Water retention/detention structure formed from identical panels

a technology of water retention and detention structure, which is applied in the direction of sewage draining, sewer system, construction, etc., can solve the problems of destroying habitat, contributing to storm sewer overflow, and inability to manage storm runoff water flow,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

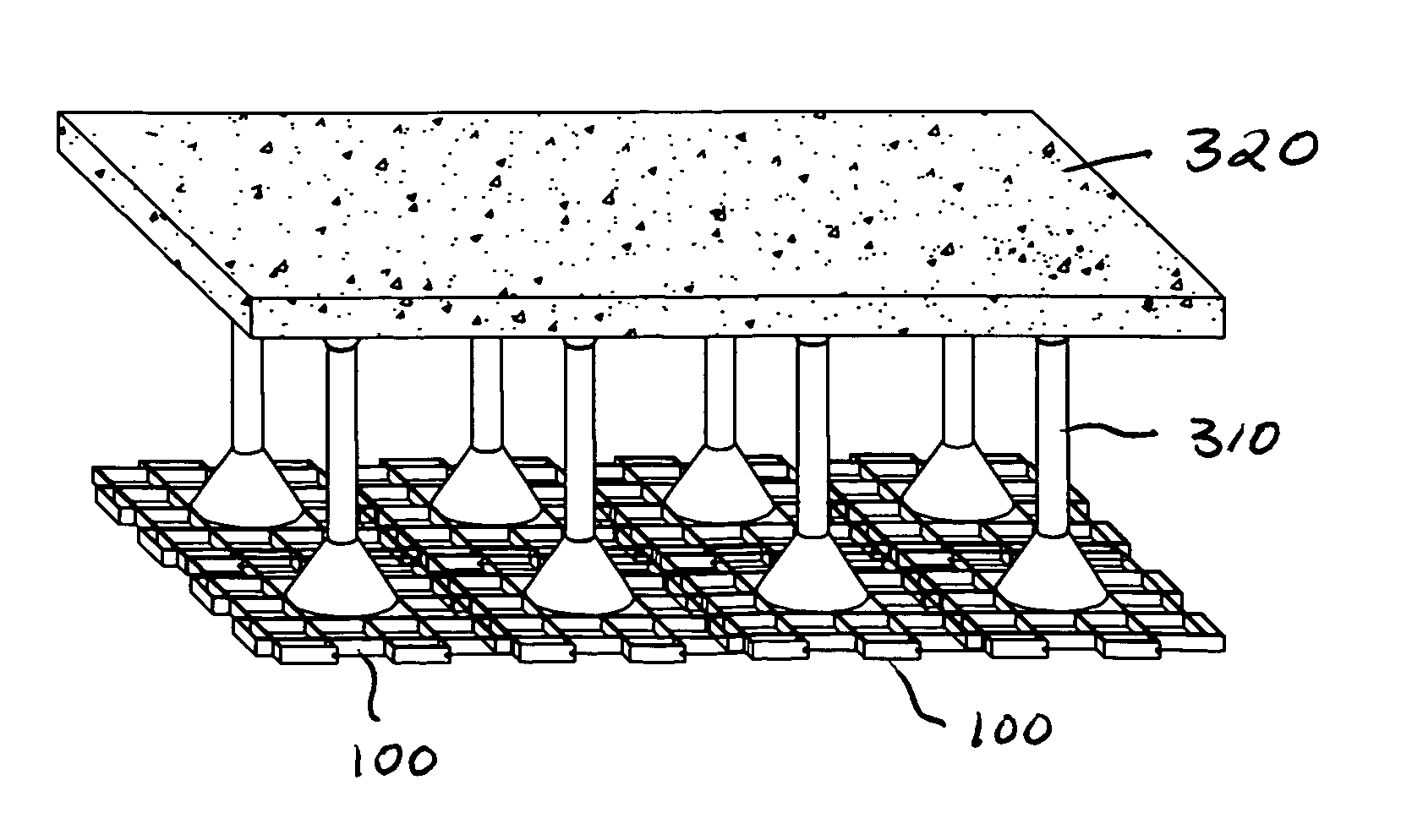

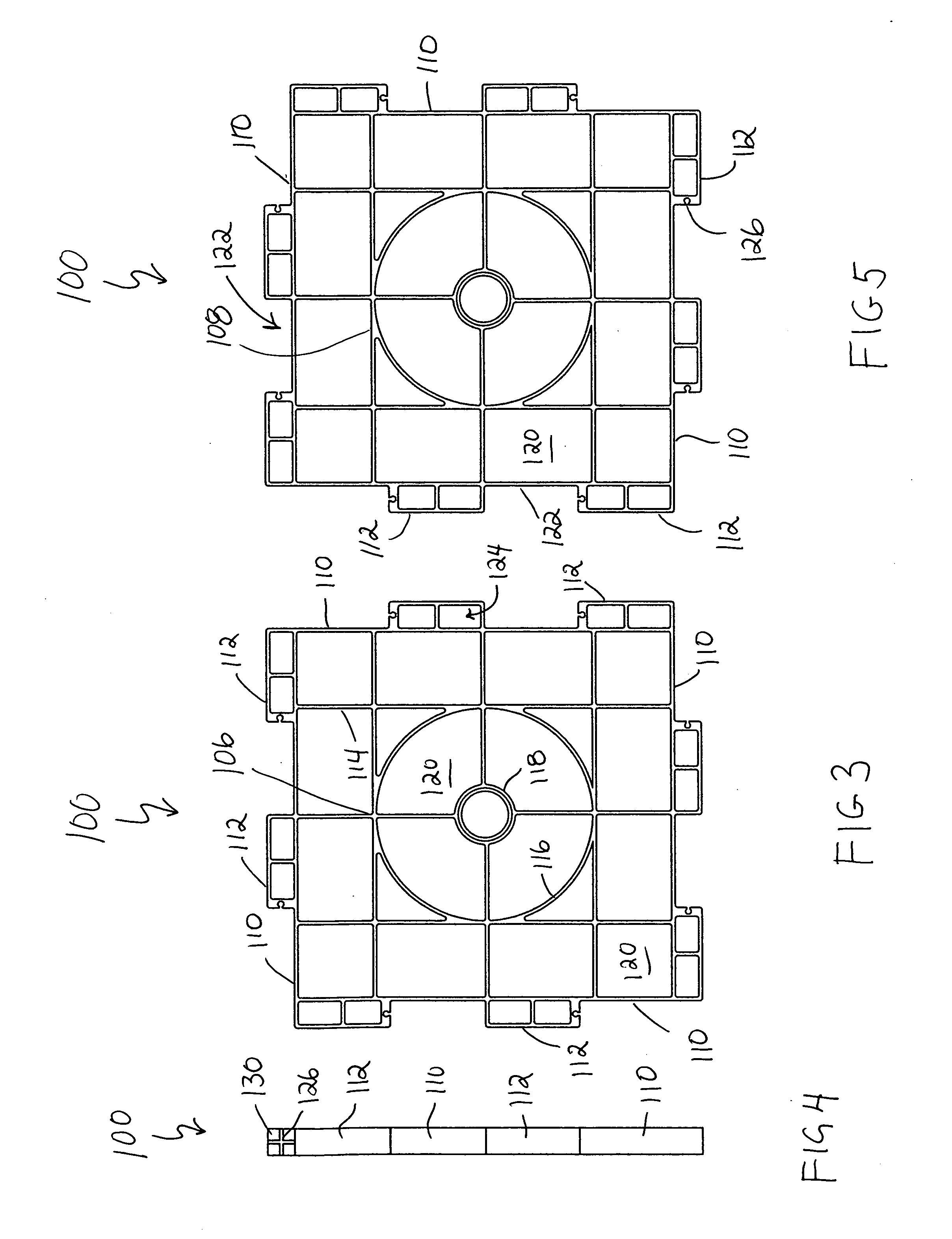

[0032]Disclosed herein are various embodiments of building panel structures and water detention / retention assemblies made therefrom. Reference will now be made in detail to the description of the embodiments as illustrated in the drawings, wherein like reference numbers indicate like parts throughout the several views.

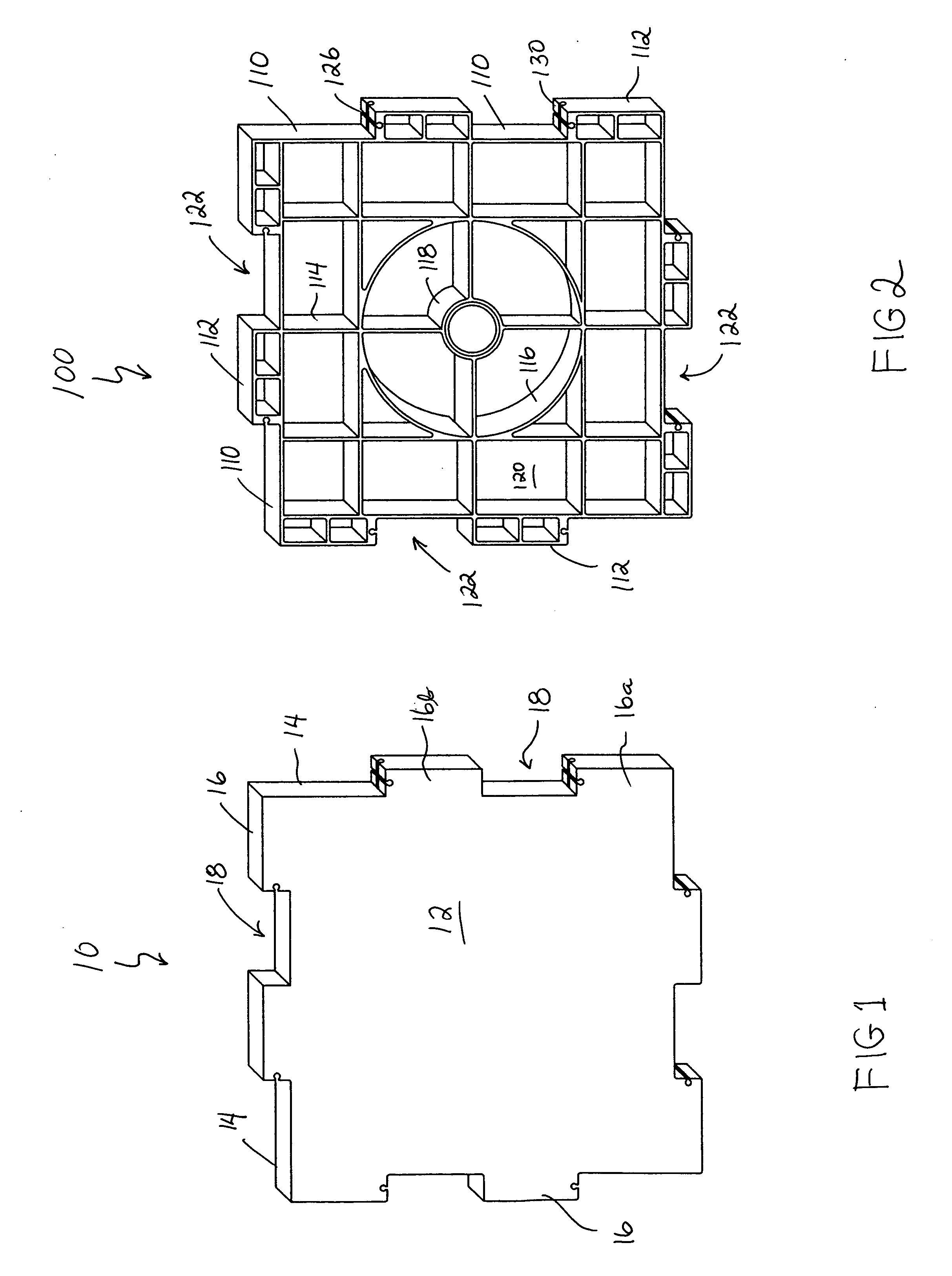

[0033]FIG. 1, illustrates a building panel 10 in accordance with the present invention. The panel 10 includes a front surface 12 and a rear surface (not shown) that is a mirror image of the front surface. The panel surface 12 is planar with side walls 14 around the periphery of the panel 10. Each side wall 14 has at least two connector tabs 16 and connector openings 18 between the tabs 16. The connector openings 18 are the same size as the tabs 16. On each side wall 14, a first one of the connector tabs 16a is located at the end of the side wall 14. A second connector tab 16b is located in a spaced relationship from the first tab 16a between the ends of the side wall 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com