Coupler

a technology of couplers and bearings, applied in the field of couplers, can solve the problems of coupler fatigue failure, coupler assembly, draw load, etc., and achieve the effects of increasing the bearing area, increasing the load capacity of the coupler, and increasing the bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

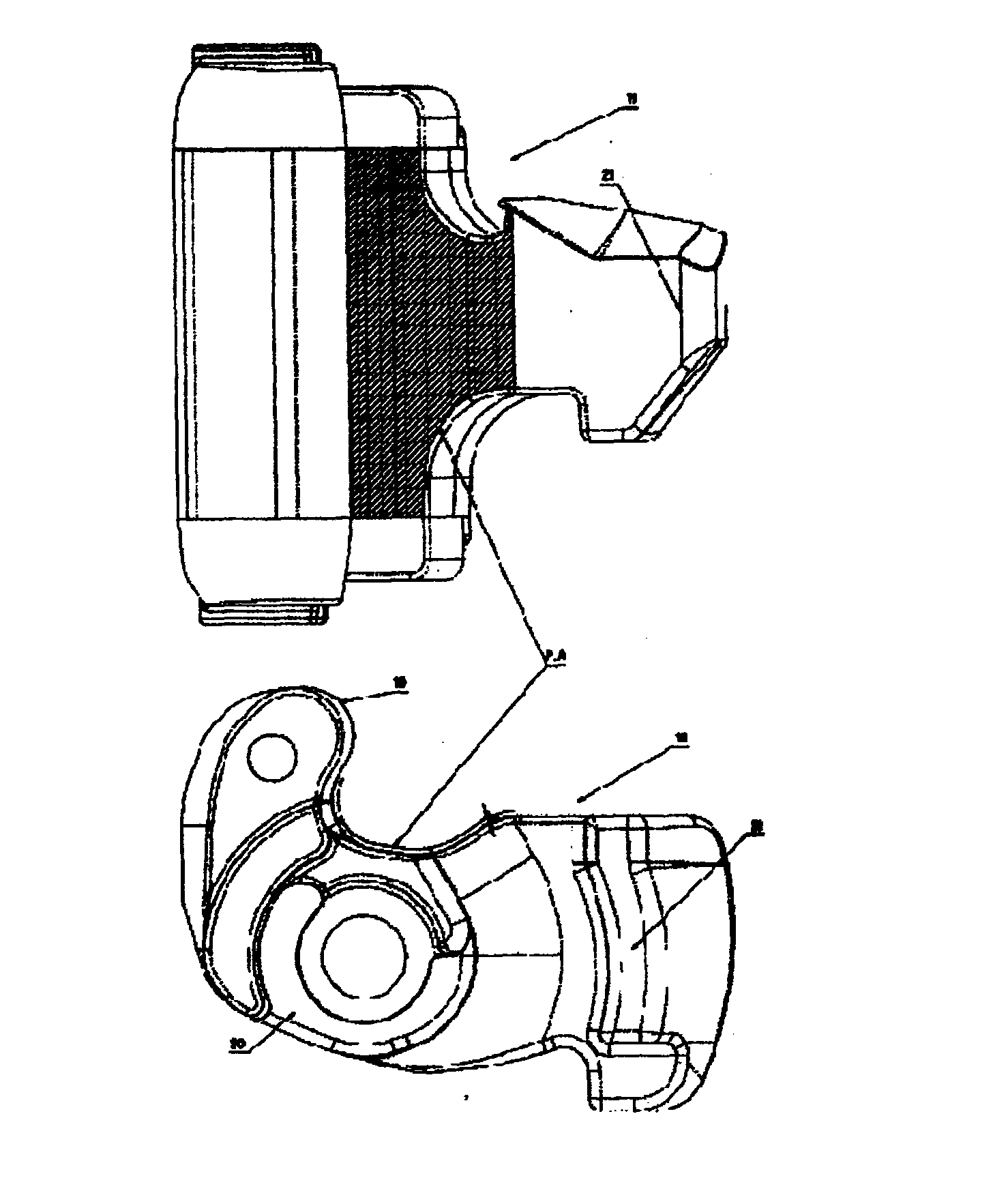

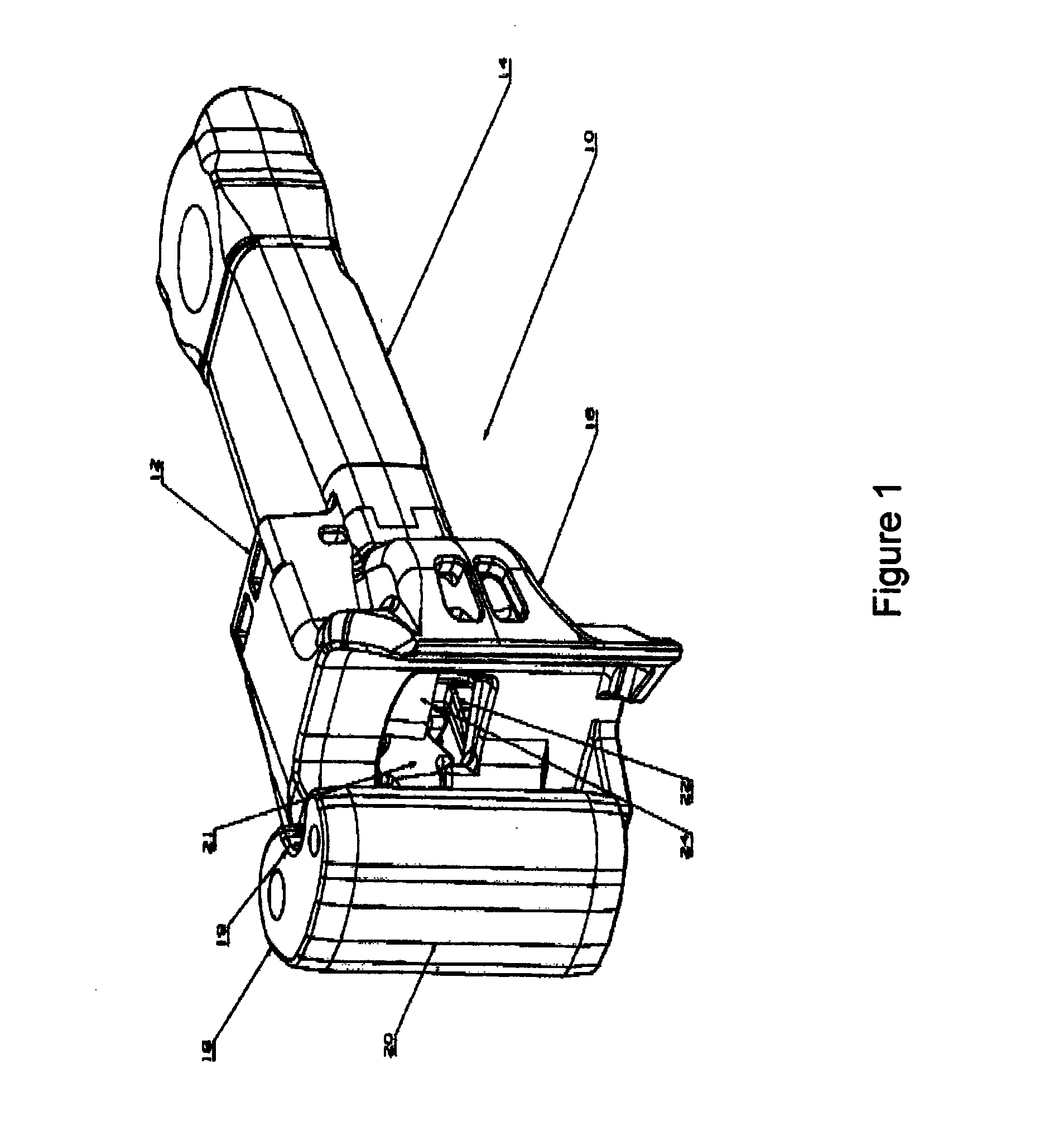

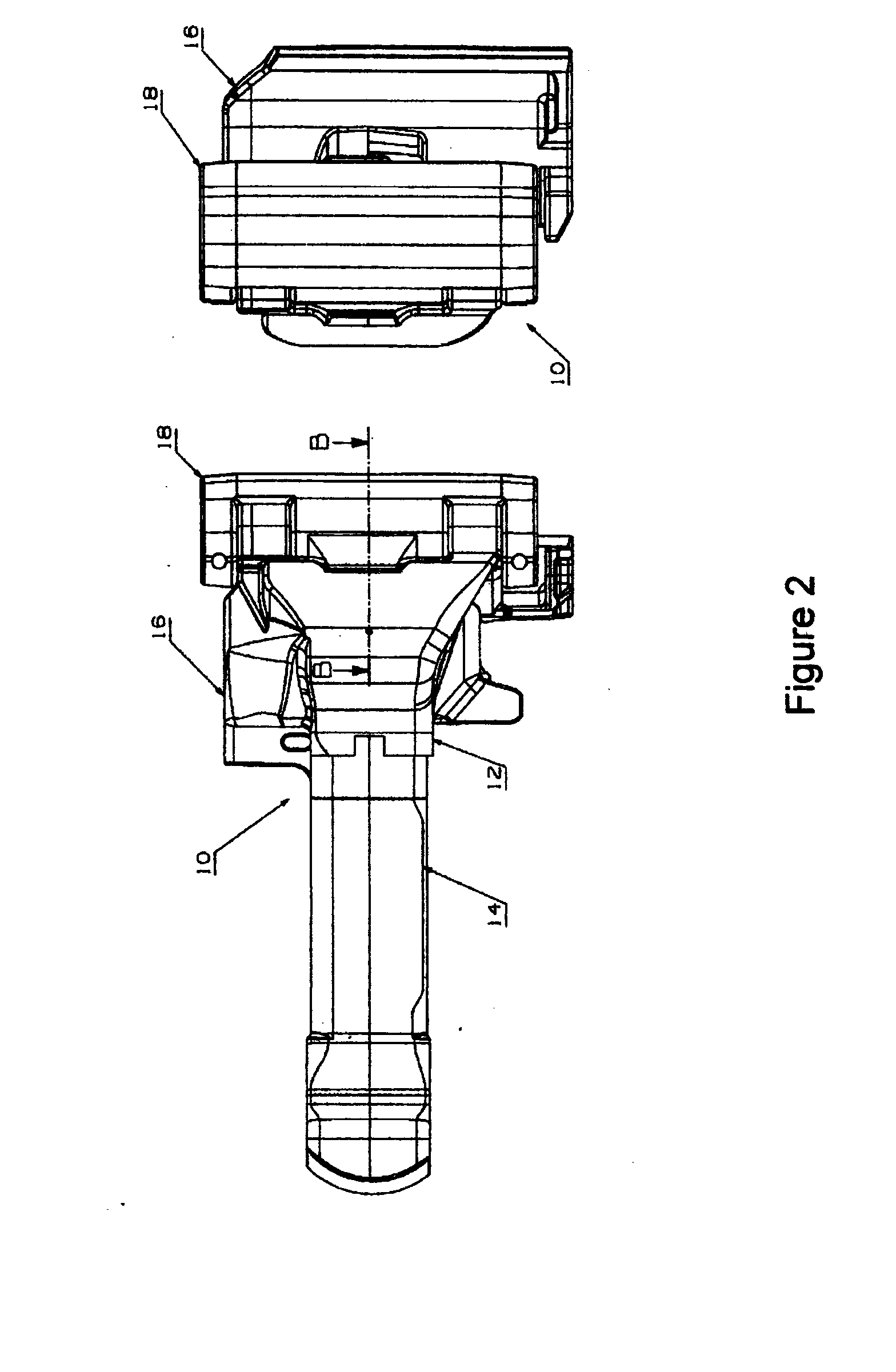

[0055]Referring firstly to FIG. 1, a rail wagon coupler 10 includes a coupler body 12 cast as a single unit from alloyed steel. The body 12 comprises a shank 14 and an integral head 16 located at an end of the shank 14. A coupler latch member in the form of a knuckle 18 is pivotally mounted to an end of the head 16. The knuckle 18 comprises a latching portion 19 extending from an elongate knuckle body 20 that pivots on the head about an elongate axis. The knuckle is also cast as a single unit from alloyed steel, though the grade may vary (e.g. be improved) from that employed for the coupler body.

[0056]Coupler 10 is an automatic-type coupler, in that it automatically latches (i.e. via latching portion 19) with an opposing like-coupler when two rail wagons are buffed together. The coupler functions to join the two wagons and in use transmits both buff (compressive) and draw (tensile) loads between the wagons. The draw loads are the main loads responsible for fatigue failures in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com