Die cast component and a method for producing a die cast component

a technology of die casting and components, applied in the field of die casting components, can solve the problems of increased complexity, cost, and increase, and achieve the effect of high quality and easy and inexpensive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

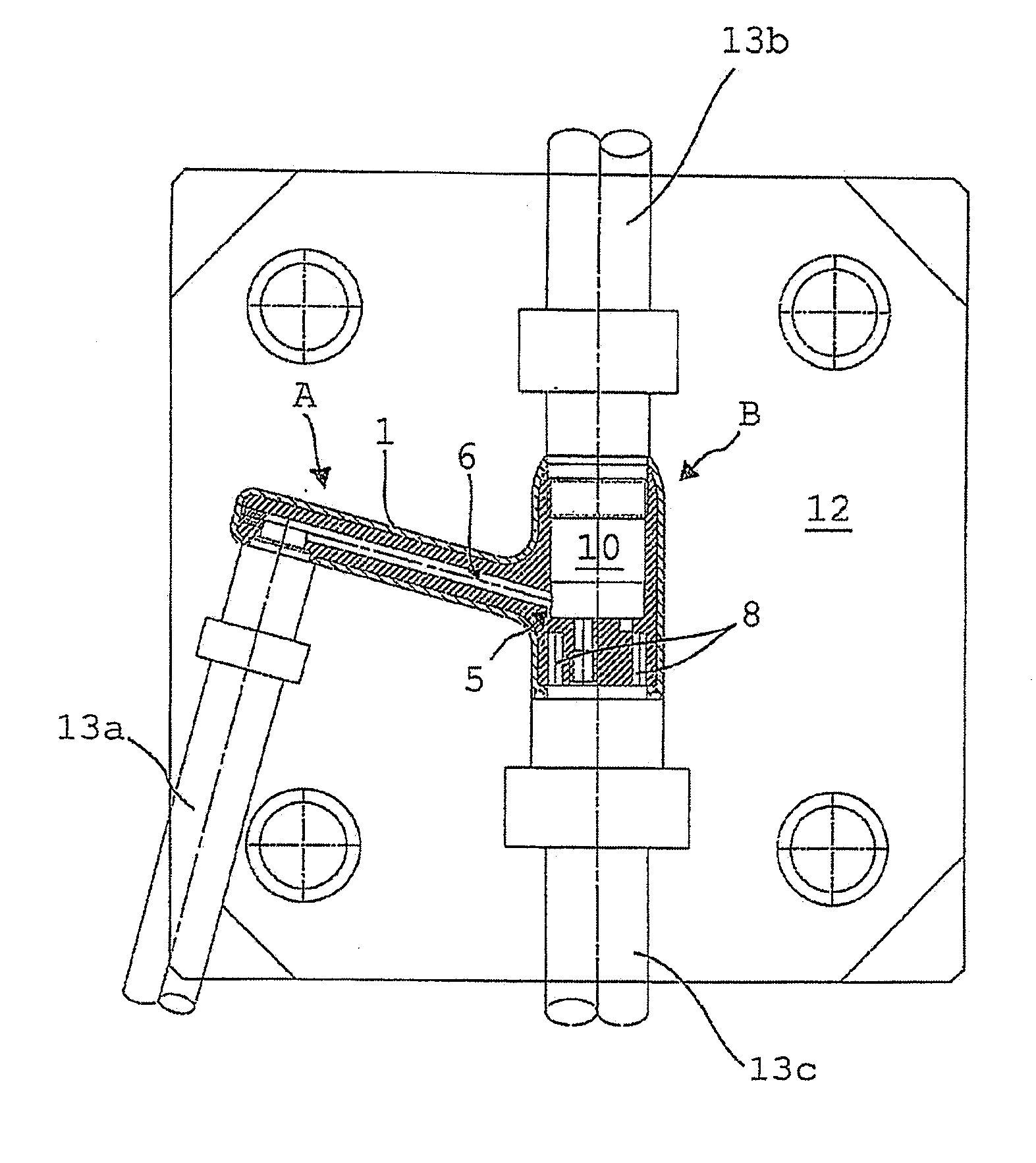

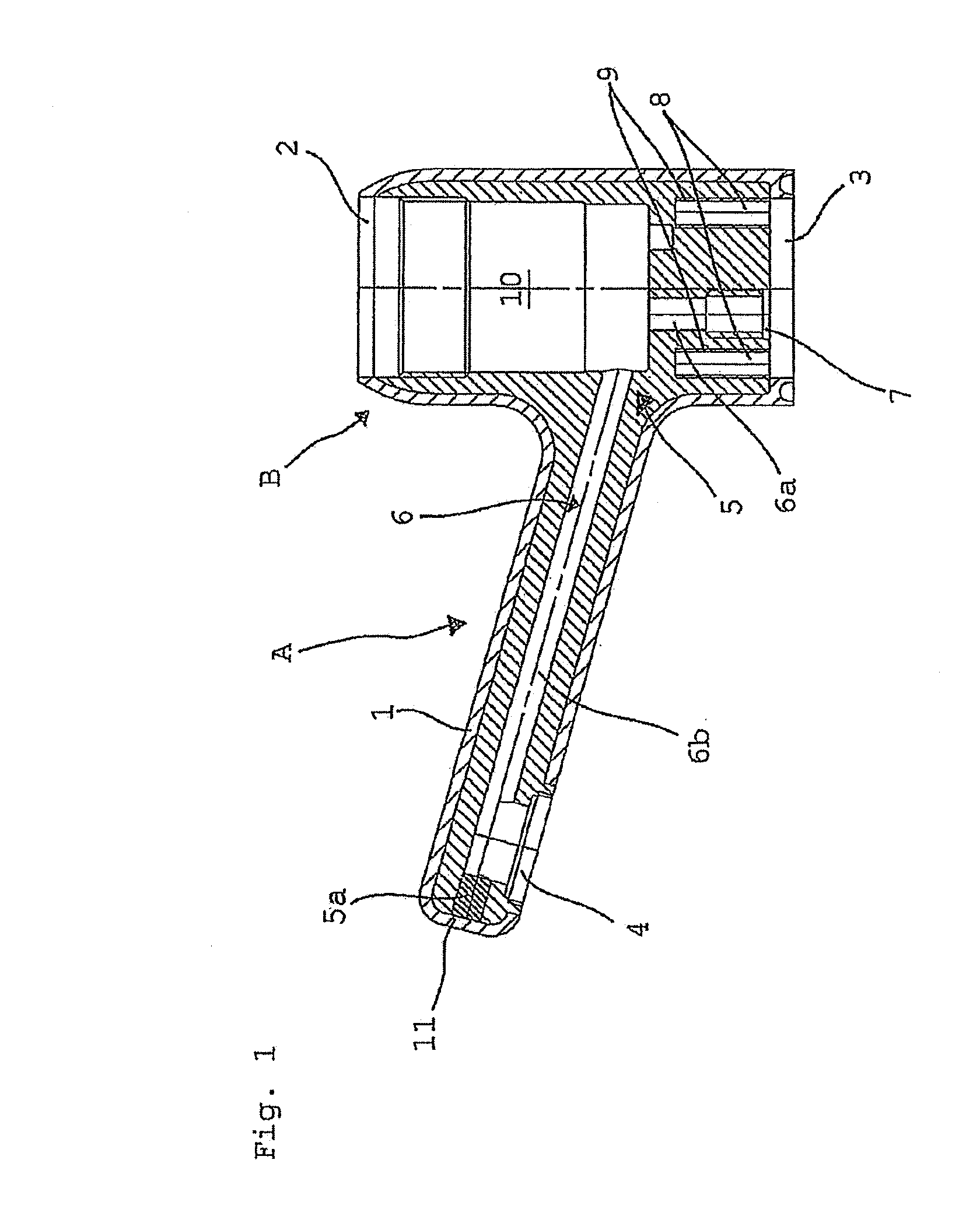

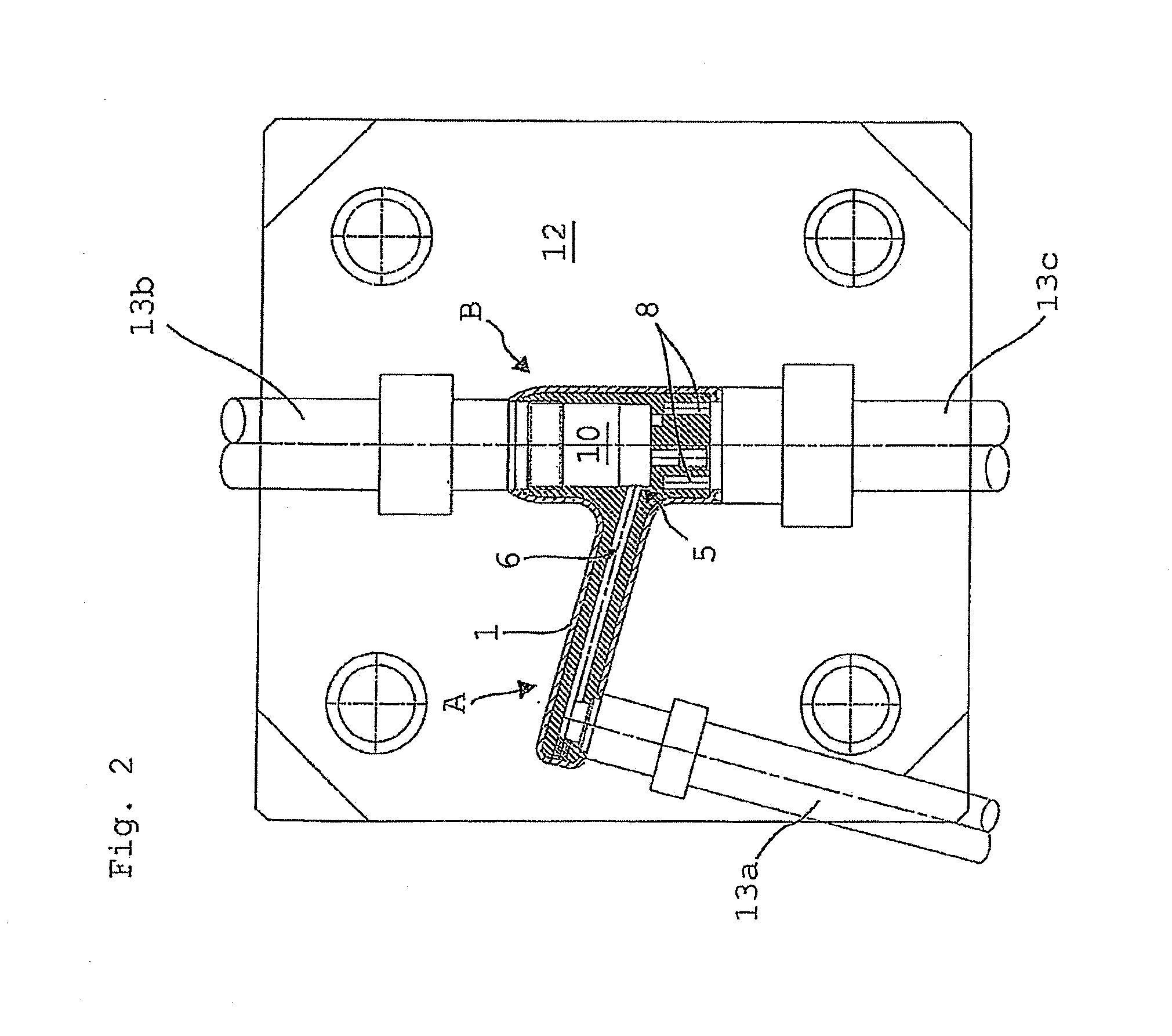

[0041]FIG. 1 shows a cast component according to the invention which is in the form of a water outlet fitting. The latter comprises a base body produced by the die casting method which here forms the housing 1 of the water outlet fitting and is made of a metal alloy suitable for die casting, in particular a zinc alloy, an aluminum alloy or a magnesium alloy.

[0042]The housing 1 of the water outlet fitting is made hollow and is formed by a substantially cylindrical base section B and an arm A projecting from the latter to the side. At the upper end of the cylindrical base section B there is an opening 2 for a flow regulation apparatus that is not drawn in. On its lower side the cylindrical base section B further comprises an opening 3 for the supply of water and the fastening of the water outlet fitting to a further component, in particular to a wash basin (not shown). On the lower side of the projecting arm A there is a water outlet opening 4 in the region of which a threaded hole e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com