Apparatus and process for generation of energy by organic rankine cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

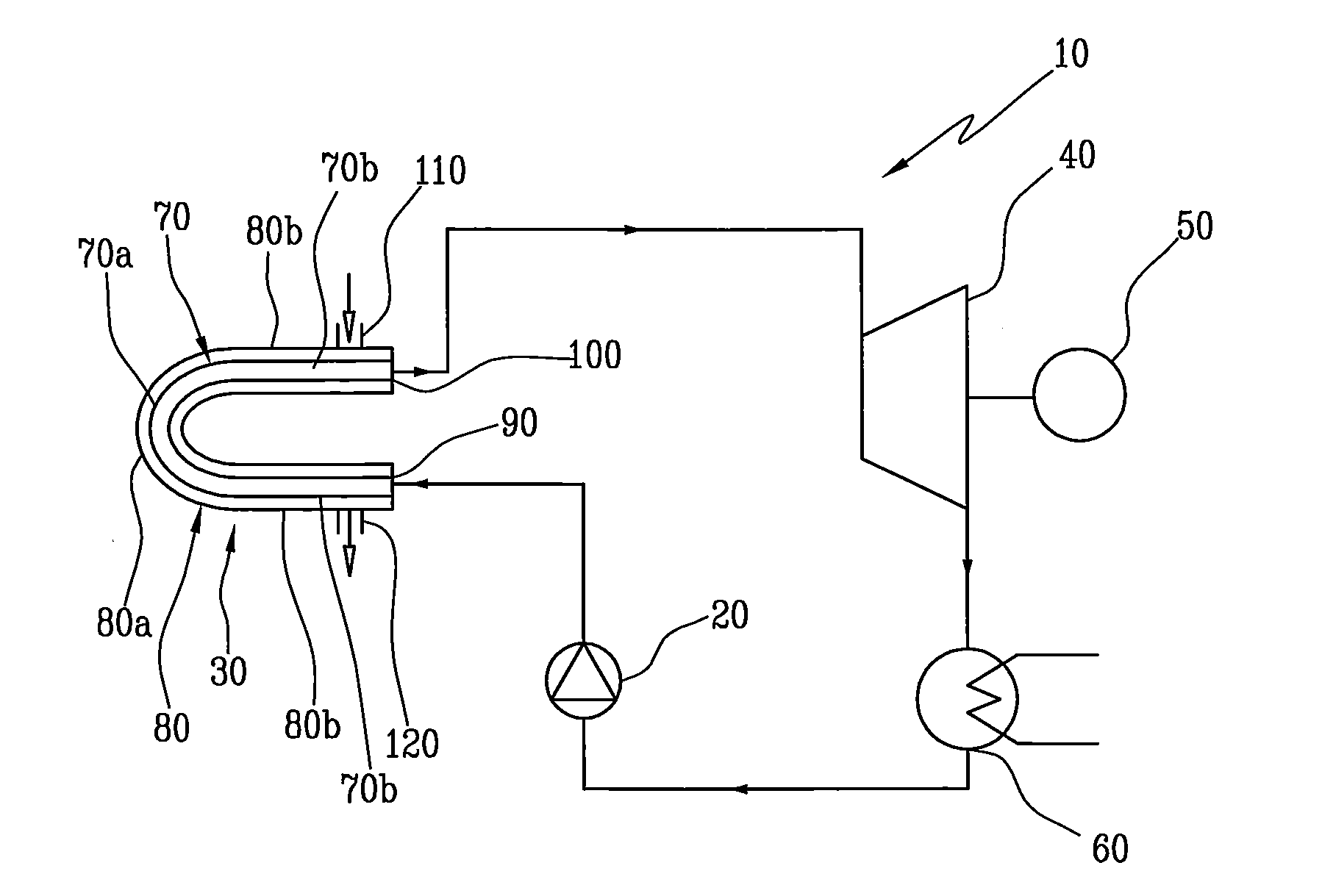

[0034]With reference to the mentioned figures, generally denoted at 10 is an apparatus for energy generation through the organic Rankine cycle (ORC) according to the present invention.

[0035]Apparatus 10 comprises an endless circuit in which an organic working fluid flows which has a high or medium molecular weight. This fluid can preferably be selected from the group comprising hydrocarbons, fluorocarbons and siloxanes.

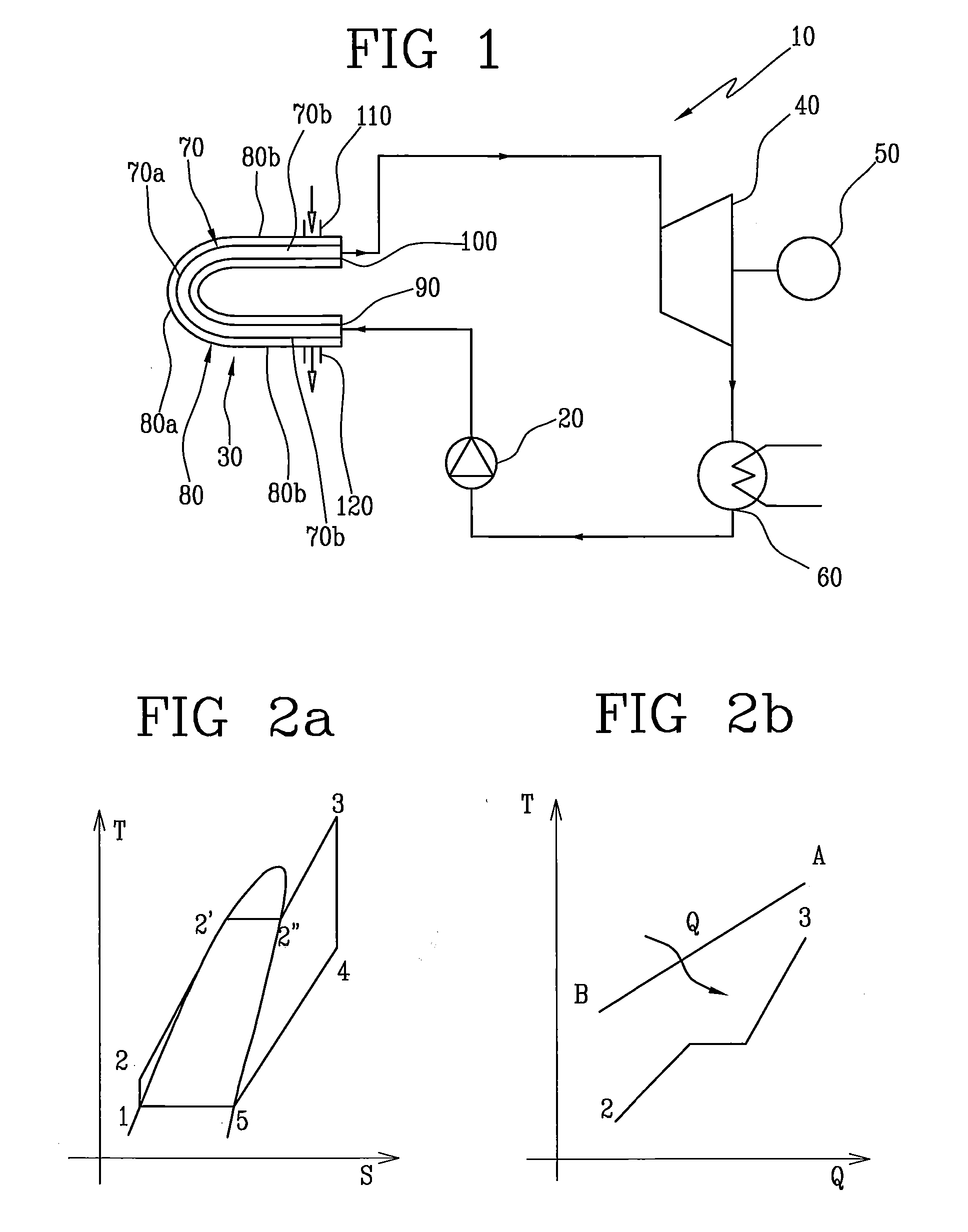

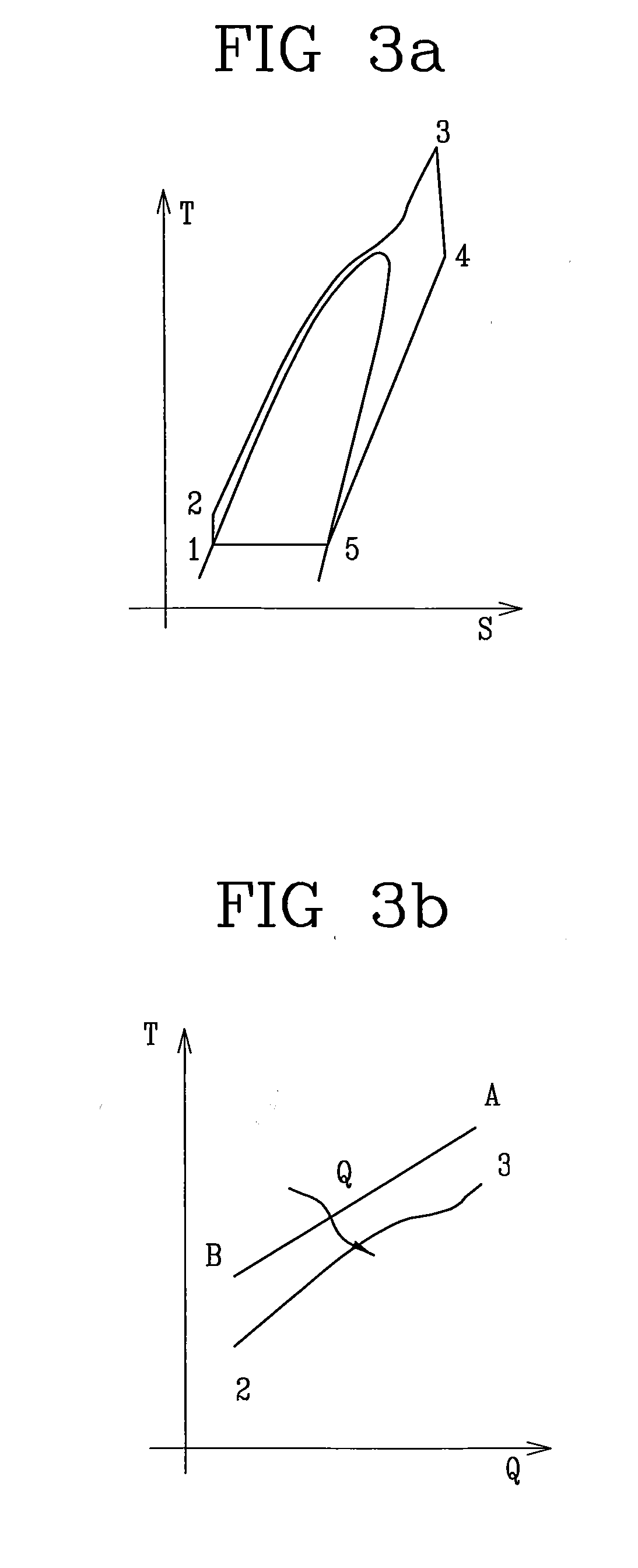

[0036]FIG. 1 shows the circuit of the Rankine cycle in its base configuration and contemplates: a pump 20, a heat exchanger 30, a turbine 40 connected to an electric generator 50, a condenser 60.

[0037]Pump 20 admits the organic working fluid from condenser 60 into the heat exchanger 30. In the heat exchanger 30 the fluid is heated, evaporated and then fed in the vapour phase to turbine 40, where conversion of the thermal energy present in the working fluid into mechanical energy and then into electrical energy through generator 50 is carried out. Downstream of turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com