Compression vapor engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

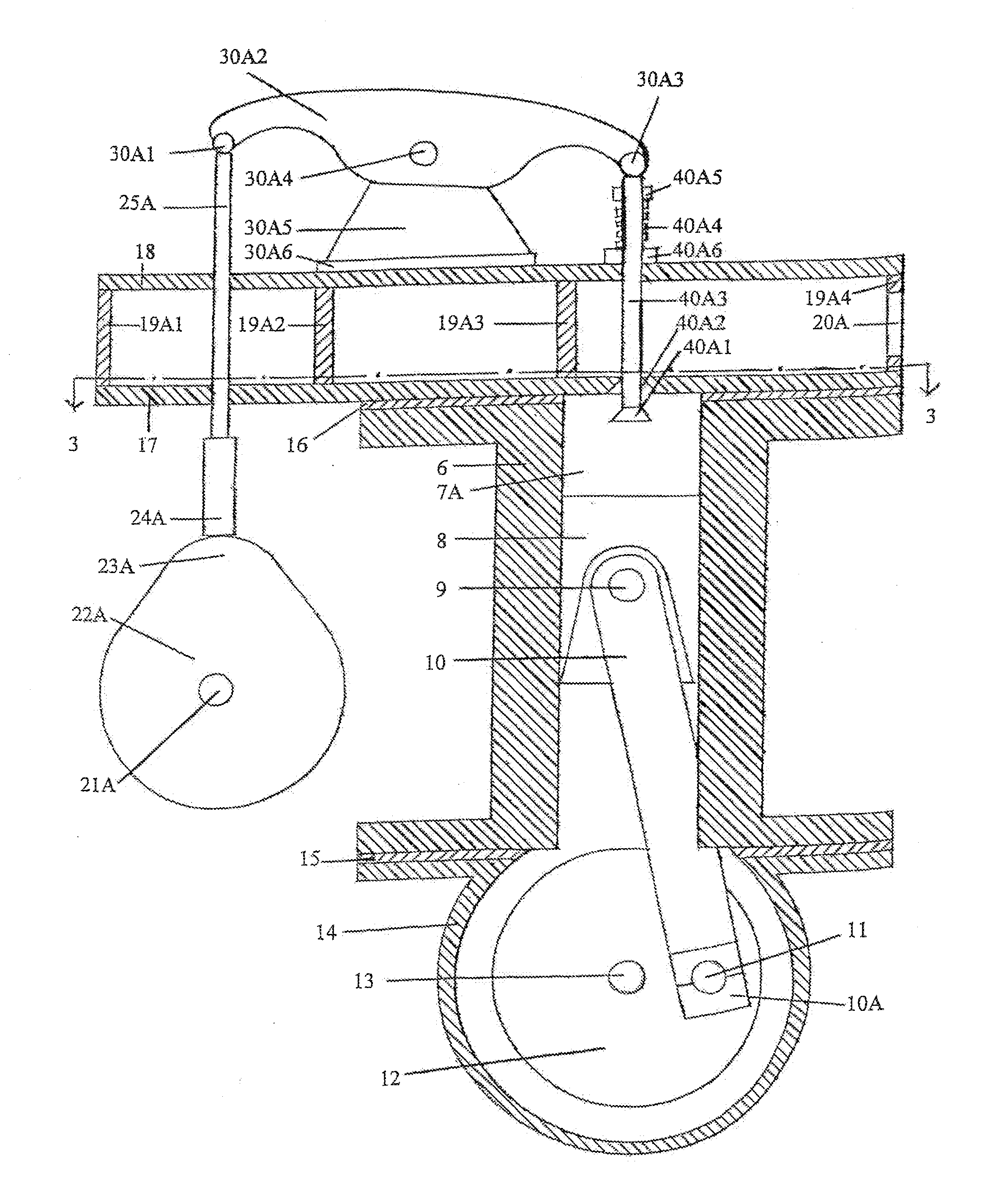

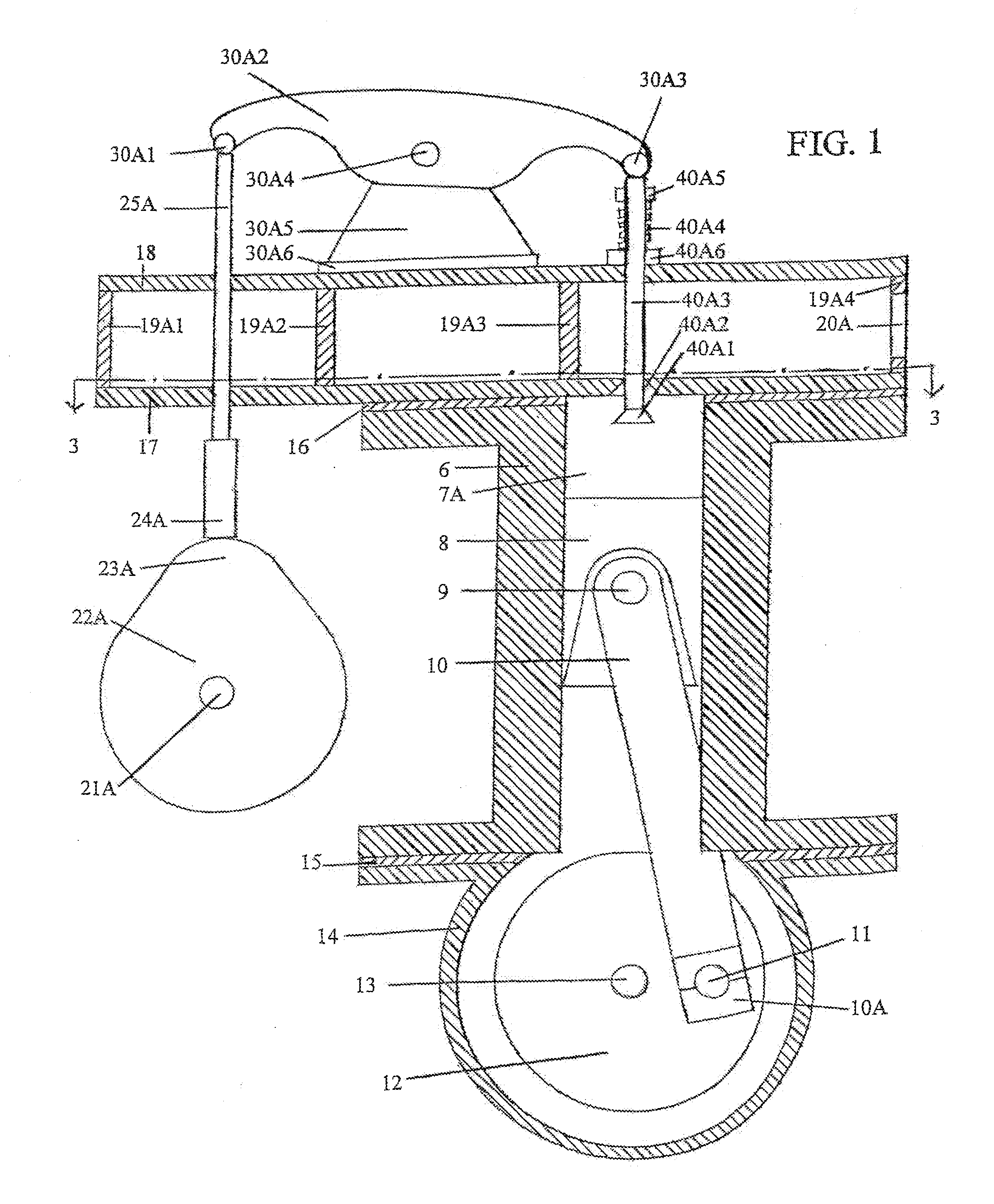

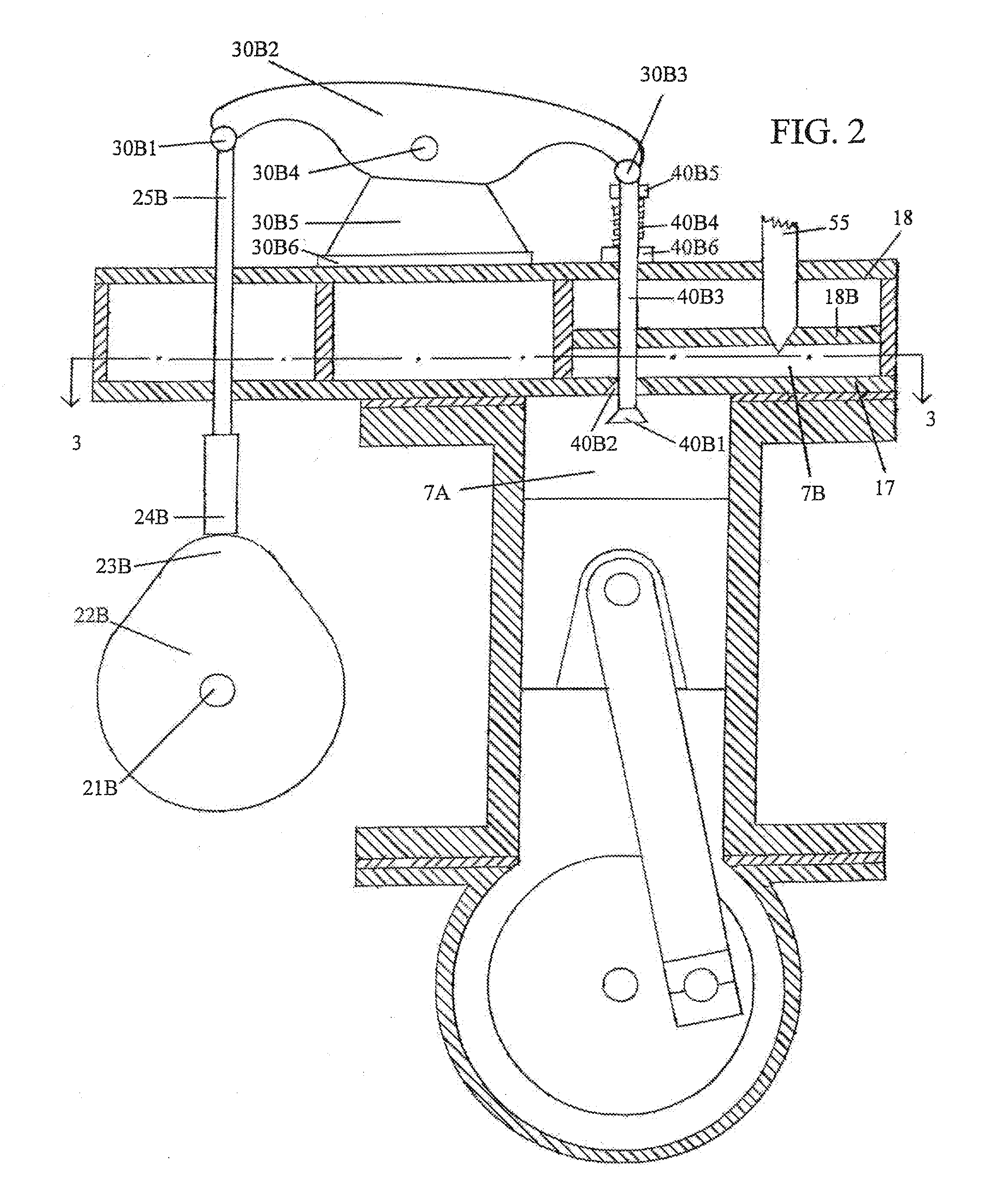

[0013]One preferred embodiment of the invention is as the well known four-stroke engine, though a two-stroke engine serves as well as another acceptable embodiment of the invention. The invention has a structure much like that of a compression-ignition engine, a “diesel” engine, and its operation is also rather imitative of such an engine. The three sheets of drawings which form the base for this detailed description present four figures of the engine's structure.

[0014]FIG. 1 shows the engine as the four-stroke embodiment, showing a sectional view of the engine seen from the front. The entire figure exhibits the three main areas of the engine. The central area is the core area of the engine, comprised of a cylinder block 6 enclosing a movable piston 8 in the “intake” stroke, the piston 8 midway in its motion downward. The upper area, known as the head, is the area where the operation of valves is performed and managed. The lower area, known as the crankcase area, is where the recipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com