Package

a technology for packaging and food, applied in the field of packaging, can solve the problems of insufficient moisture barrier properties and relatively low protective effect of the object to be packaged, and achieve the effects of high moisture barrier properties, enhanced moisture adsorption properties, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

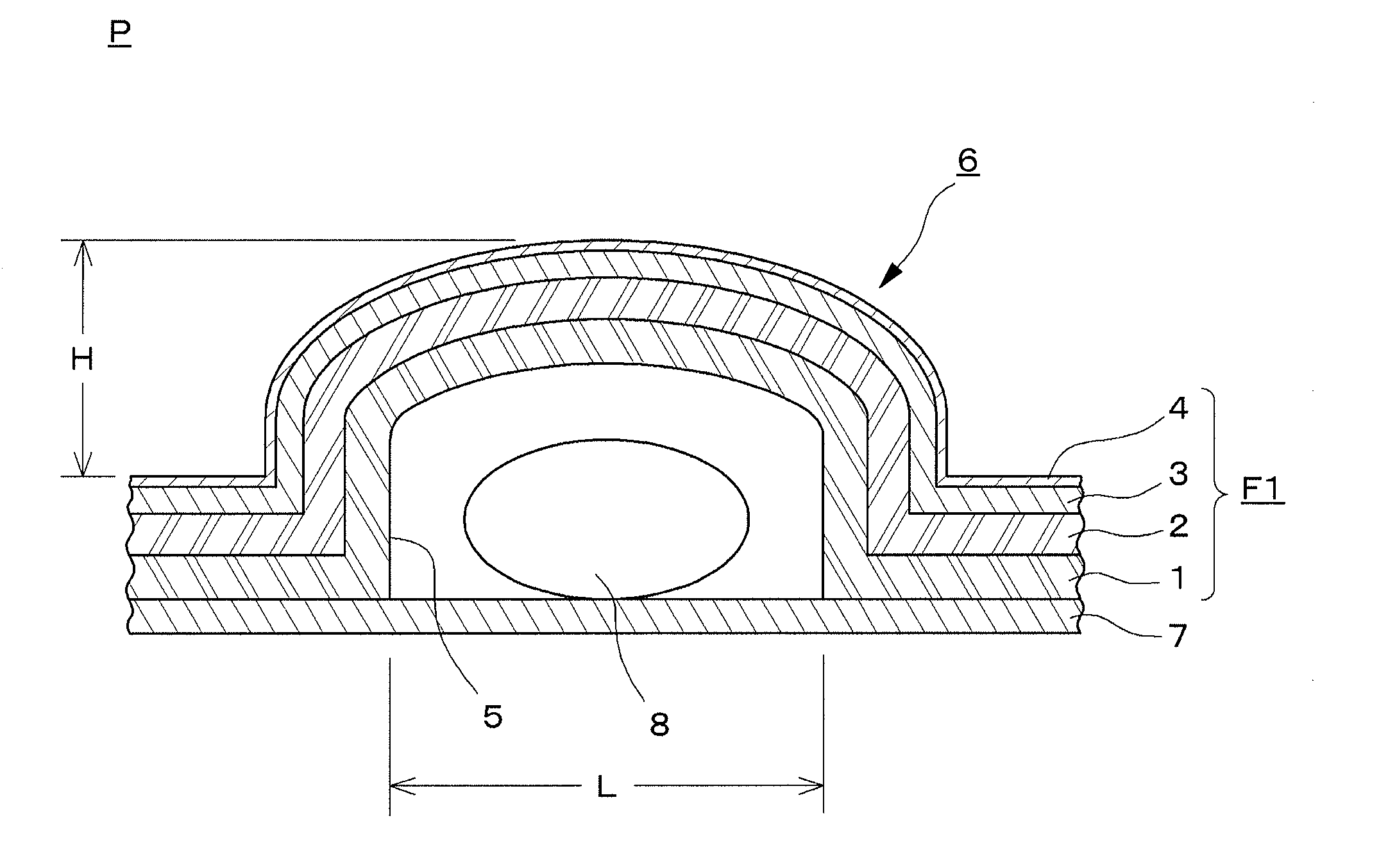

Configuration of Package Film F1

[0089]Adsorption layer 1: A two-component three-layer film in which a zeolite (manufactured by Union Showa K.K., trade name: MOLECULAR SIEVE 4A, effective pore diameter: 4 Å)-containing LDPE (manufactured by Tosoh Corp., trade name: PETROTHENE 202, thickness: 50 μm) layer is laminated on both surfaces with a skin layer of LLDPE (manufactured by Prime Polymer Co., Ltd., trade name: EVOLUE (registered trademark) SP2520)

[0090]Substrate layer 2: PVC (polyvinyl chloride) (thickness: 60 μm)

[0091]Aluminum foil 3: An aluminum alloy foil (manufactured by Sumikei Aluminum Foil Co., Ltd., trade name: BESPAII, thickness: 40 μm)

[0092]Barrier layer 4: PA (polyamide-based resin) (manufactured by Toyobo Co., Ltd., trade name: HARDEN N2102, thickness: 15 μm)

example 3

Configuration of Package Film F1

[0100]Adsorption layer 1: A two-component three-layer film in which a zeolite (manufactured by Union Showa K.K., trade name: MOLECULAR SIEVE 4A, effective pore diameter: 4 Å)-containing LDPE (manufactured by Tosoh Corp., trade name: PETROTHENE 202, thickness: 130 μm) layer is laminated on both surfaces with a skin layer of LLDPE (manufactured by Prime Polymer Co., Ltd., trade name: EVOLUE (registered trademark) SP2520)

[0101]Substrate layer 2: PA (polyamide-based resin) (Manufactured by Kohjin Holdings Co., Ltd., trade name: BONYL W, thickness: 15 μm)

[0102]Aluminum foil 3: An aluminum alloy foil (manufactured by Toyo Aluminum K.K., trade name: SUPERFOIL, thickness: 40 μm)

[0103]Barrier layer 4: PA (polyamide-based resin) (manufactured by Kohjin Holdings Co., Ltd., trade name: BONYL W, thickness: 15 μm)

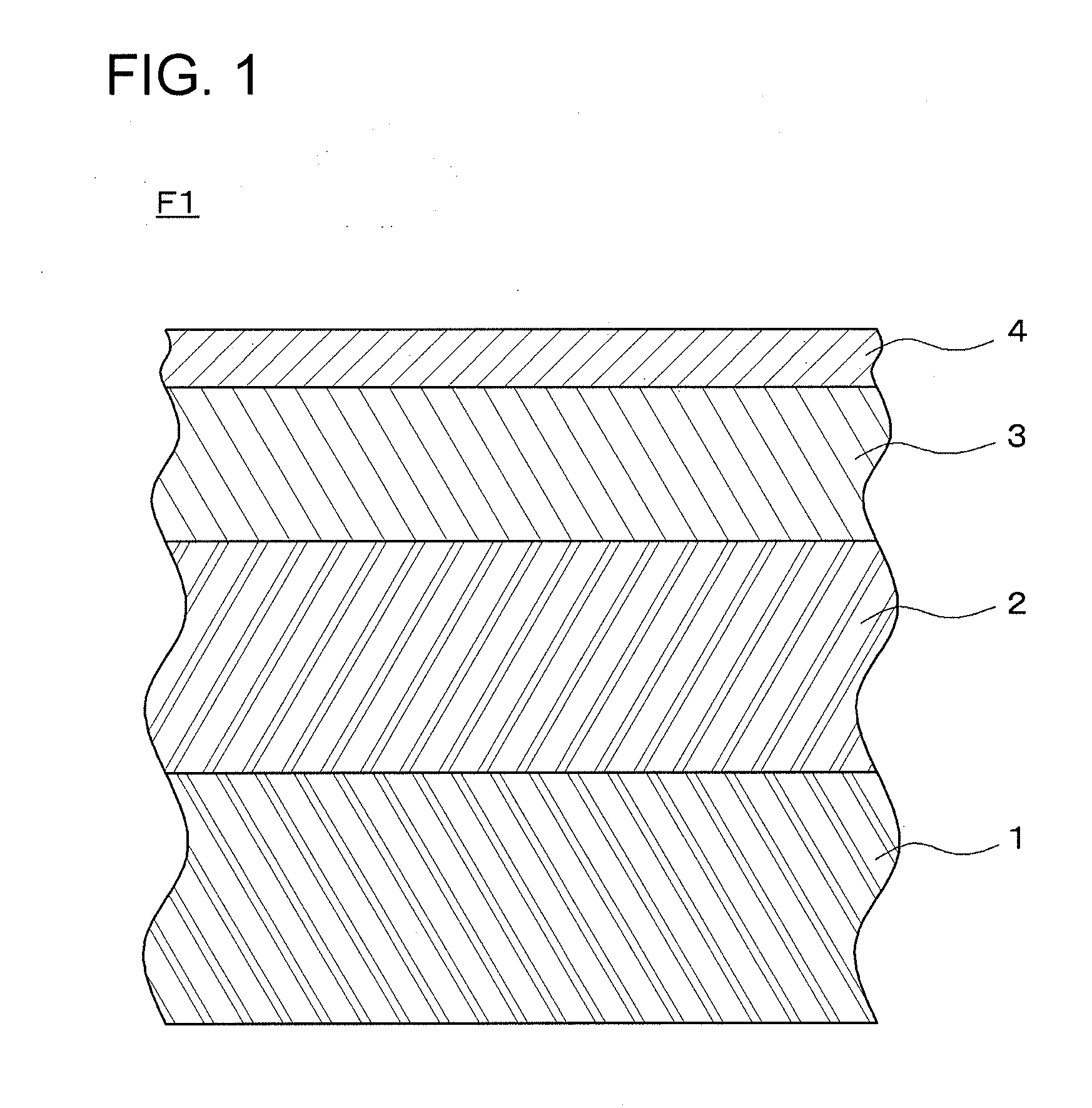

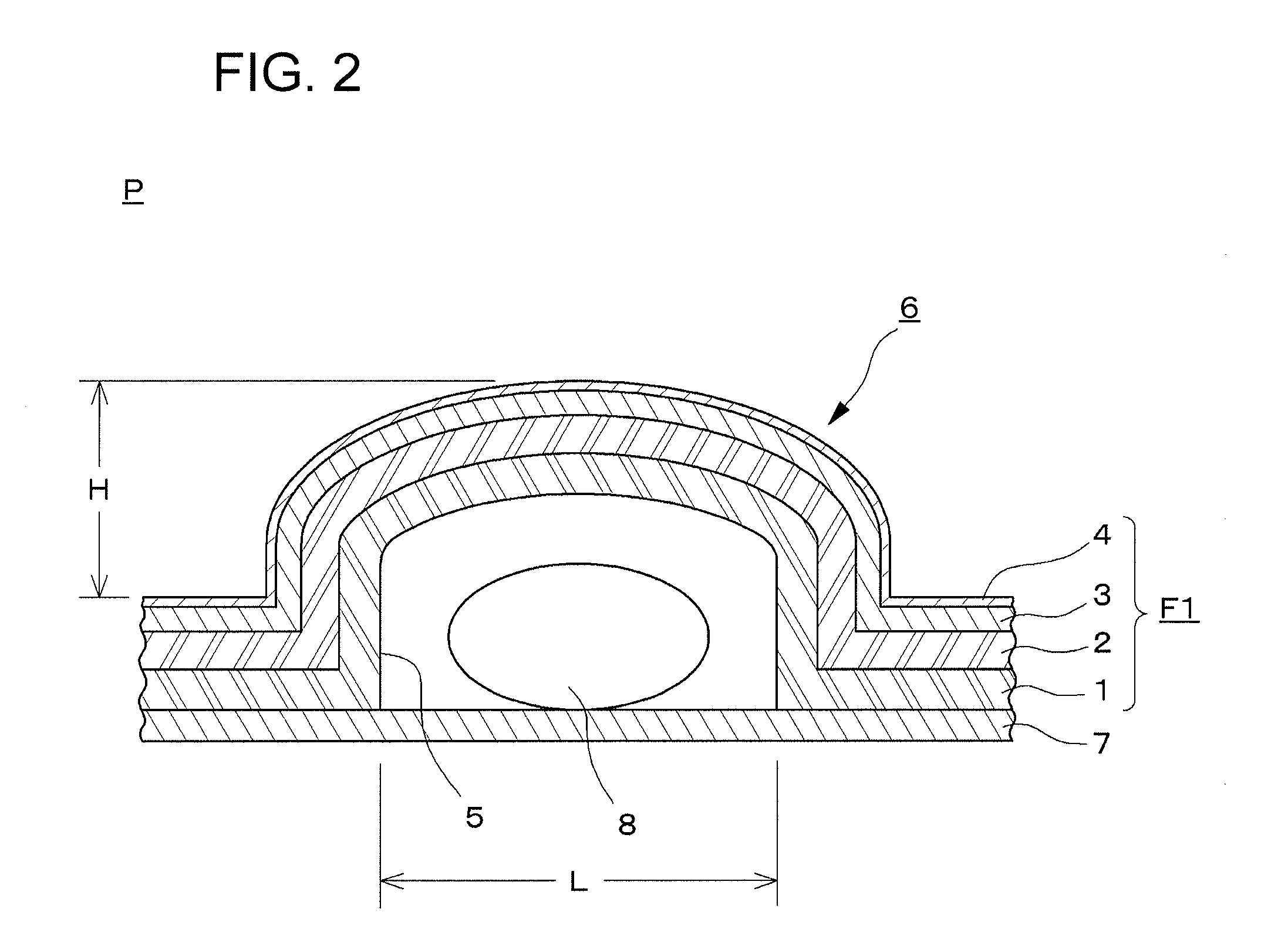

example 1

[0124]The solid preparation 8 obtained in the Preparation Example above was sealed in by bonding a container sheet 6 formed from a package film F1 having the following configuration with a cover material sheet 7 formed by aluminum, and thereby a package P was obtained. Meanwhile, since the configuration of the package film F1 that constitutes the container sheet 6 of Example 1 is the same as the configuration used in Example 1 as described above, further explanation will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com