Automatic Laundry Washer with Active Venting

a laundry machine and active technology, applied in other washing machines, lighting and heating apparatus, textiles and paper, etc., can solve the problems of lack of adequate air venting in the treatment chamber, and affecting the use of scent products. , to achieve the effect of facilitating user refilling of scent products and reducing moistur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

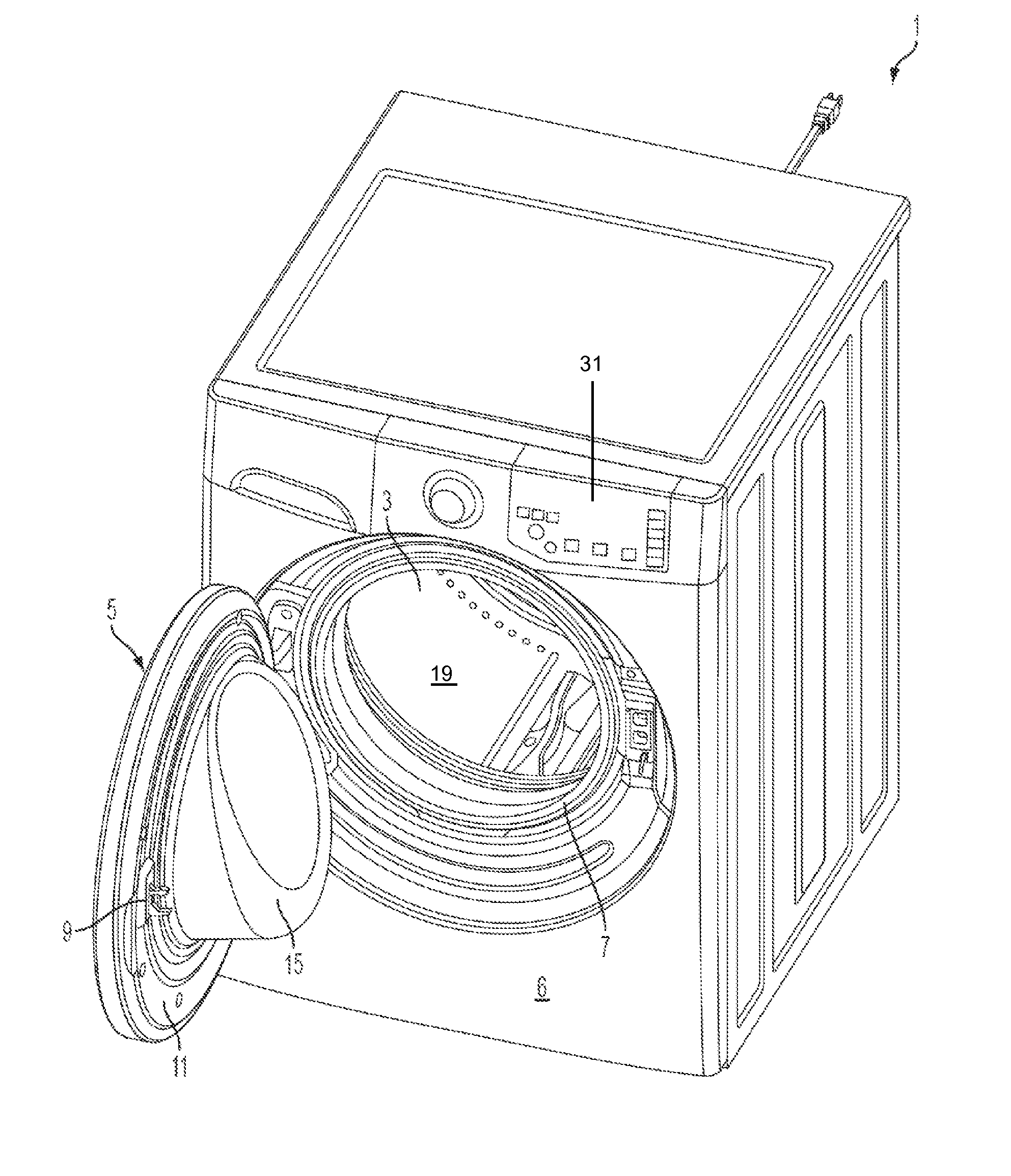

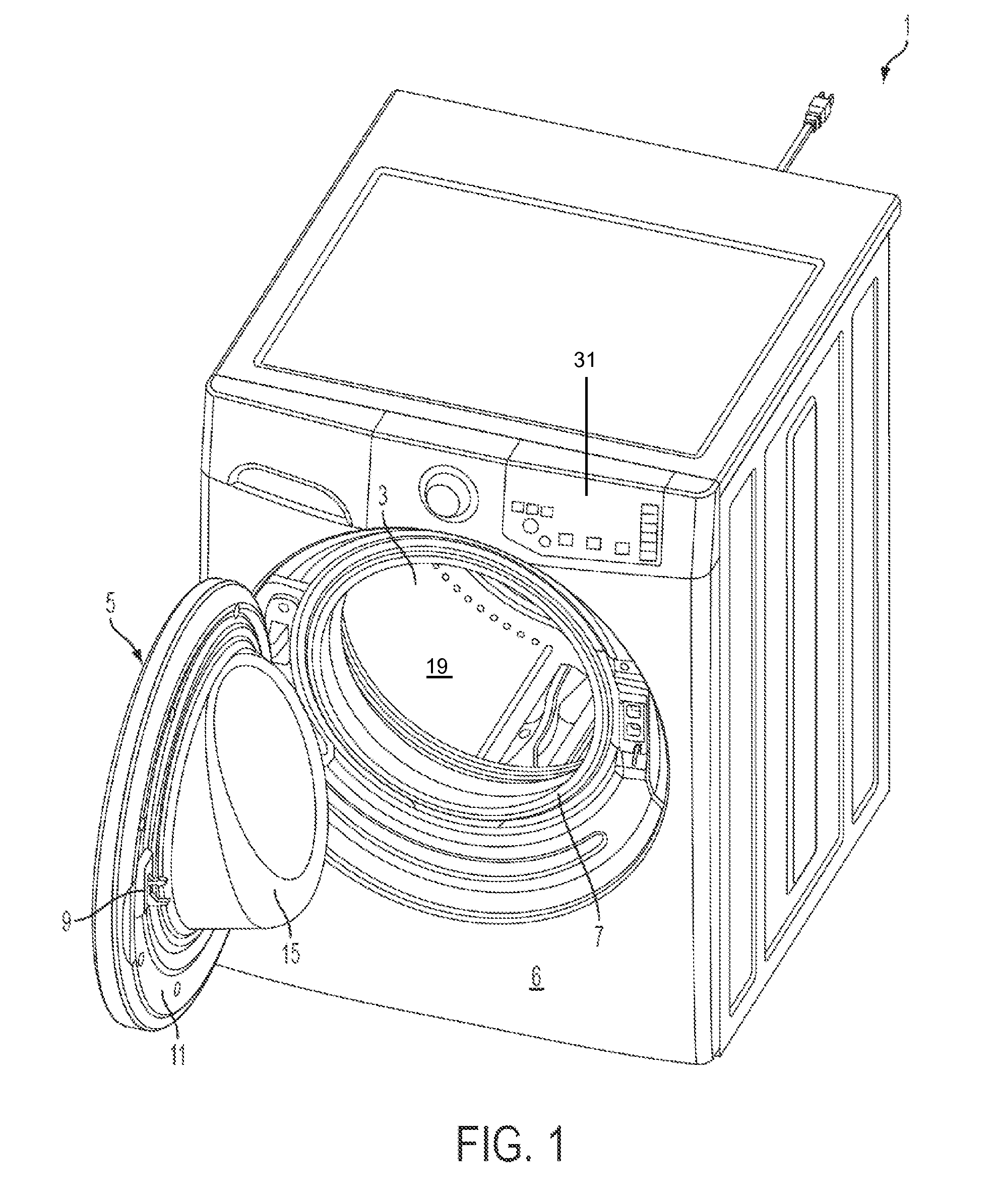

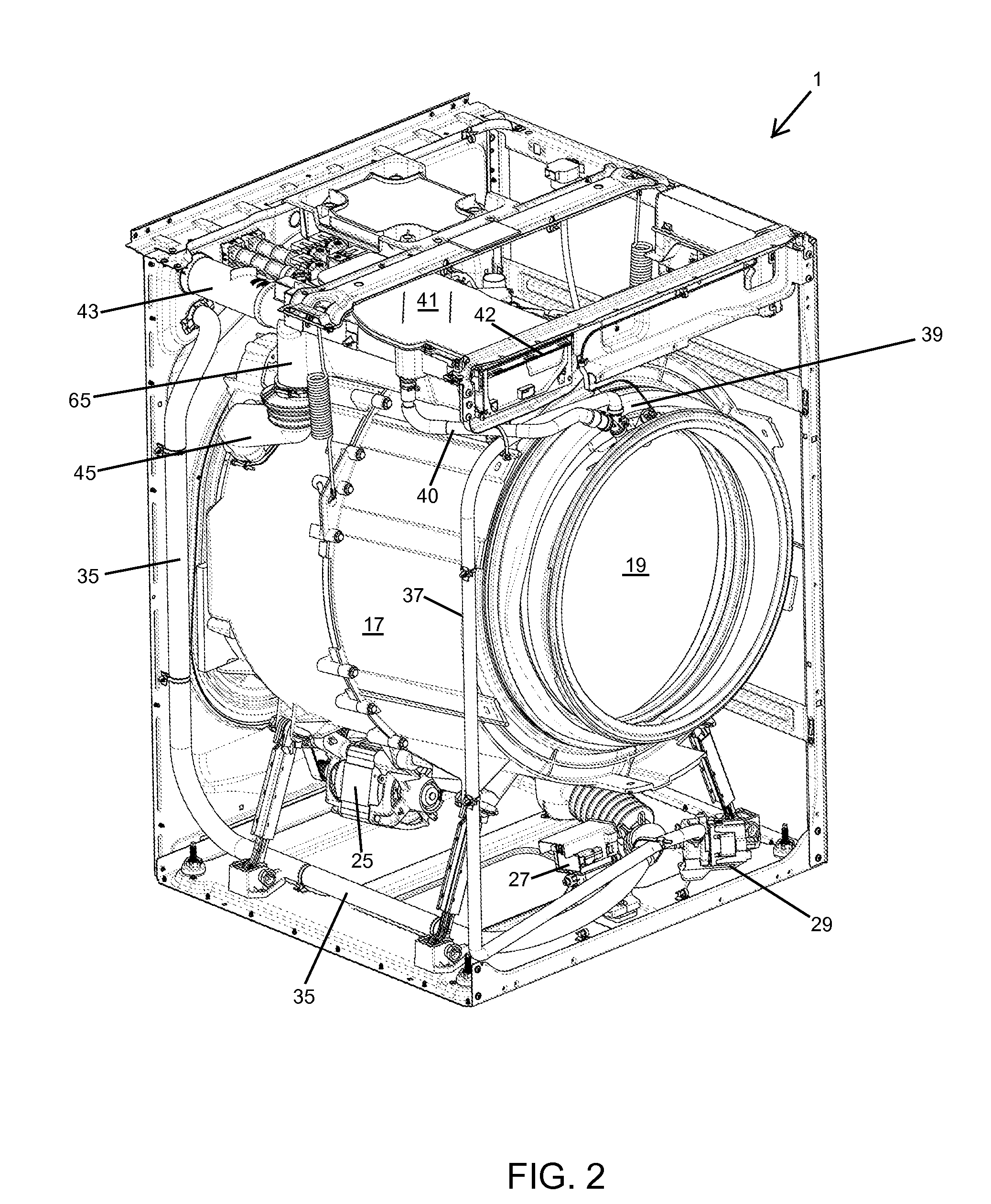

[0035]Referring first to FIG. 1, illustrated is an exemplary automatic laundry washing machine 1 of the front-load, rotating drum variety. The washing machine 1 includes a port-hole style access opening 3, and an access door 5 hingedly mounted on a cabinet front panel and / or bulkhead 6 to swing between open and closed positions.

[0036]Surrounding access opening 3 is a compressible door bellows 7 of rubber or the like that provides a water-tight flexible connecting passage extending between the access opening of the suspended wash group and the access opening 3 of the cabinet front panel 6. Bellows 7 also serves to provide a liquid-tight seal with access door 5 when the door is closed and latched. With access door 5 in the open position as shown in FIG. 1, it can be seen that a door strike structure 9 is mounted on and protruding inwardly from an inner frame 11 of the door 5. This inner frame 11 surrounds an inwardly directed port-hole plug structure 15, which may be formed of molded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com