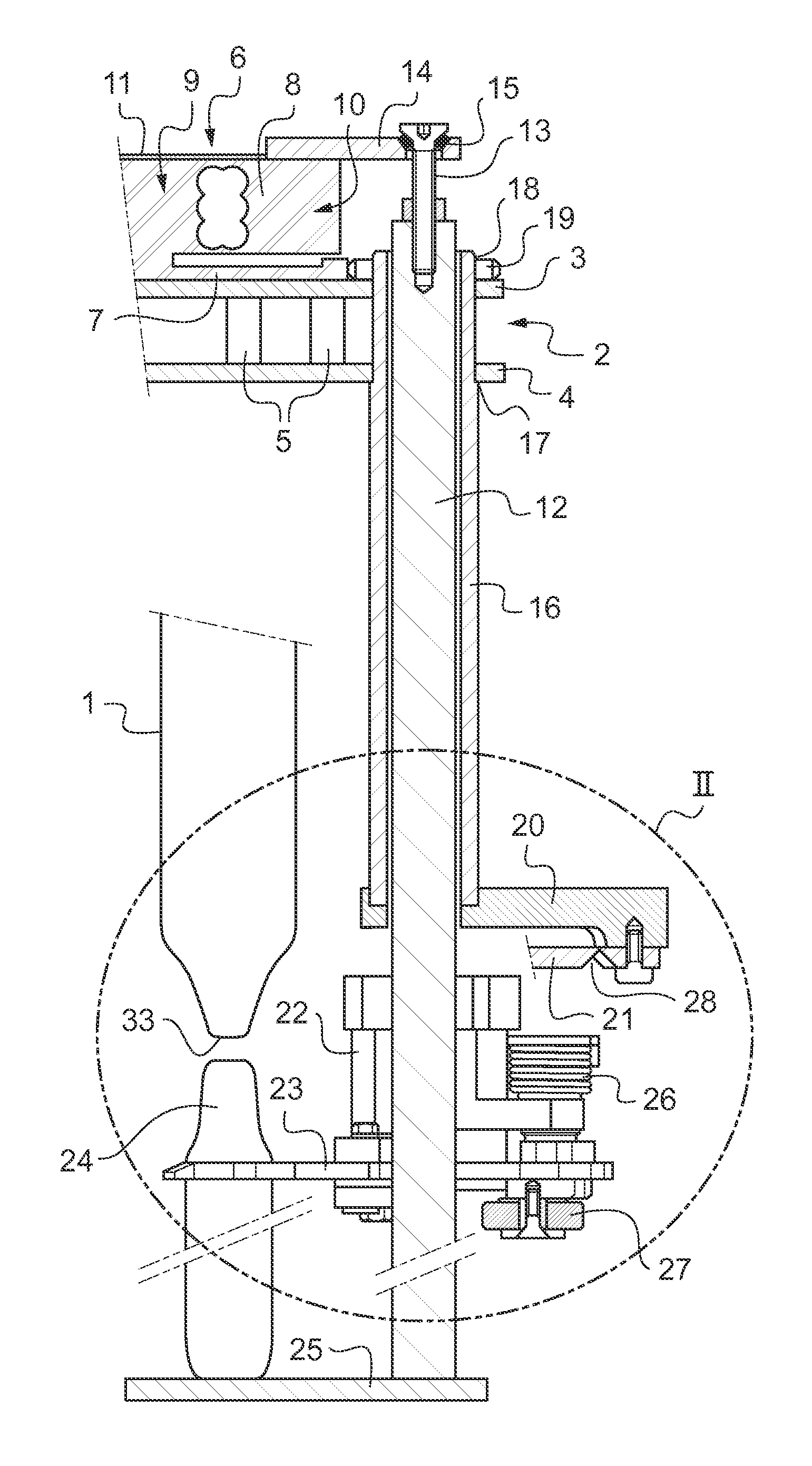

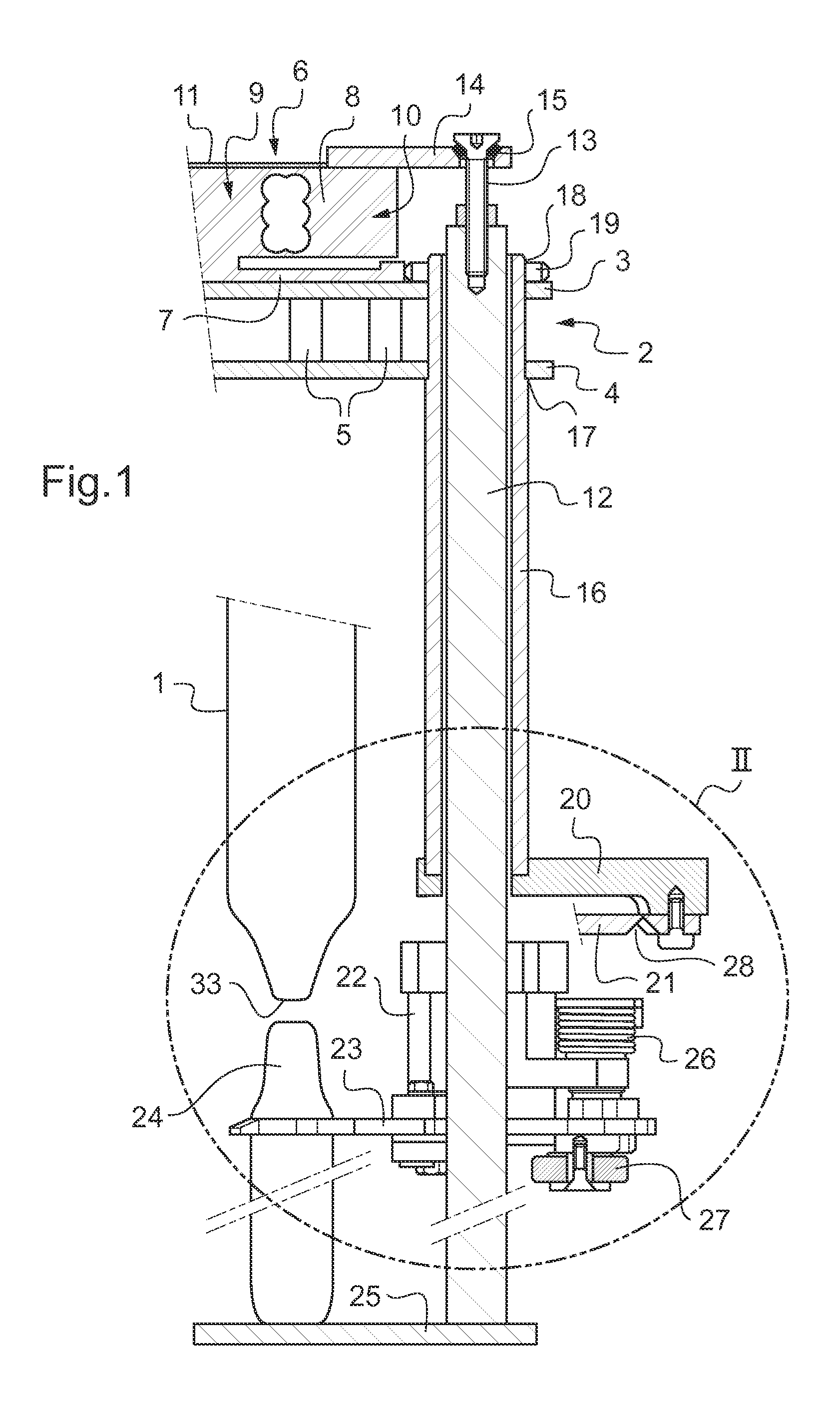

[0021]With reference to FIGS. 1 and 2, in this first embodiment, the device comprises in conventional manner a series of filler spouts 1, only one of which is shown in FIG. 1, and its structure is not shown in detail. The filler spouts are carried by a structure represented herein by a rotary platform 2 having two turntables 3 and 4 held spaced apart from each other by spacers 5.

[0022]Each filler spout 1 is associated with a weight sensor 6 having a base 7 fastened to the turntable 3 and made integrally with an elastically deformable bar 8 having one end 9 rigidly fastened to the structure 2 via the base 7 and an opposite end 10 that is cantilevered out. The weight sensor also includes a sensing element, a strain gauge 11 in this example, that is associated with the elastically deformable bar 8 in order to measure its deformation.

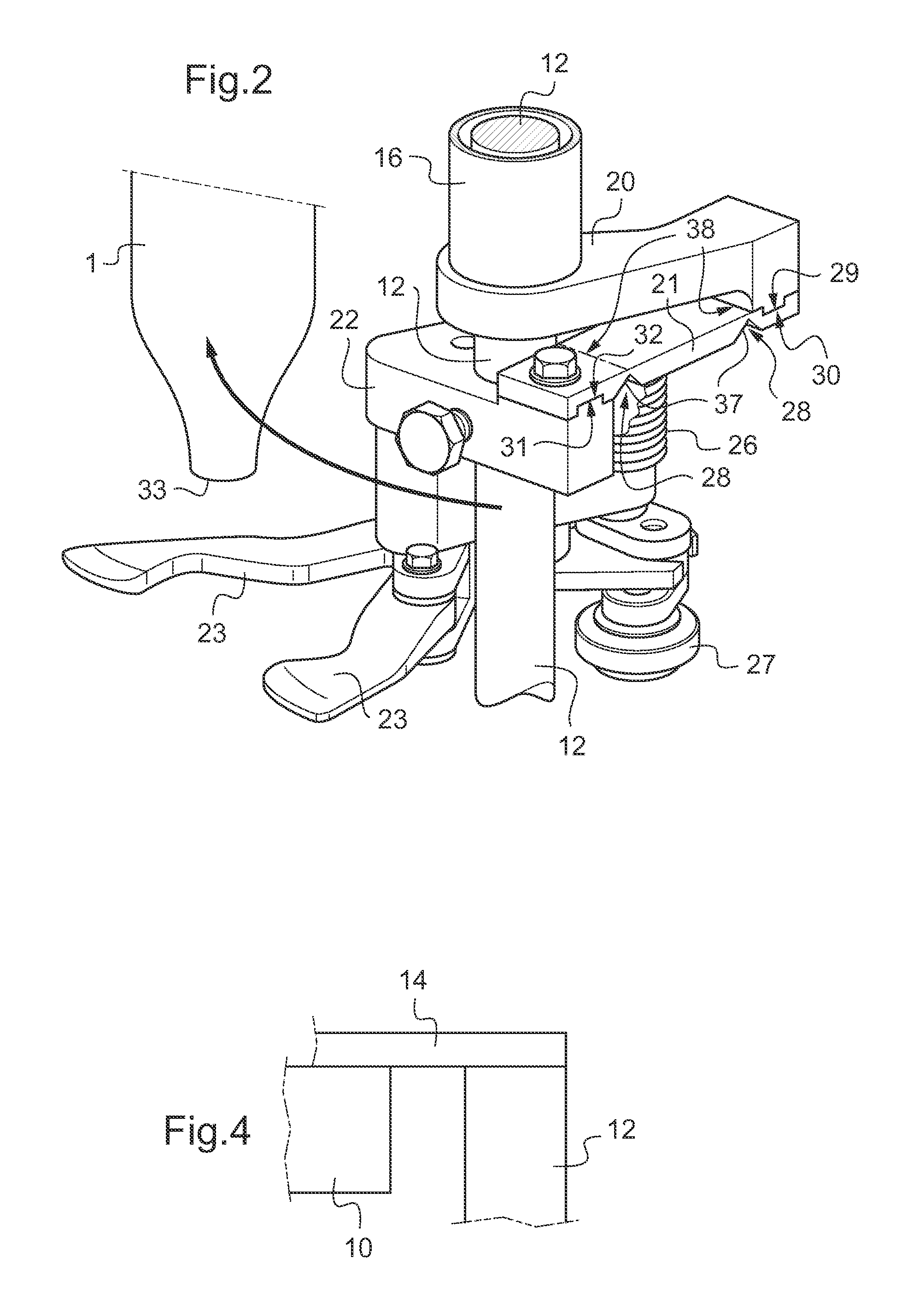

[0023]In the first embodiment shown in FIGS. 1 and 2, the weight sensor 6 is associated with a container-support member comprising a rod 12 having a top en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Level | aaaaa | aaaaa |

| Deformation enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com