Paper-made composite furniture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

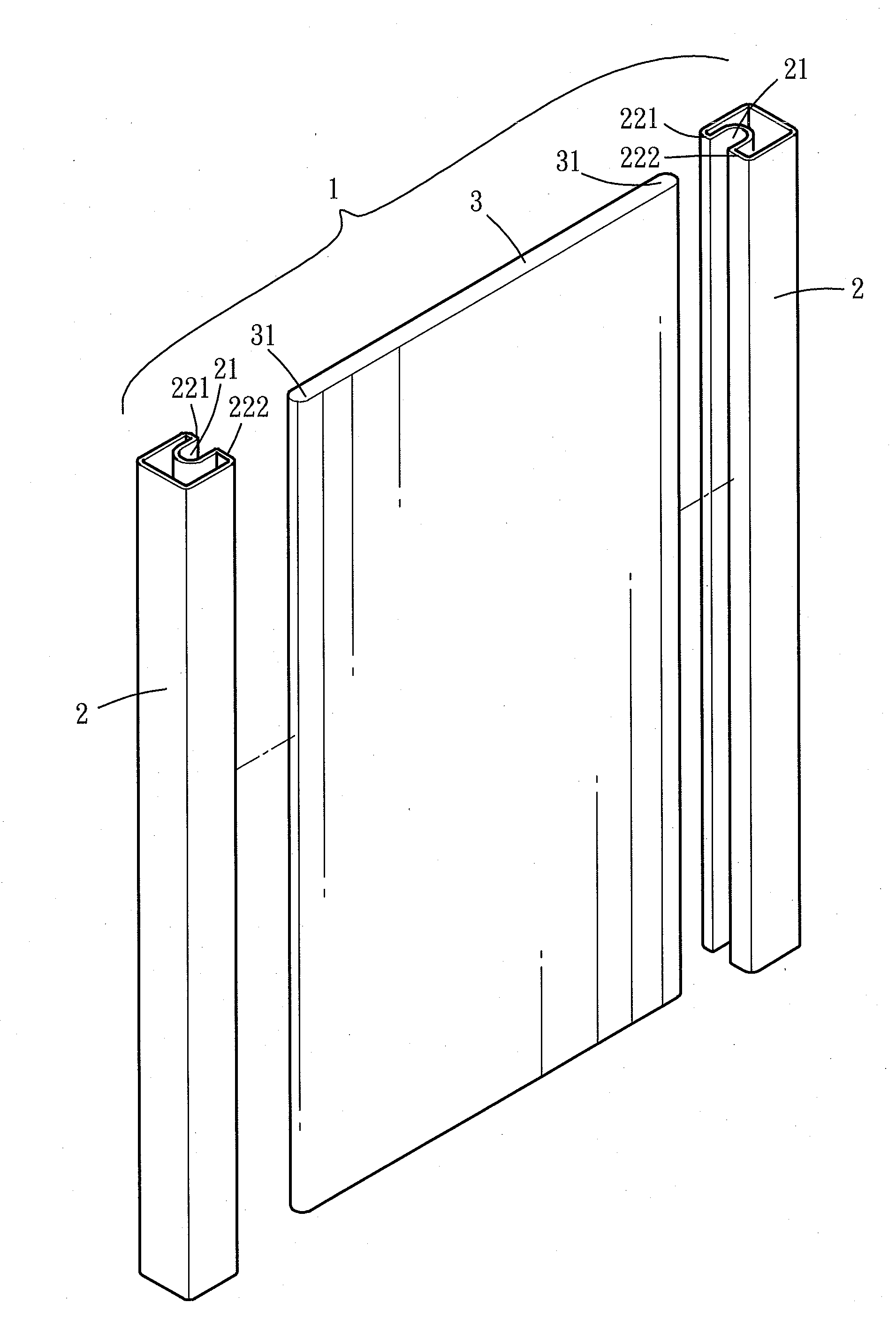

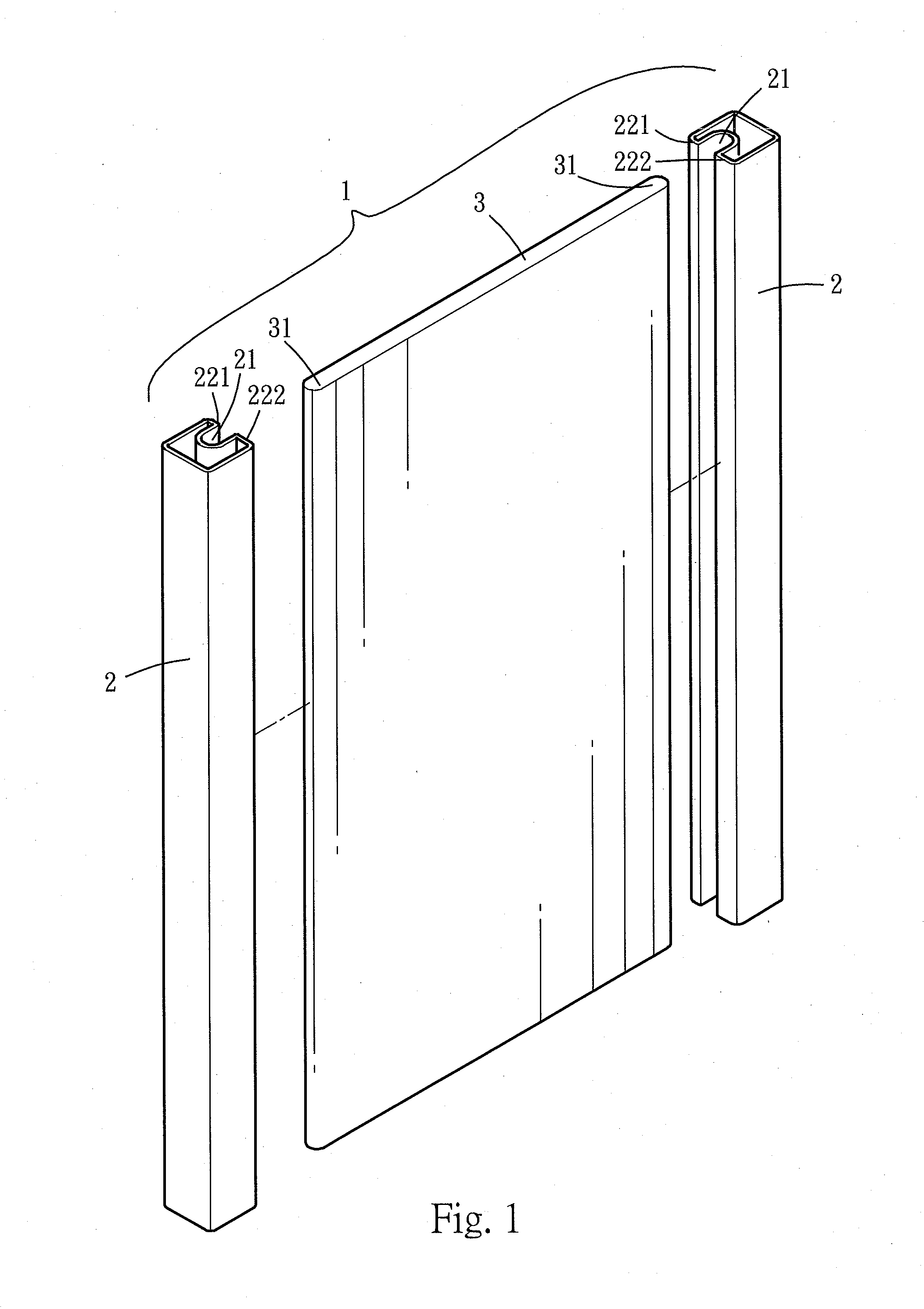

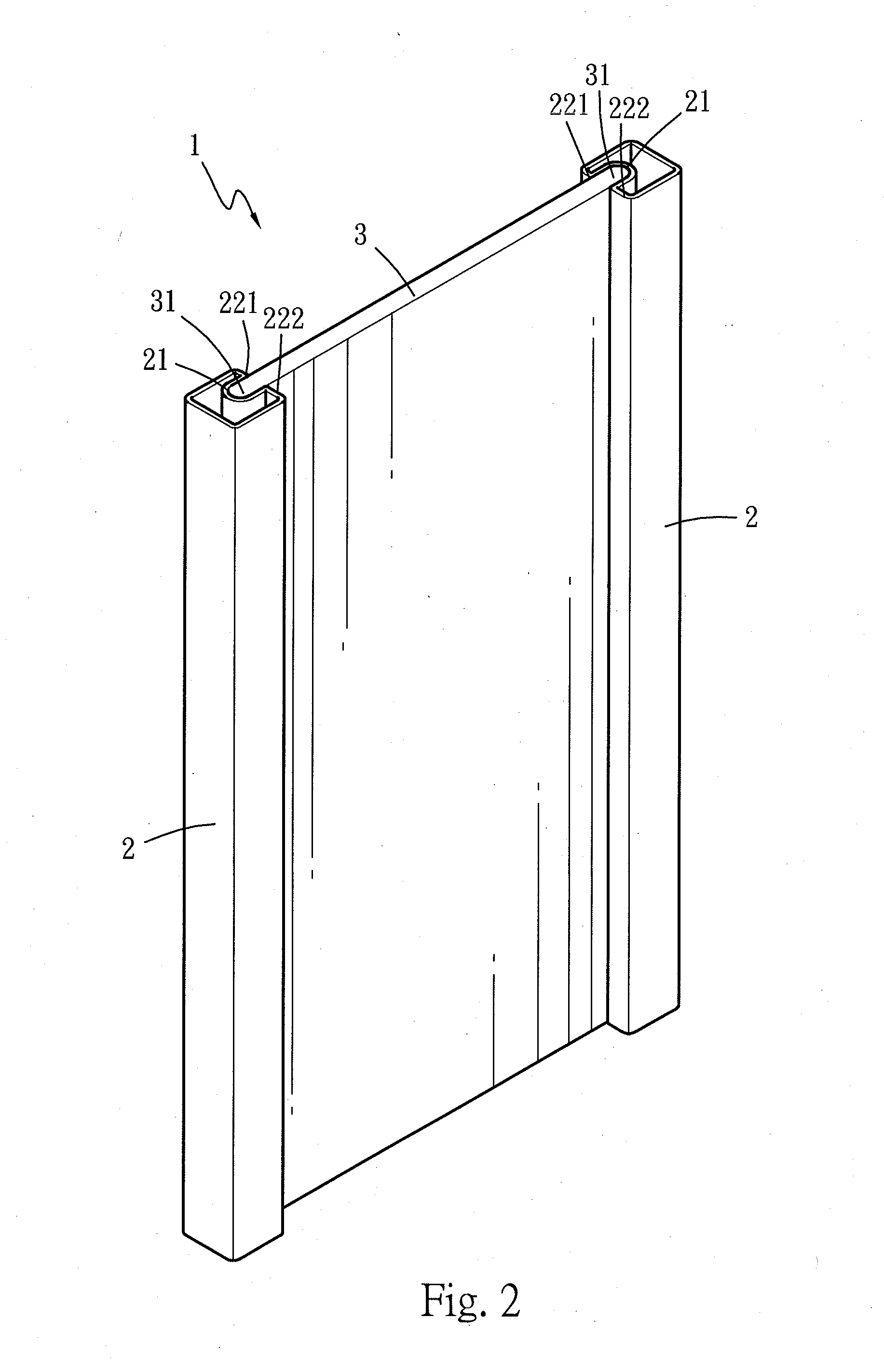

[0022]Please refer to FIGS. 1 and 2, the paper-made composite furniture of the invention comprises at least two connection tubes 2 and at least one spacer 3. Each connection tube 2 is a hollow tube with an inner side made of stiff paper and an outer side made of smooth paper. Each connection tube 2 has at least one latch groove 21, and a first extension section 221 and a second extension section 222 at two sides of the latch groove 21. The first extension section 221 is formed at a width smaller than that of the second extension section 222. The spacer 3 is a solid panel made of stiff paper coated by smooth paper on the outer side thereof. The spacer 3 has two sides 31 wedged respectively in the corresponding grooves 21 of the connection tubes 2 to form secure latching.

[0023]The stiff paper can be a sand tube paper. The smooth paper can be a kraft paper. The connection tubes 2 and spacer 3 can be respectively formed by compression of multi-layer stiff paper and multi-layer smooth pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap