Heat Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

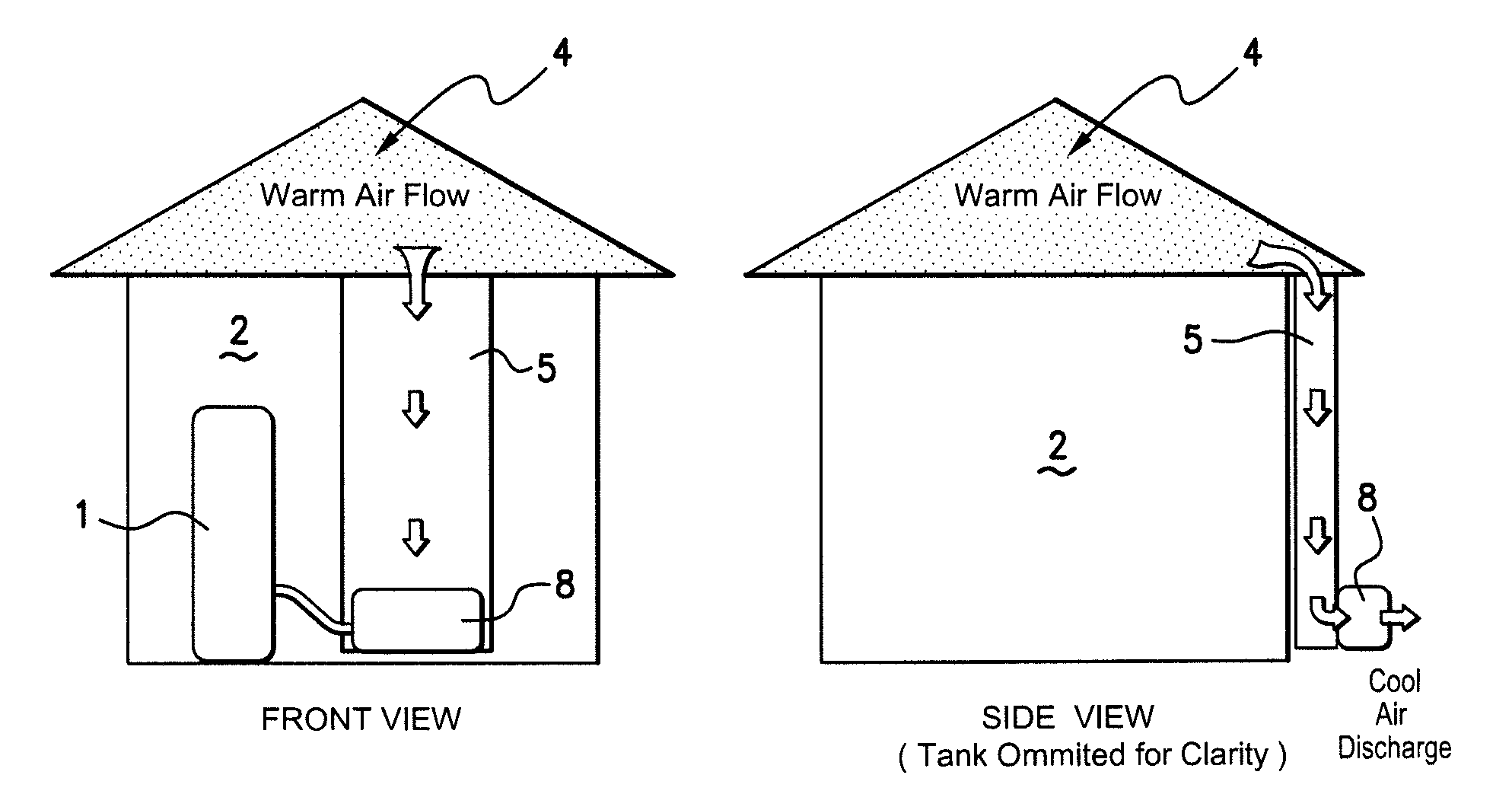

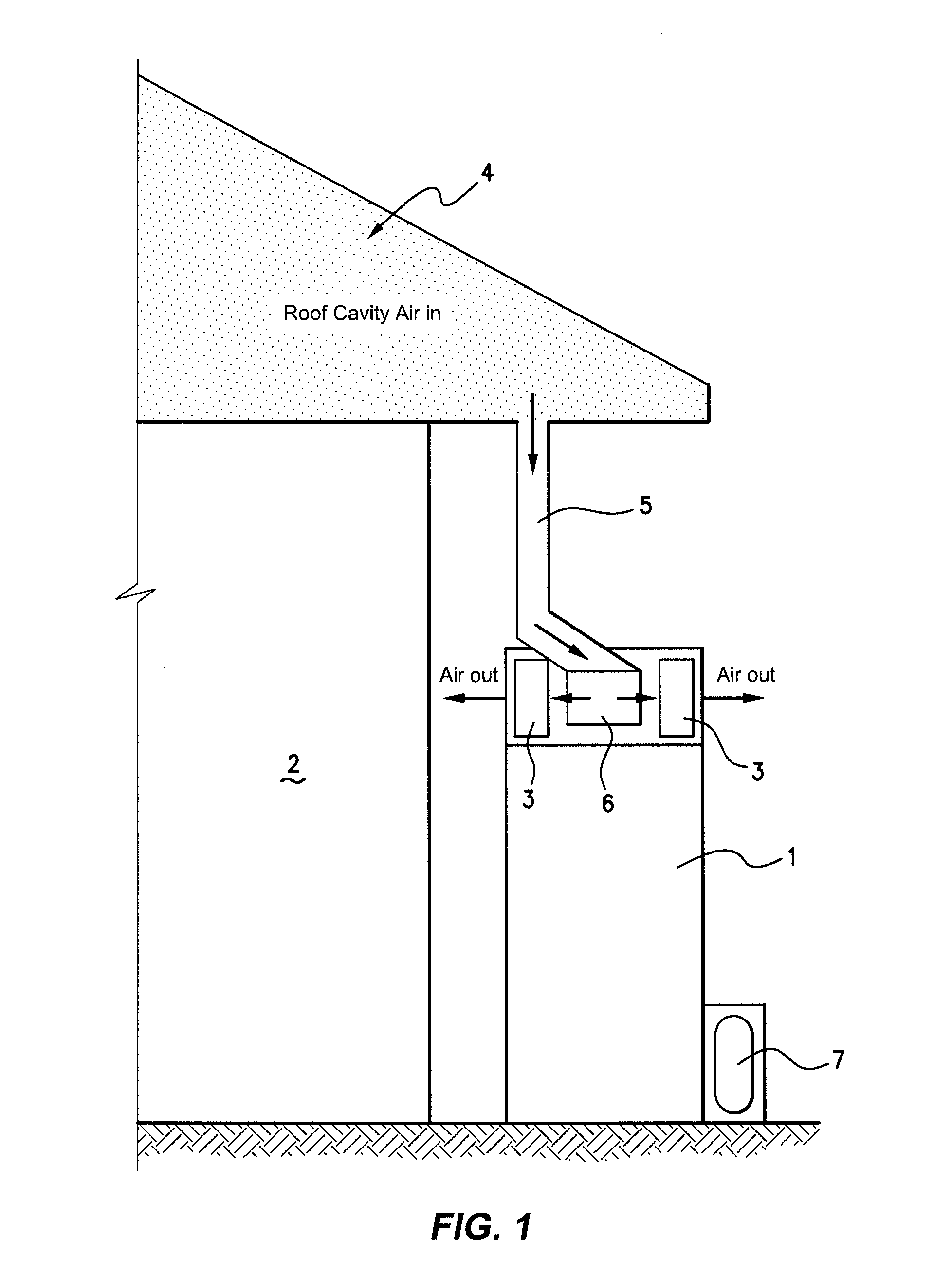

[0067]Referring firstly to FIG. 1, a particularly preferred embodiment of the invention is shown in schematic form in the form of a heat pump system particularly adapted for heating domestic hot water, utilising the heat from the roof cavity of a domestic dwelling.

[0068]The heat pump system includes a primary water reservoir tank 1, which functions as a heat sink. The water tank is configured for placement on the ground proximate to the dwelling 2. The heat pump system is specifically configured to a place all the lightweight elements and components toward the top of the tank 1 and the heavier components towards the bottom of the tank 1 in order to maximise stability and ease of fitting to the dwelling 2. The evaporator or evaporators 3 constitute one of the lighter weight components of the system and are conveniently placed on top of the tank and are adapted to receive air flow from the roof cavity 4, which provides air that is heated by virtue of the relationship to the dwelling 2...

example two

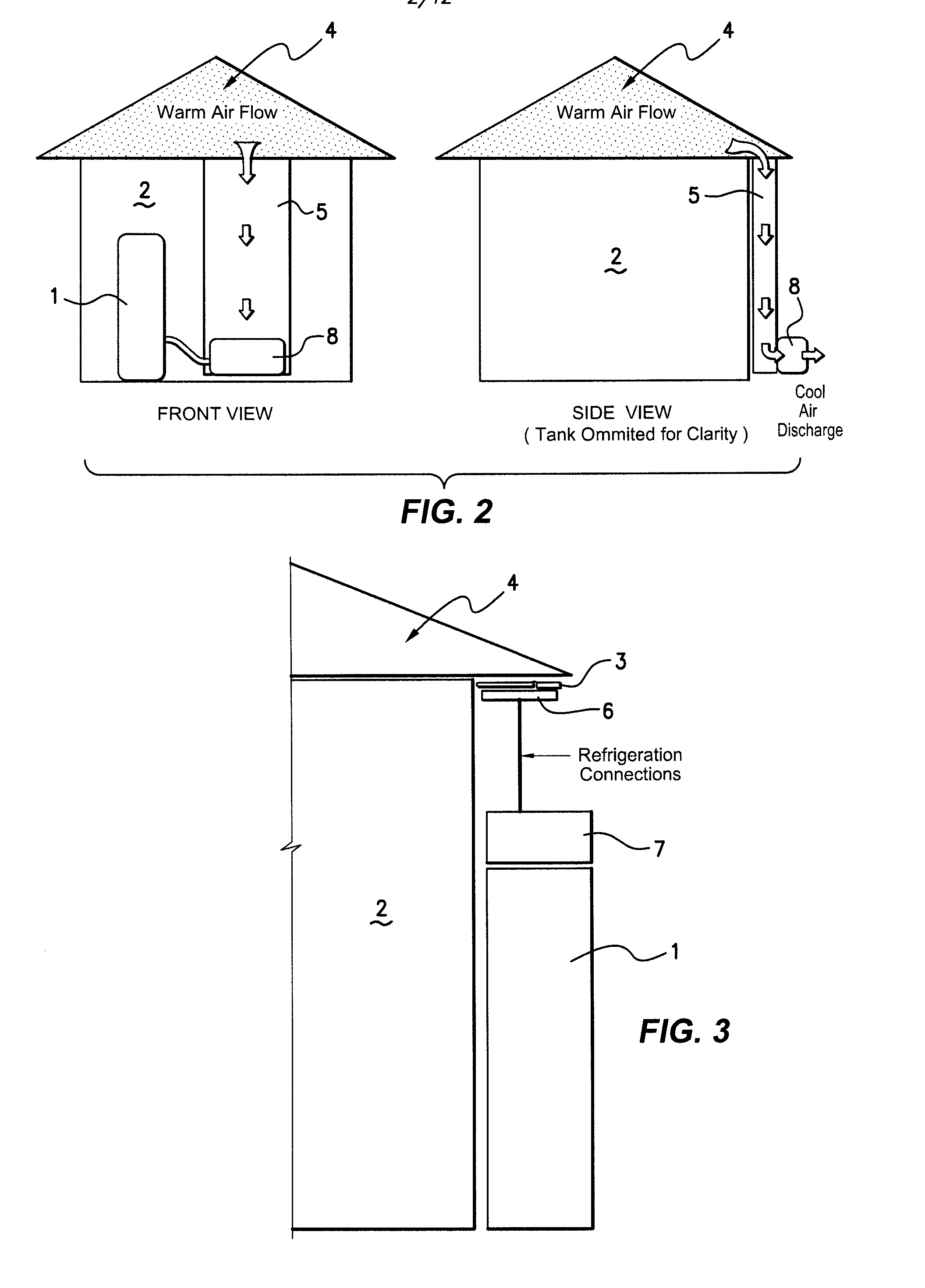

[0104]Referring now to FIG. 3, another embodiment of the invention, includes the physical separation of the heat pump 8 by separation of the compressor 7 and evaporator 3, thereby allowing ready positioning of the evaporator close to the preferred heat source, whilst involving minimal disruption to conventional building and installation procedures.

[0105]Whilst the previous examples exhibit substantial merit over prior art known, two disadvantages may occur in certain circumstances. For example, it can be difficult to install the heat pump embodiment as shown in FIG. 2, to a single story house without eaves or alternatively, to a multi-story building. In another example, such installations as shown in FIG. 2 may be regarded as aesthetically undesirable, due to the ducting required for retro-fitting to the side of the dwelling in question.

[0106]In order to address these issues, the invention as previously described has been modified with the provision of the heat pump into the roof sp...

example three

[0111]In another example of the invention the hardware of a conventional heat pump driven hot water system is used where the evaporator is mounted remotely from the tank inside the roof cavity of a home. In this example there is no ducting applied to the evaporator—which sits inside the roof cavity. The smart controller is programmed to operate the system when the roof cavity is warmest which dramatically improves the efficiency of the heat pump compared to a situation where the evaporator is outside on the ground.

[0112]Multiple (e.g. 2 or 3) temperature sensors are installed inside the water tank to allow the smart controller to monitor how much hot water has been used. These sensors will sense the amount of hot water remaining in the tank (high, low and very low). If hot water is used during the day and the amount of hot water drops below the “high” level then the smart controller will automatically start the heat pump and ensure the tank is completely full of hot water by the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com