Ergonomic footwear

a technology of ergonomic footwear and footbed, applied in the field of footbeds, can solve the problems of ineffective improvement of wearer's walking smoothness of conventional footwear, and achieve the effects of enhancing wearer's walking smoothness, facilitating stable tread of wearer's sole, and improving the flexibility of outsoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

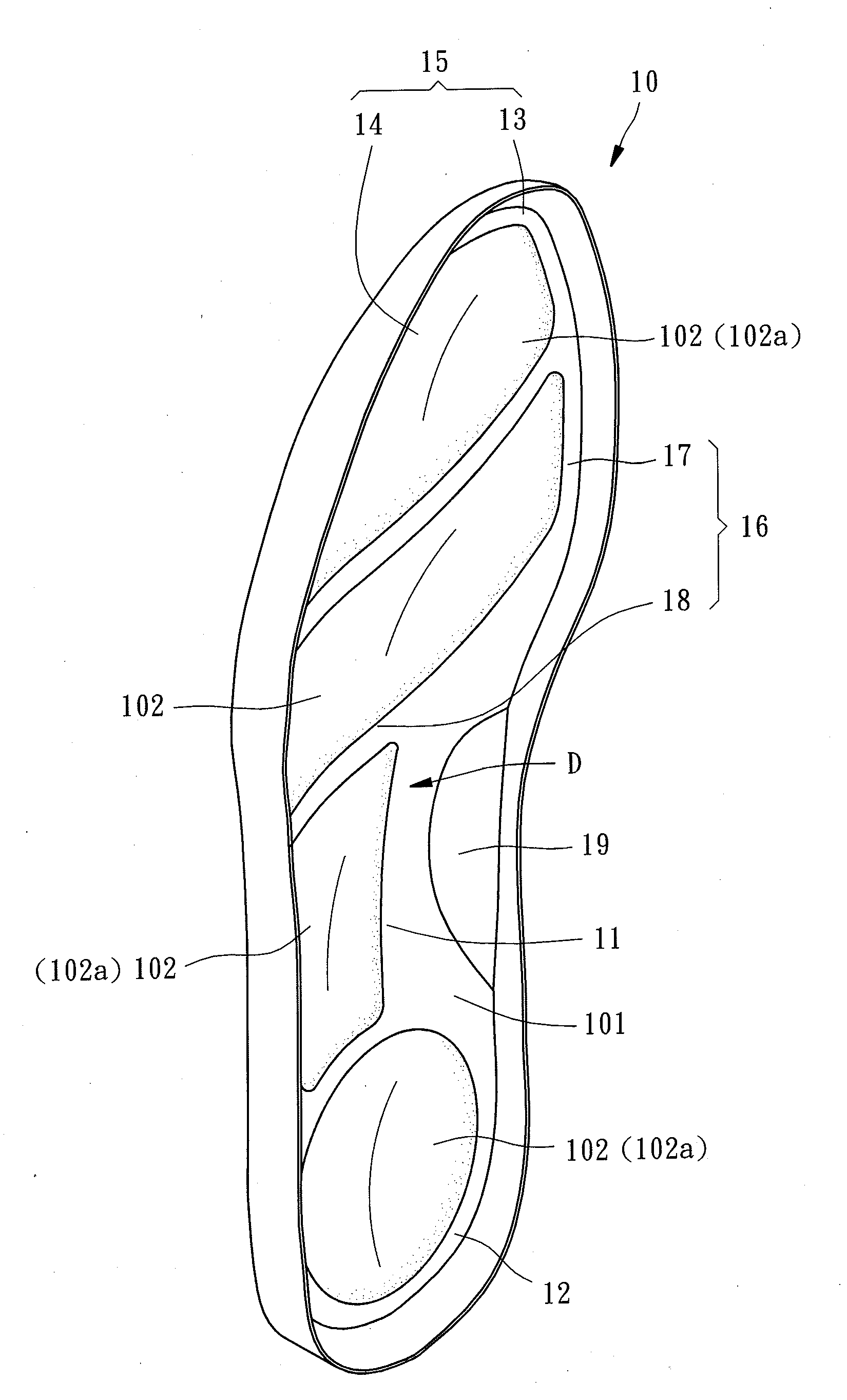

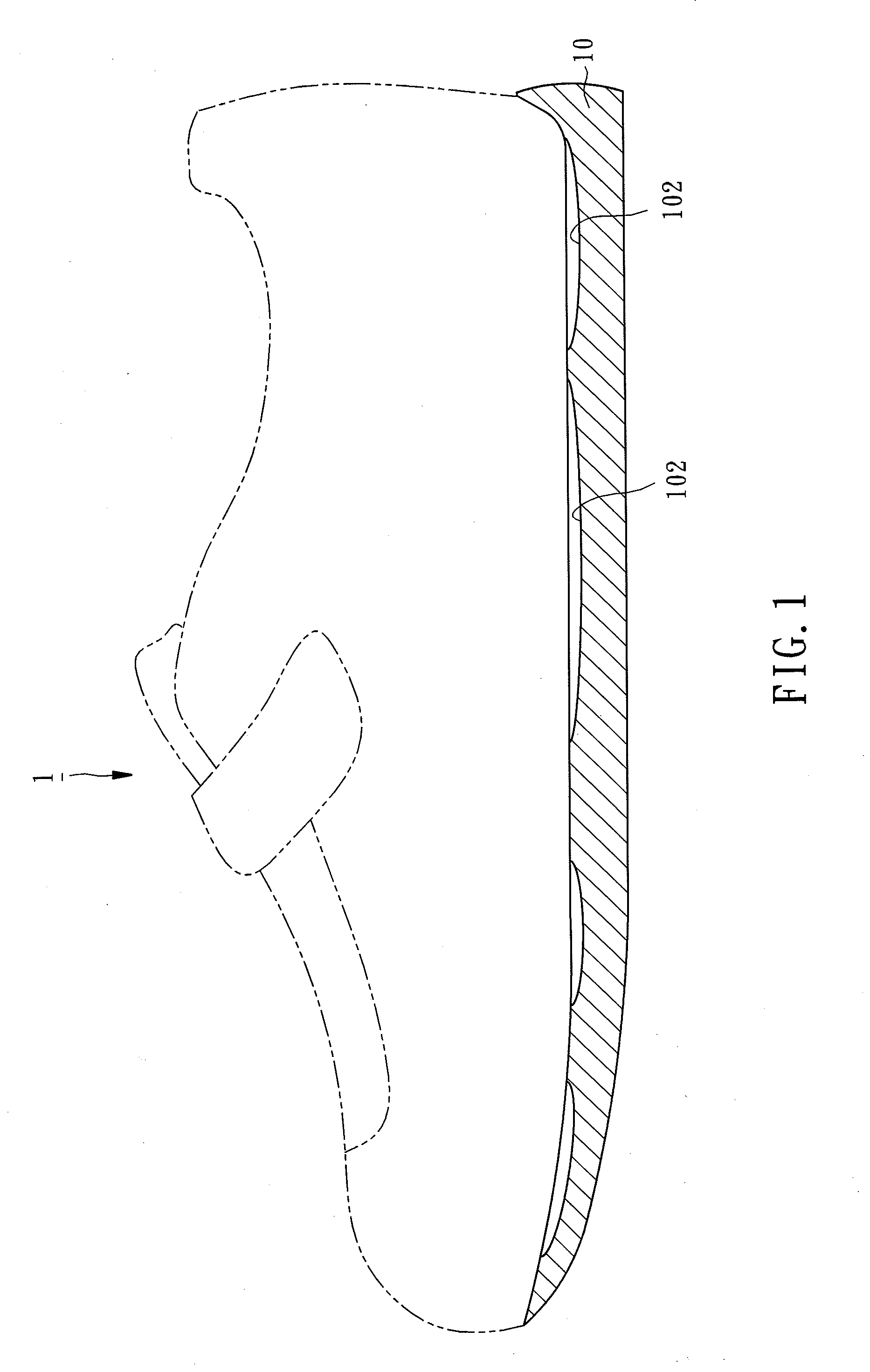

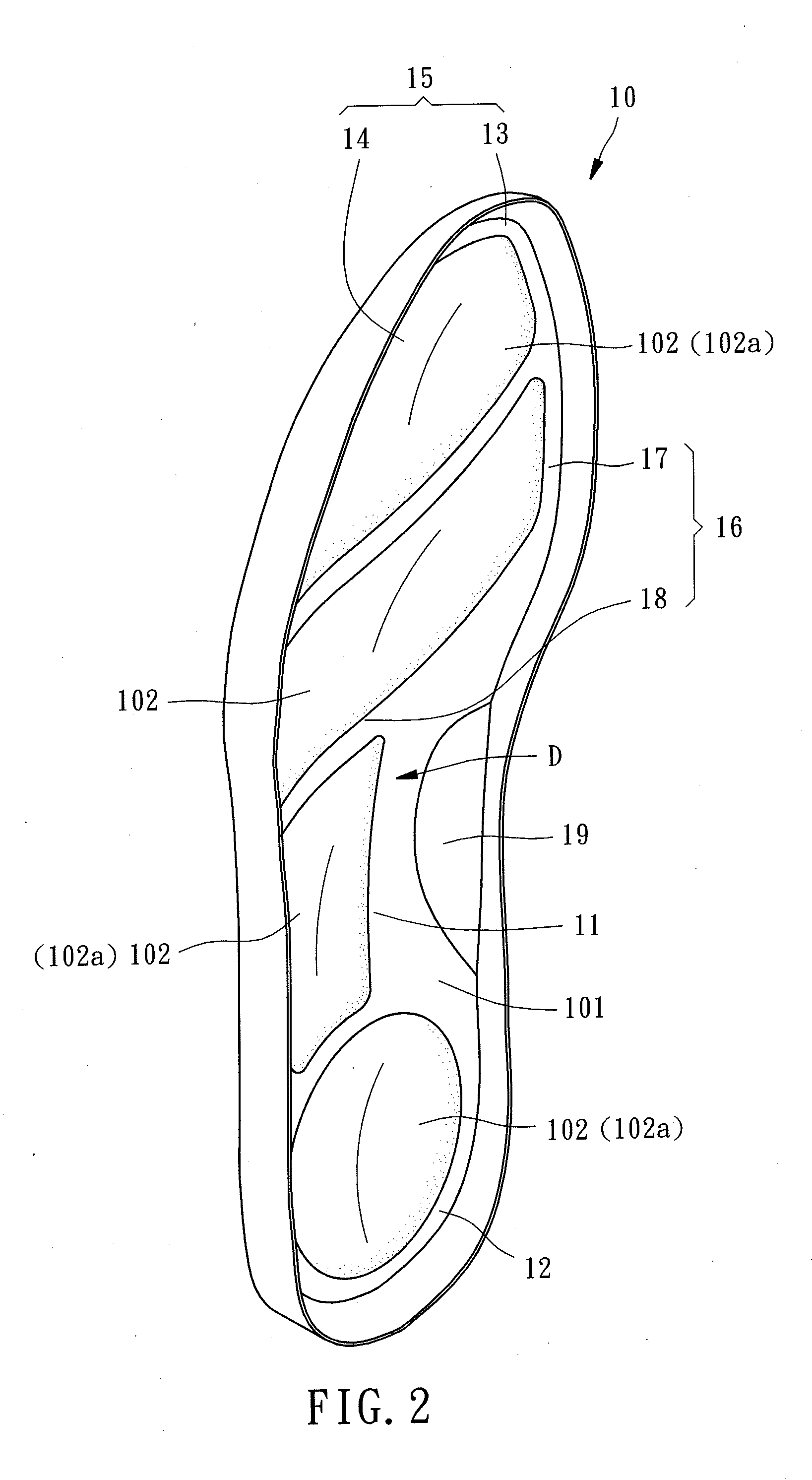

[0053]Referring first to FIG. 1, according to the present invention, an ergonomic footwear 1 primarily comprises an outsole 10.

[0054]The outsole 10 is made of a PU foam material and possesses resilience. Of course, in practical manufacturing, the outsole 10 may be made of any materials known to be used in making footwear outsoles, such as latex or thermoplastic rubber (TPR). As shown in FIG. 2, the outsole 10 may be divided, according to regions of a human foot sole that apply treading force, into an inner arch segment 19, an outer arch segment 11, a heel segment 12 that is located behind the outer arch segment 11, an inner toe segment 13 that is located in front of the outer arch segment 11 and corresponds to the human, an outer toe segment 14 that is located in front of the outer arch segment 11 and corresponds to the second through fourth toes, a toe segment 15 comprising the inner and outer toe segments 13, 14, a metatarsus segment 16 that is located between the outer arch segme...

third embodiment

[0058]Now referring to FIG. 11, in the present invention, the footwear 1 comprises the outsole 10 and a pad which is a midsole 30 in this embodiment. The outsole 10 is configured according to the above embodiments and thus needs not to be discussed in any length herein.

[0059]The midsole 30 is deposited on the top surface 101 of the outsole 10. As shown in FIG. 12, the top surface 301 of the midsole 30 includes a datum plane D, and a plurality of contacting portions 302 that are configured to be different from the datum plane D in terms of elevation. In FIG. 12, the contacting portion 302 are top-surface depressions 302a depressed downward from the top surface 301 of the midsole 30 and located corresponding to the outer arch segment 11, the heel segment 12, the toe segment 15 and the metatarsus segment 16 of the outsole 10, respectively. Also, as shown in FIG. 11, each of the top-surface depressions 302a are corresponding to one said top-surface depression 102a of the outsole 10, res...

fourth embodiment

[0061]Referring to FIG. 15, in the present invention, the footwear 1 comprises the outsole 10 and a pad which is an insole 40 in this embodiment. The detailed description of the outsole 10 is herein omitted for eliminating repetition.

[0062]The insole 40 is deposited on the top surface 101 of the outsole 10. As shown in FIG. 15 and FIG. 16, the insole 40 has a plurality of hollow bowls 402 corresponding to the outer arch segment 11, the heel segment 12, the toe segment 15 and the metatarsus segment 16 of the outsole 10, respectively, and corresponding to the top-surface depression 102a of the outsole 10, respectively. Additionally, in FIG. 15, the hollow bowls 402 each have a sagged surface 402a integrally depressed from the top surface 401 of the insole and a raised surface 402b that corresponds to the sagged surface 402a and integrally raised from the bottom surface of the insole 403. Thus, when a wear wears the footwear and walks, force-exerting regions of his / her foot sole can si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com