Wood golf club head

a golf club head and wood technology, applied in the field of golf club heads, can solve the problems of difficult to form one piece wood golf club heads, poor bonding of welding intervals, and conventional wood golf club heads that cannot perform clear and pleasing striking sound while striking, and achieve the effect of improving the forming process of weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

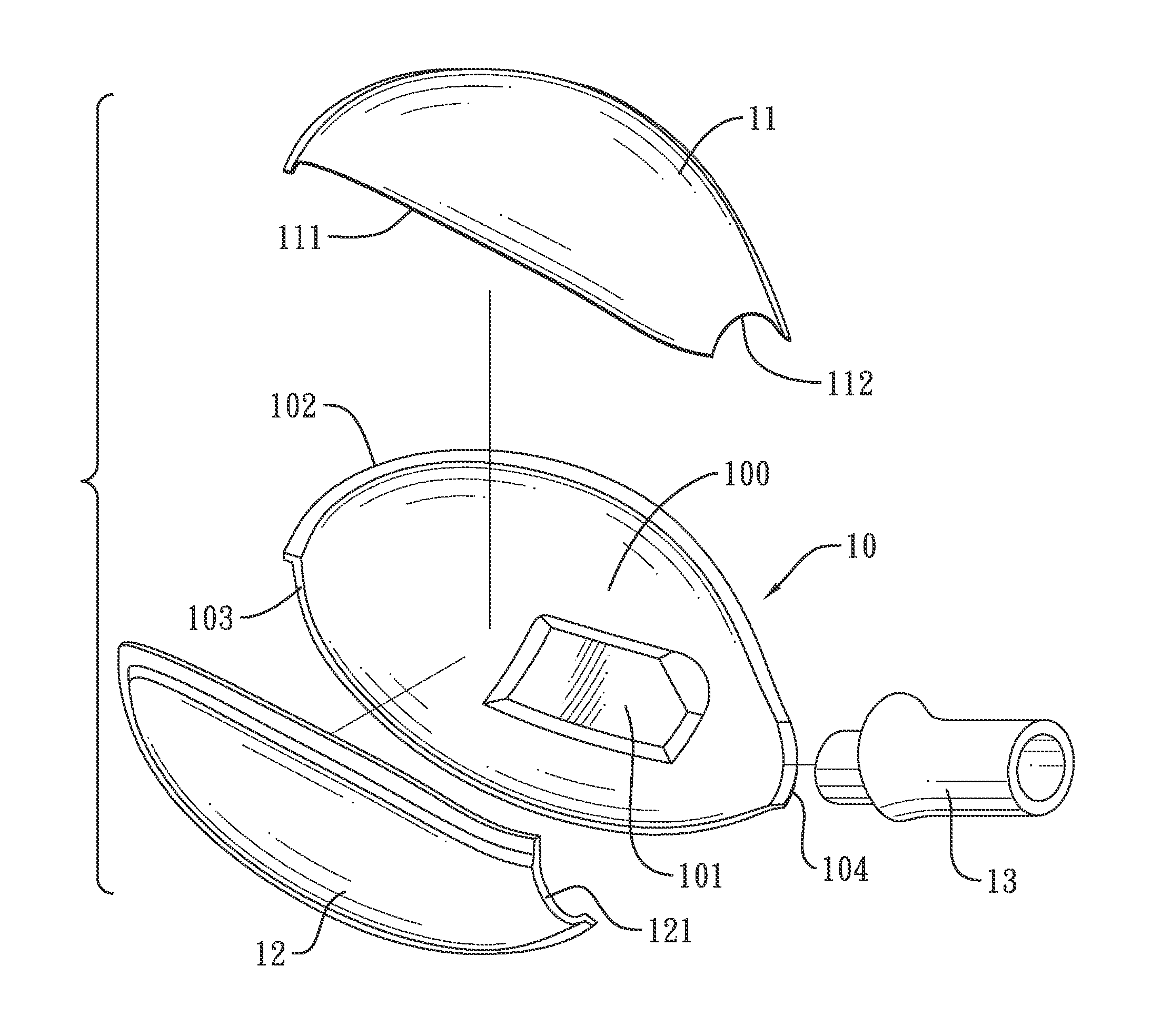

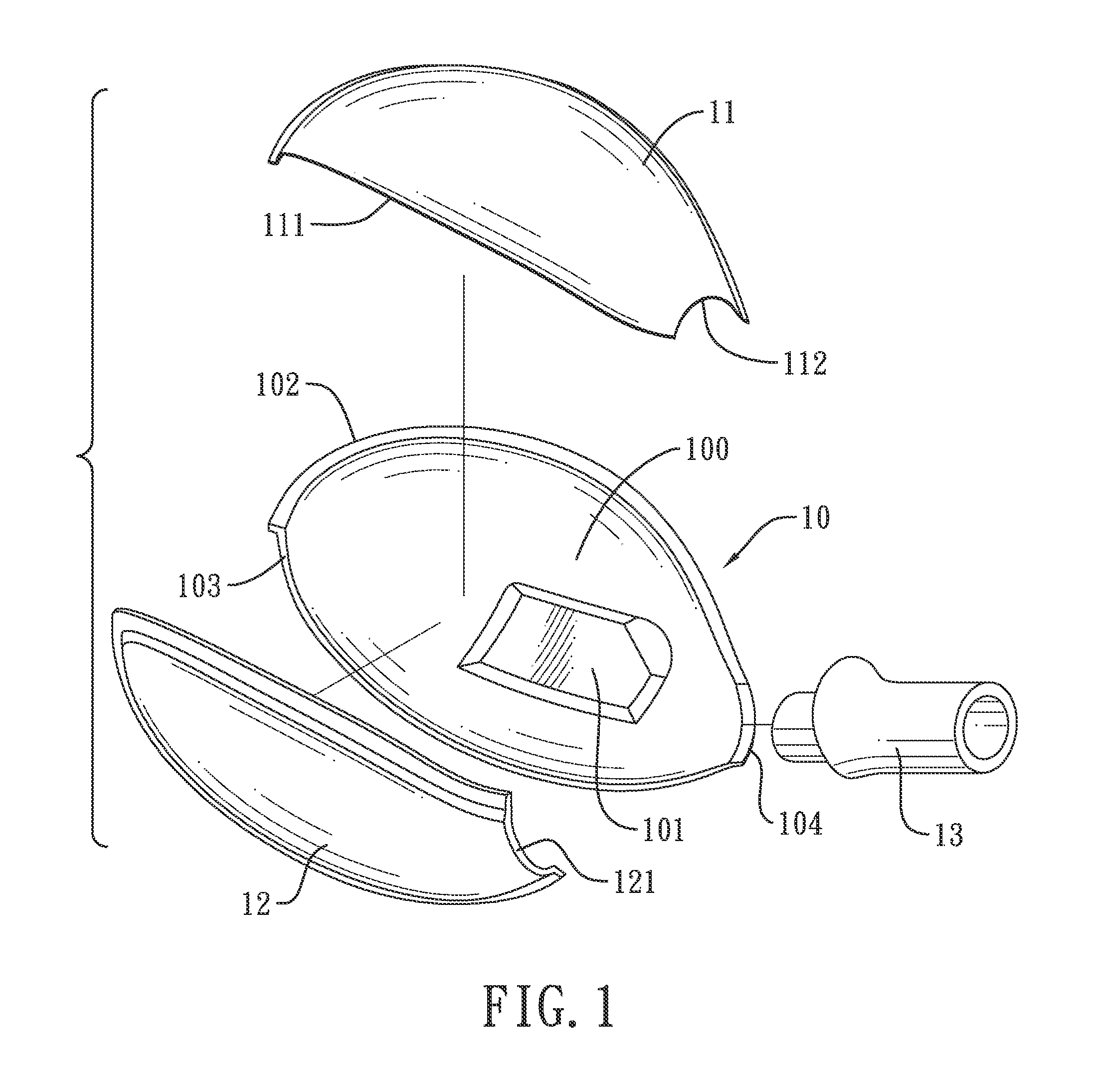

[0016]With reference to FIG. 1, a wood golf club head in accordance with the present invention is used for a wood golf club, which may be a drive, a fairway wood, or a hybrid and so on. The wood golf club head in accordance with the present invention comprises a sole plate 10, a crown 11, a strike face 12 and a hosel 13.

[0017]The sole plate 10, the crown 11, the strike face 12 and the hosel 13 are made of metal, which may be selected from titanium, stainless steel, carbon steel, aluminum alloy and so on. The sole plate 10, the crown 11, the strike face 12 and the hosel 13 may be made of the same metal or may be made of two different metals.

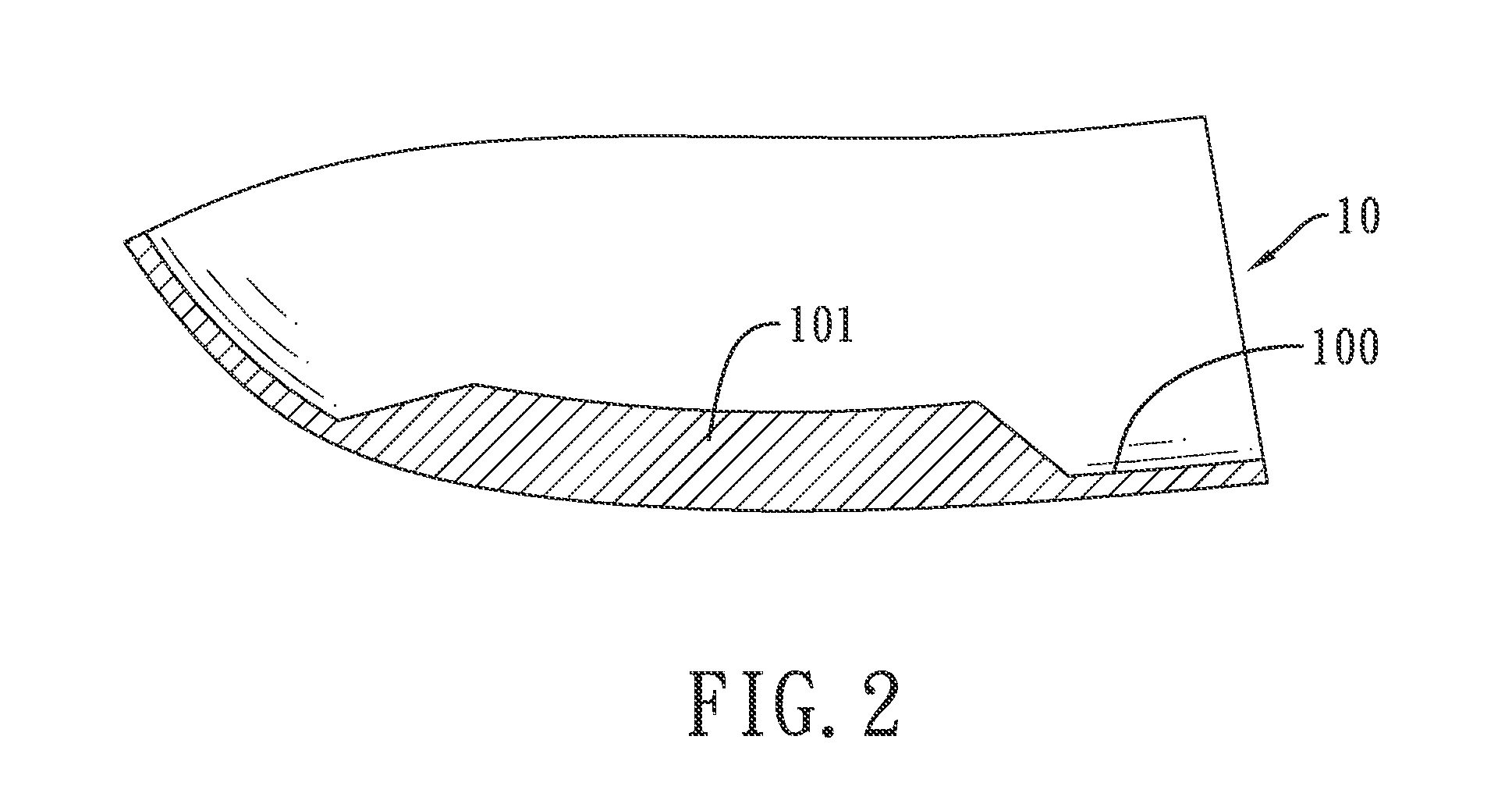

[0018]With reference to FIGS. 1 and 2, the sole plate 10 is made of a slab of a bar by hot forging to have different thicknesses at different parts. A weight 101 is formed as a thicker part of the sole plate 10. Other parts of the sole plate 10 may have uniform thicknesses or may have a uniform thickness, which depends on the designed shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com