Energy-Harvesting Reactor Based on Diffusion of Aluminum in Gallium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

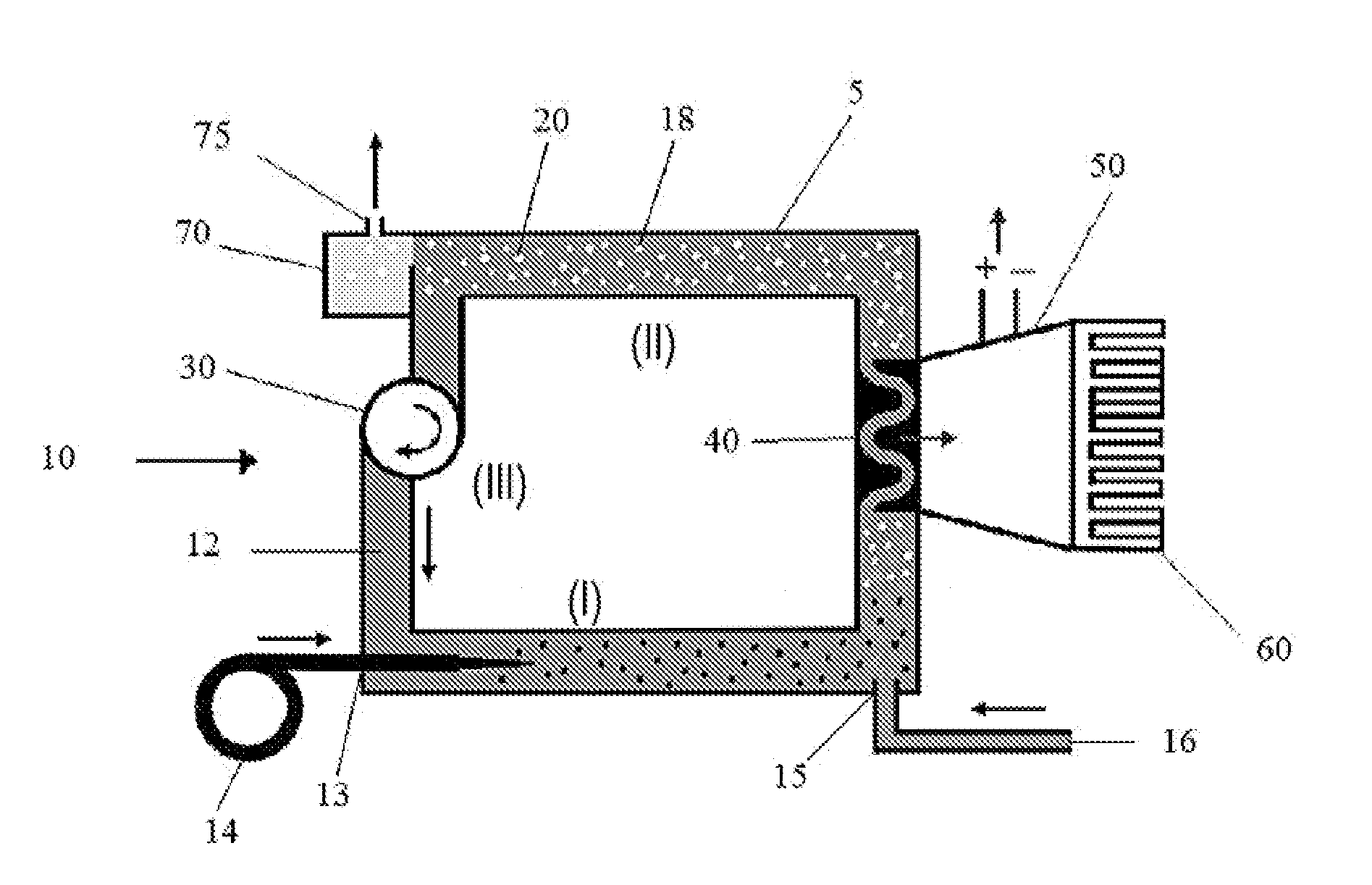

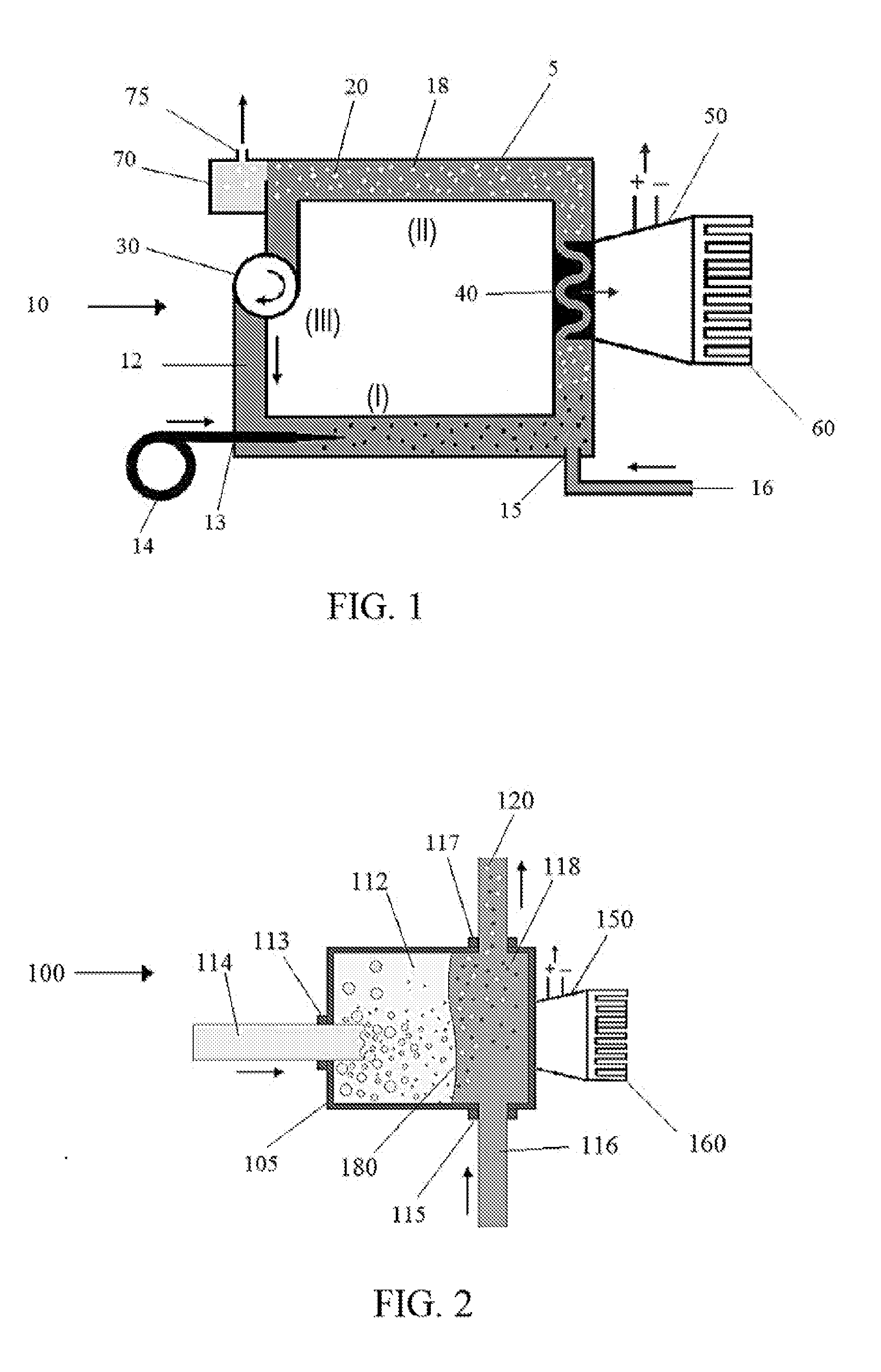

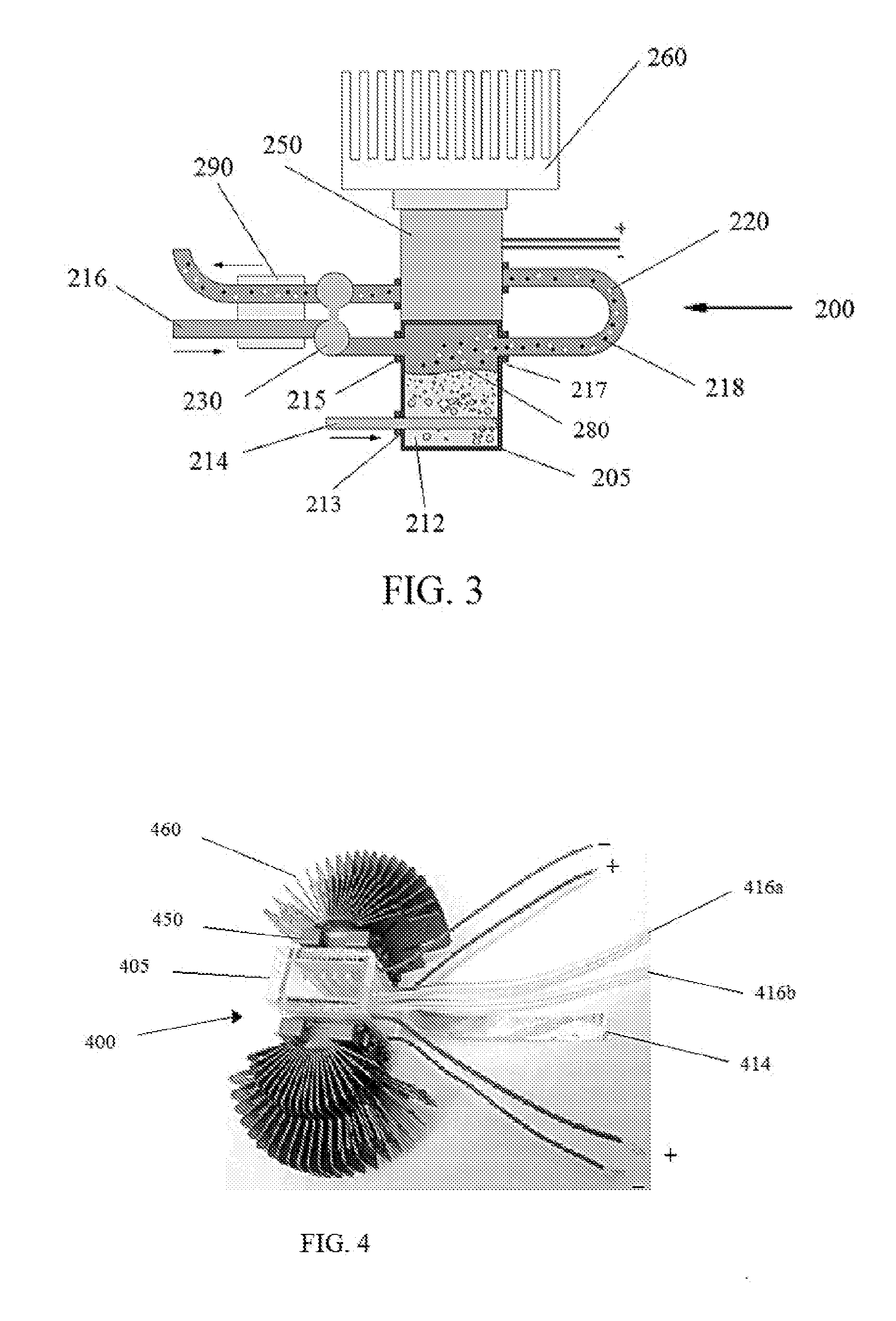

[0009]There are now described systems and methods for their use for the production of high thermal energy which may be harvested as a substantial anaerobic energy source for powering vehicles such as unmanned-underwater vehicles (UUVs) or unmanned aerial vehicles (UAVs), other small robotics, backup or regular underwater power sources (e.g., for oil rigs), or as an emergency power source in flooded or disaster areas.

[0010]In some embodiments, the systems rely on the use of a stream of molten depassivating agent flowing through a circuit, and passing through a source of fuel, then a source of an oxidizing agent, such as water, in small amounts with respect to the depassivating agent such that the thermodynamic properties of the depassivating agent regulate the thermal energy produced. The stream is then passed through a heat harvester and a waste purifier before being cycled back. Optionally, the hydrogen also produced in this system may be used as an additional fuel for power genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com