Flicker-Free LED Driver Circuit with High Power Factor

a led driver circuit and power factor technology, applied in the field of ac led driver circuits, can solve the problems of reducing the power factor of the conventional led driver circuit, the difficulty of using the conventional ac outlet, and the distortion of the photos, so as to solve the flickering problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

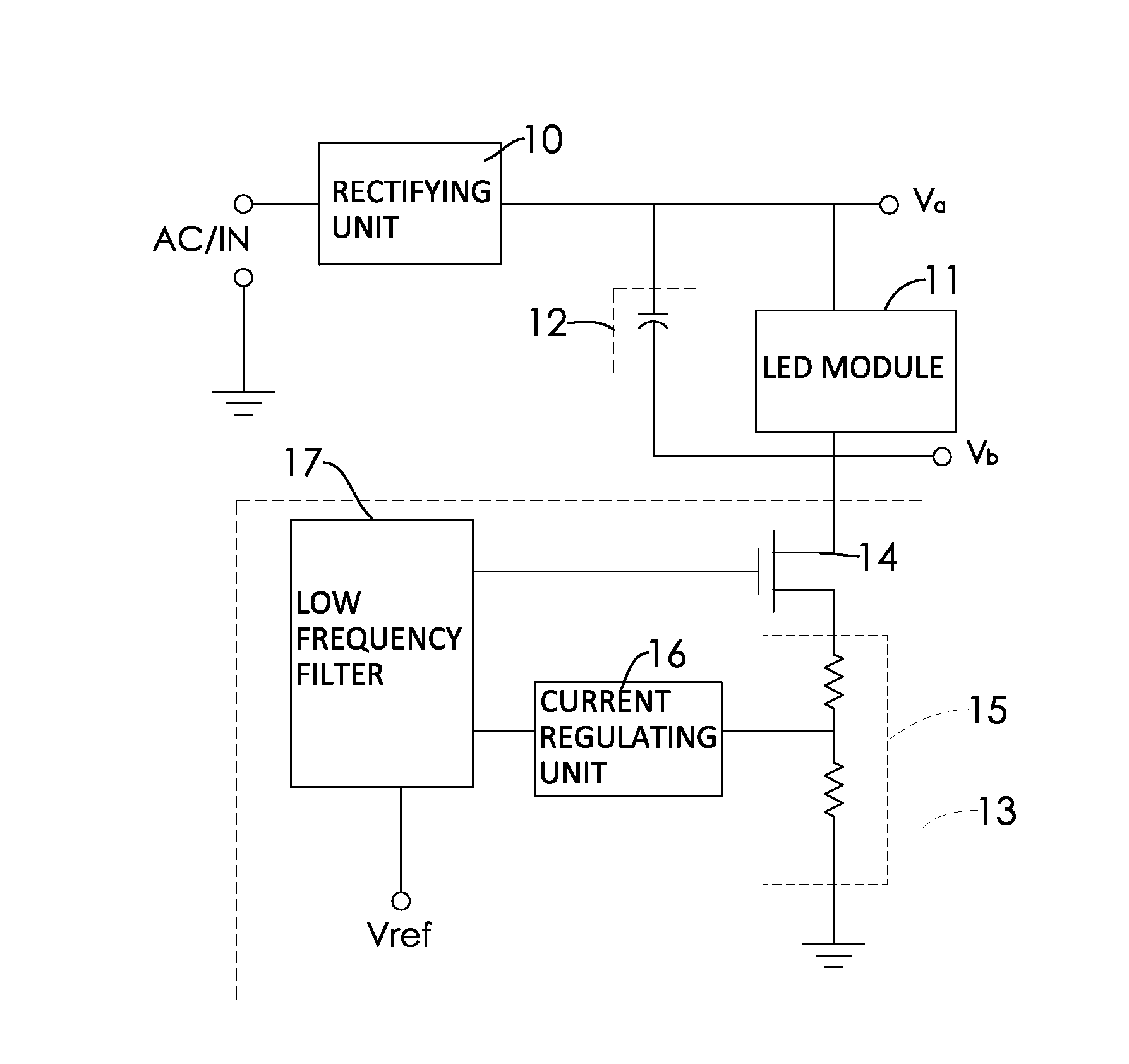

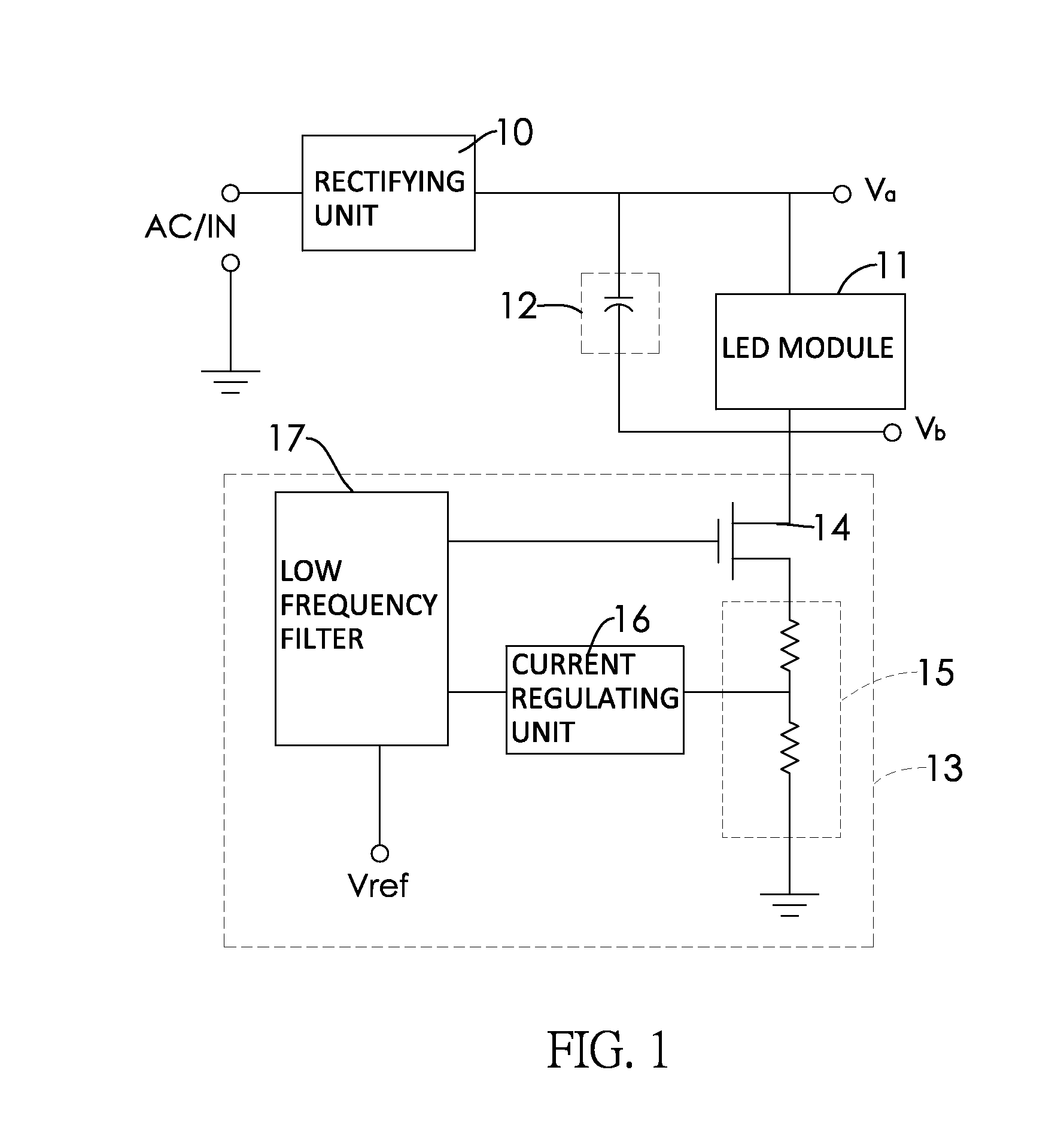

[0032]FIG. 1 shows the flicker-free LED driver circuit with a high power factor. The circuit comprises a rectifying unit 10, an LED module 11, a capacitor module 12, and a constant current circuit 13.

[0033]The input terminal of the rectifying unit 10 connects to an AC power supply AC / IN, and converts the AC power supply AC / IN into a pulsed DC power supply, which is then output by the output terminal thereof. The rectifying unit 10 can be a full-wave rectifying circuit or a half-wave rectifying circuit. In this embodiment, it is a full-wave rectifying circuit.

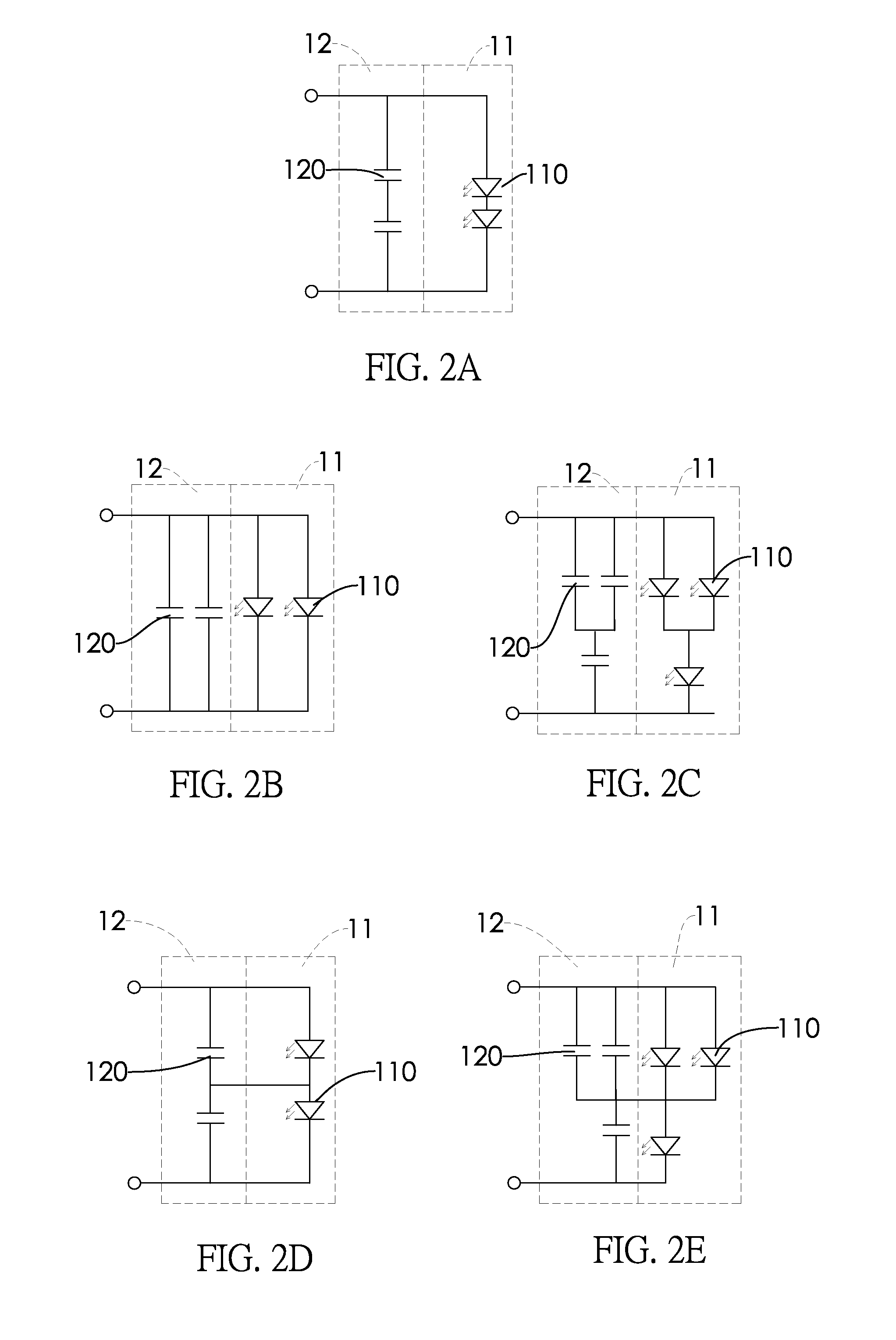

[0034]The LED module 11, as shown in FIGS. 2A to 2C, includes a plurality of LED light sources 110, and electrically connects to the output terminal of the rectifying unit to constitute a power loop. In this embodiment, the LED light sources are connected in parallel, in series, or in both series and parallel before connecting to the output terminal of the rectifying unit 10 to constitute a power loop. In this case, the pulsed D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com