Gas turbine exhaust diffuser having plasma actuator

a technology of plasma actuator and exhaust diffuser, which is applied in the direction of engine control, machine/engine, stators, etc., can solve the problems of pressure loss and general consumption of exhaust diffuser spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

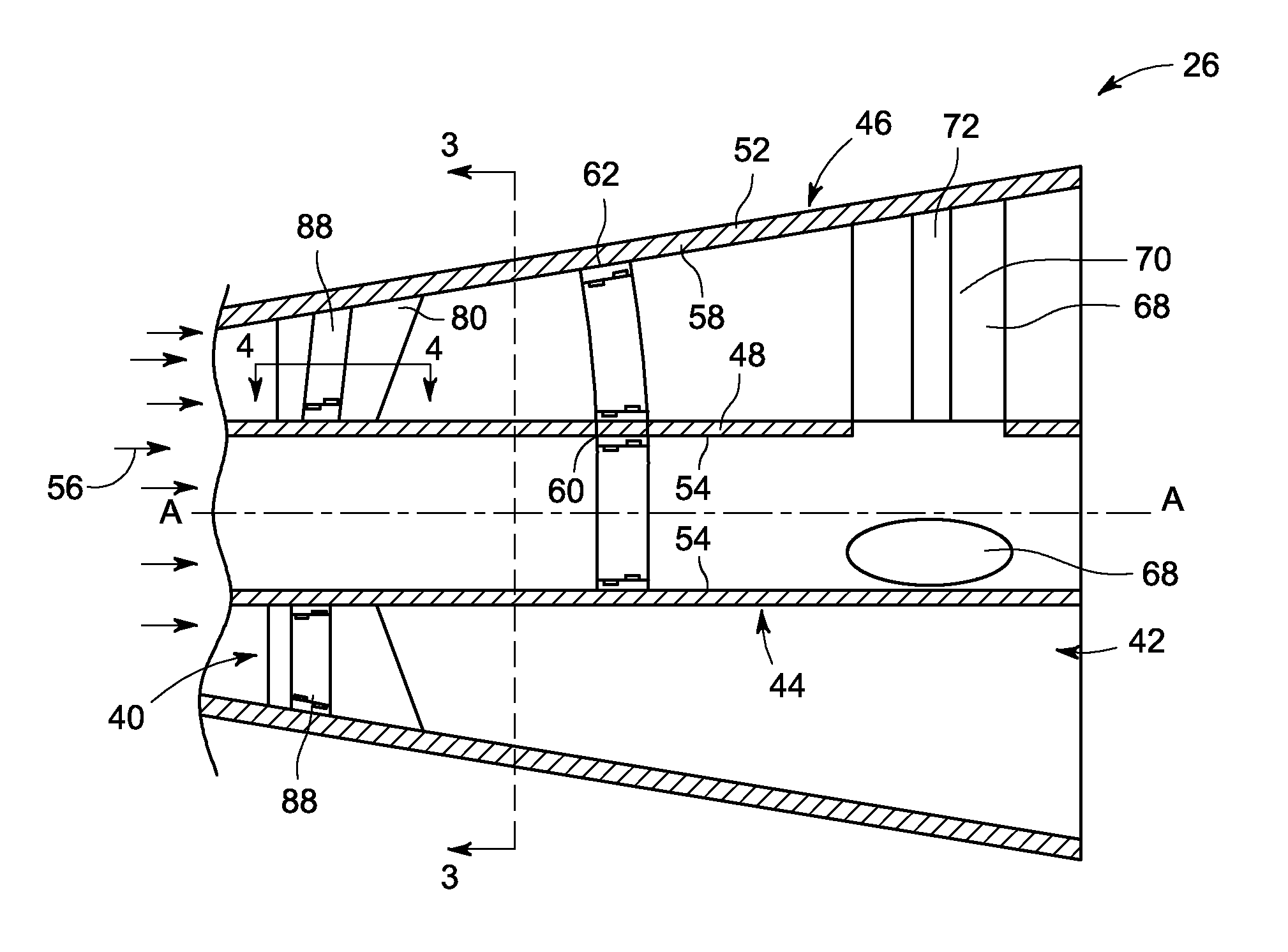

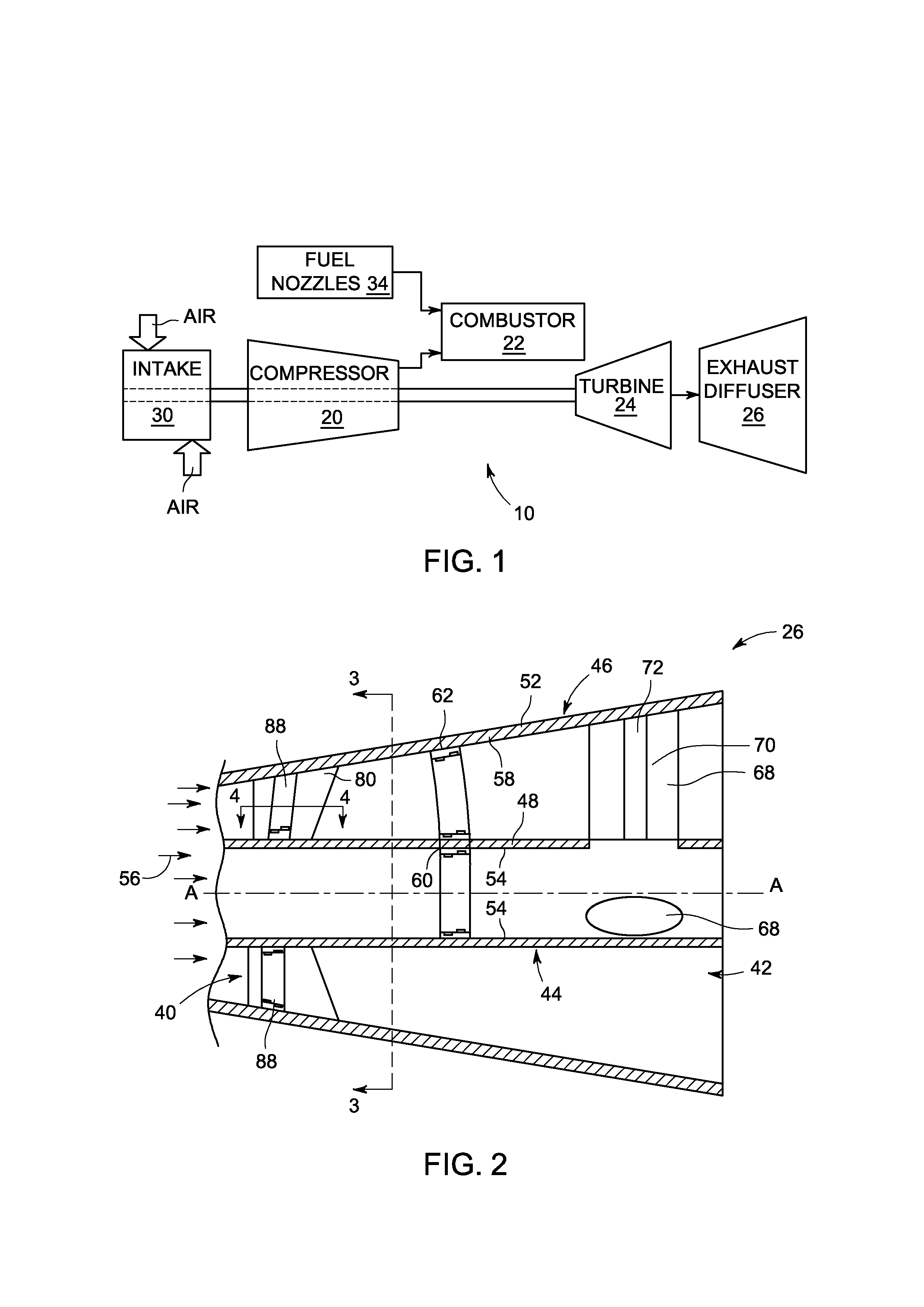

[0013]FIG. 1 illustrates a schematic exemplary power generation system indicated by reference number 10. The power generation system 10 is a gas turbine system having a compressor 20, a combustor 22, a turbine 24, and an exhaust diffuser 26. Air enters the power generation system 10 though an air intake 30 connected to the compressor 20, and is compressed by the compressor 20. The compressed air is then mixed with fuel by a fuel nozzle 34 in a specific ratio for combustion. The combustion generates hot pressurized exhaust gas that drives blades (not shown) that are located within the turbine 24. The exhaust gas is sent from the turbine 24 to the exhaust diffuser 26.

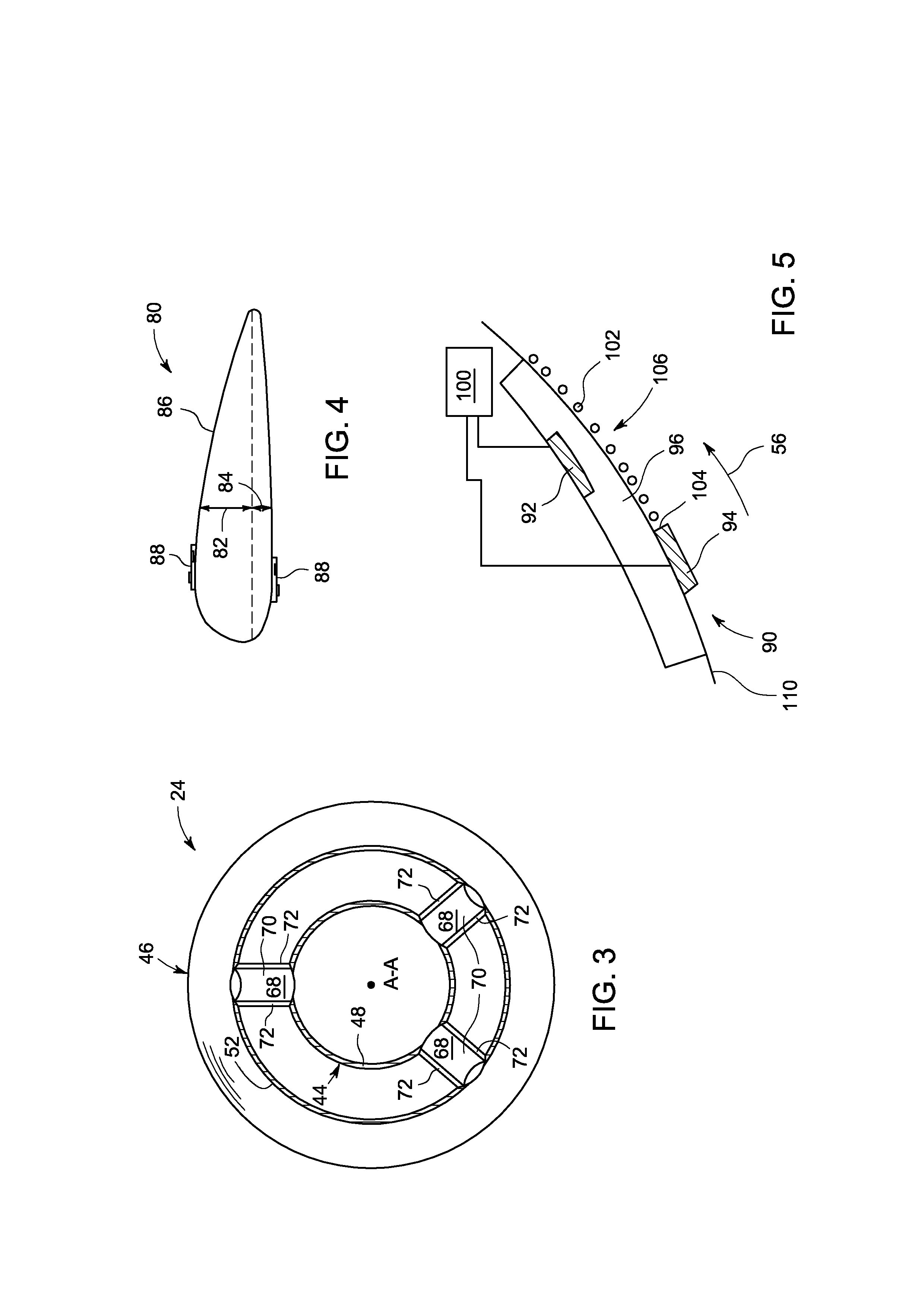

[0014]FIG. 2 is an exemplary illustration of a side view of the exhaust diffuser 26. The exhaust diffuser 26 includes an inlet 40, an outlet 42, an inner diffuser 44 and an outer diffuser 46. The inner diffuser 44 includes an inner wall 48 and the outer diffuser 50 includes an outer wall 52. The inner wall 48 and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com