Plasma cooling heat sink

a technology of heat sink and plasma, which is applied in the direction of heat transfer modification, indirect heat exchanger, lighting and heating apparatus, etc., can solve the problems of reducing the lifespan of these devices, consuming higher electricity for cooling, and generating significant heat for electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

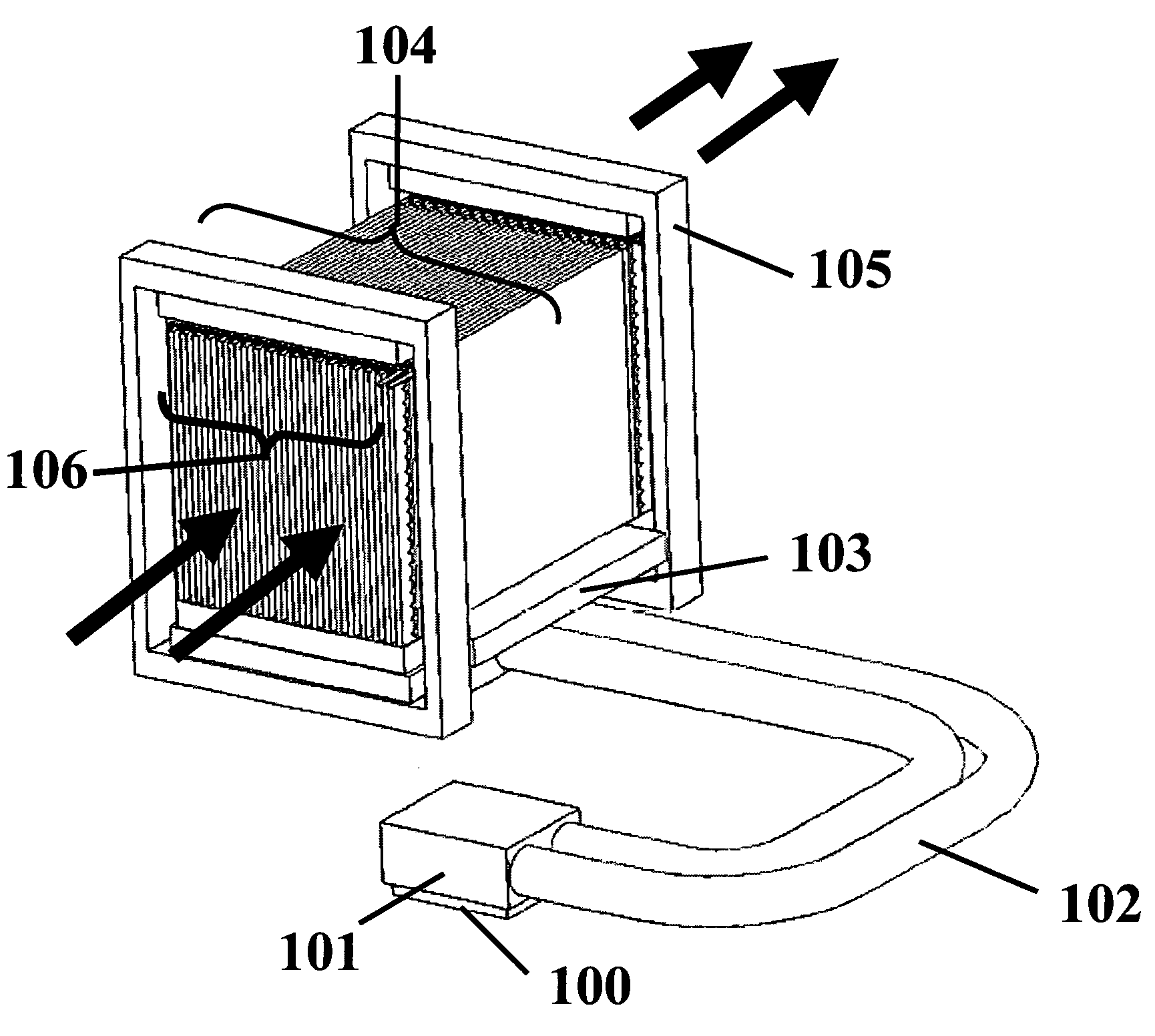

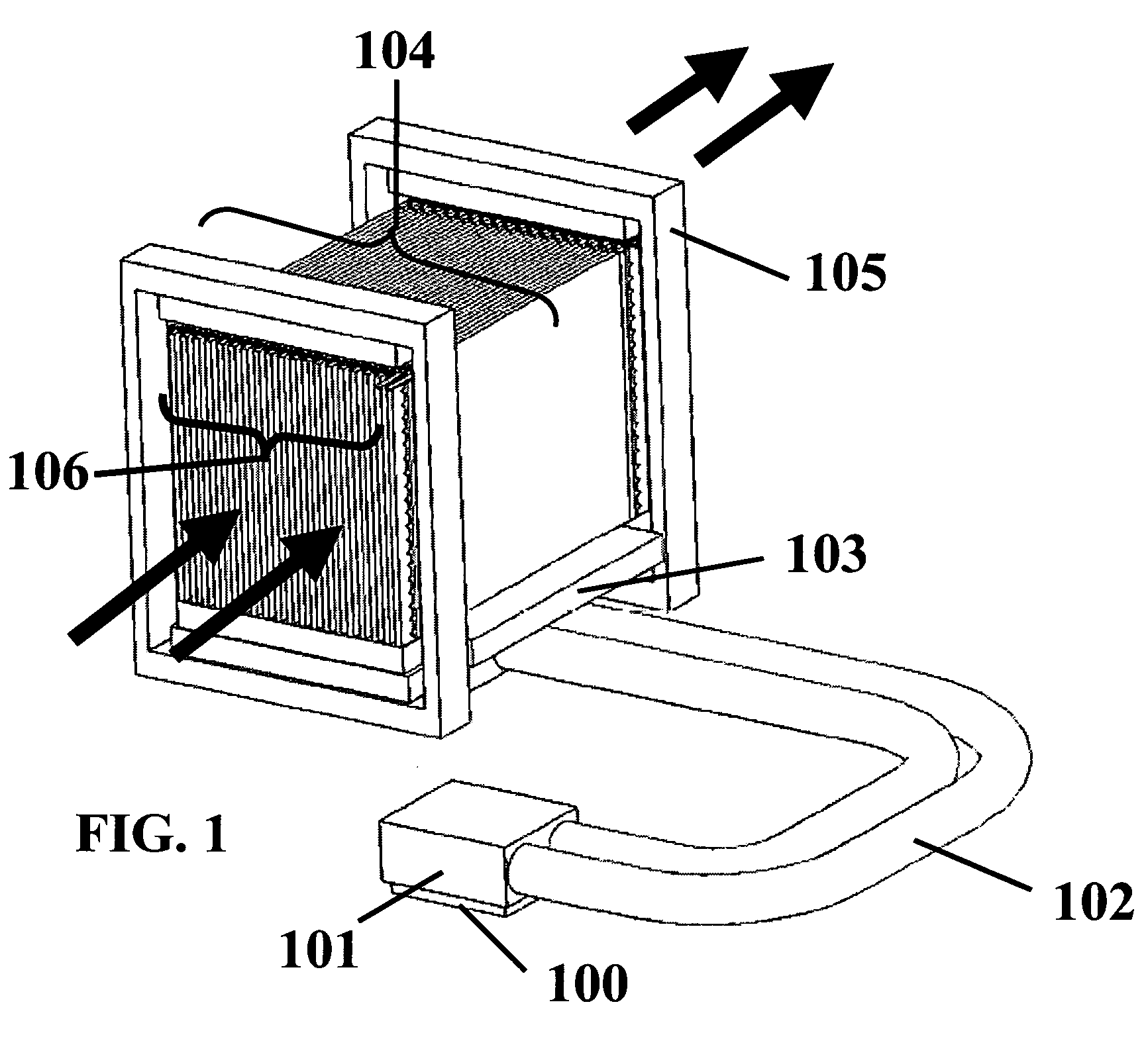

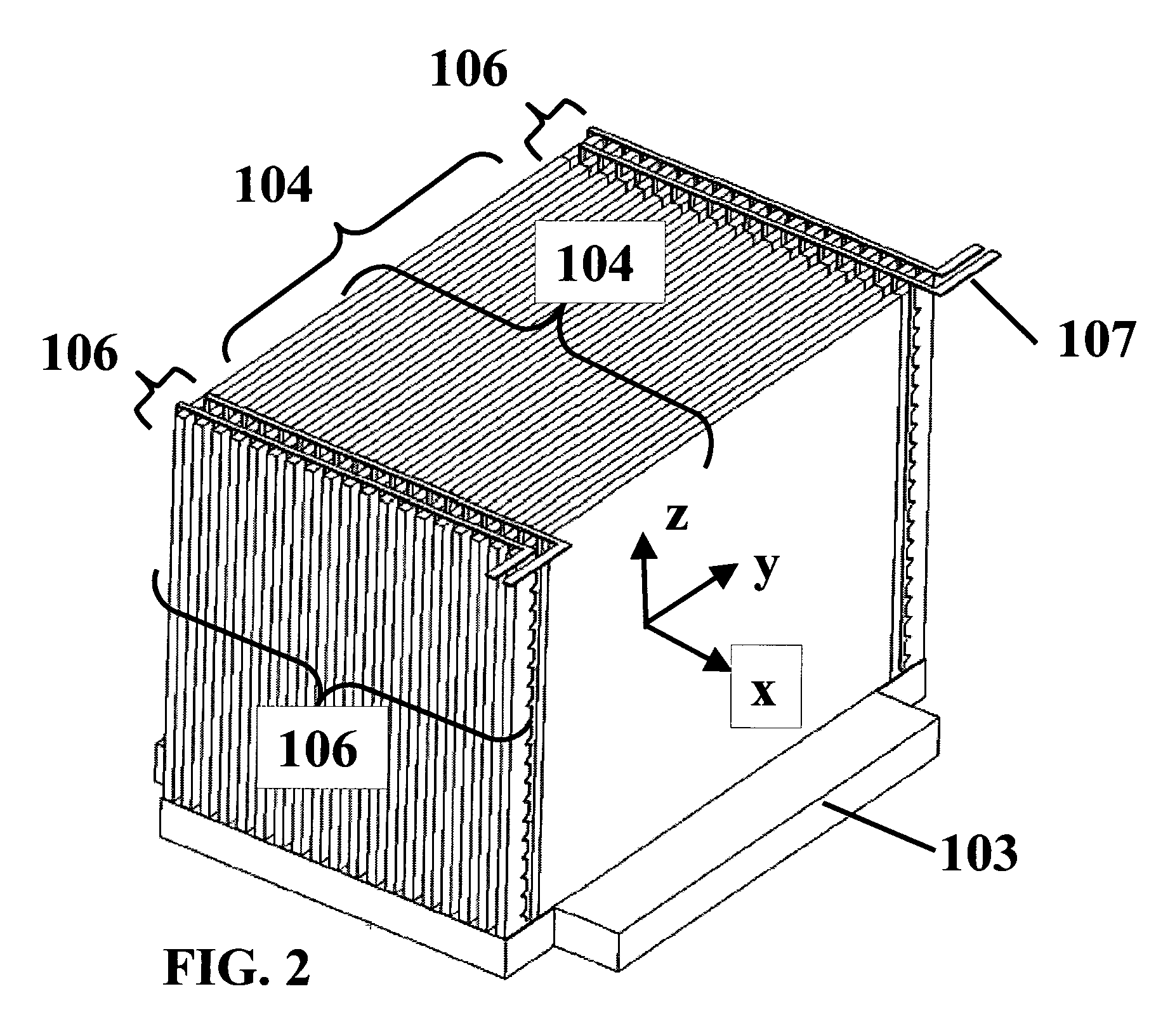

[0036]The invention generally relates to apparatus for cooling microelectronic devices or packages, such as microprocessors, and ASIC. Such systems and methods may be used in a variety of applications. A non-exhaustive list of such applications includes the cooling of: a microprocessor chip, a graphics processor chip, an ASIC chip, a video processor chip, a DSP chip, a memory chip, a hard disk drive, a graphic card, a portable testing electronics, a personal computer system.

[0037]Take laptop computer for example, conventional fans use a lot of space and energy. For this reason, the plasma-driven cooling device represents a way to increase their cooling capacity and make them more reliable and far quieter. Therefore the higher-performance chips that generate too much heat for current laptops can be used.

[0038]As used herein “plasma” is an ionized gas, a gas into which sufficient energy is provided to free electrons from atoms or molecules and to allow both species, ions and electrons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com