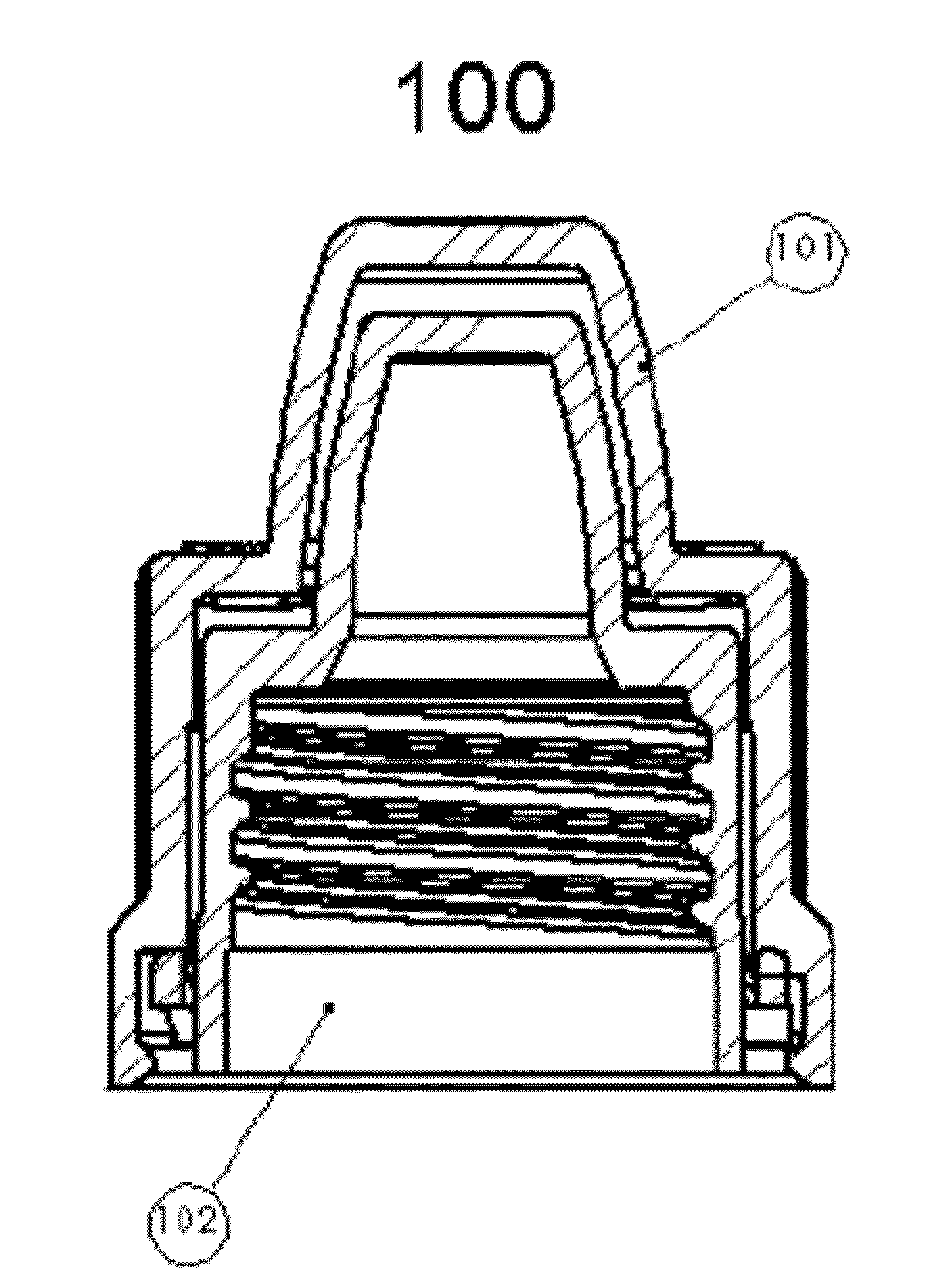

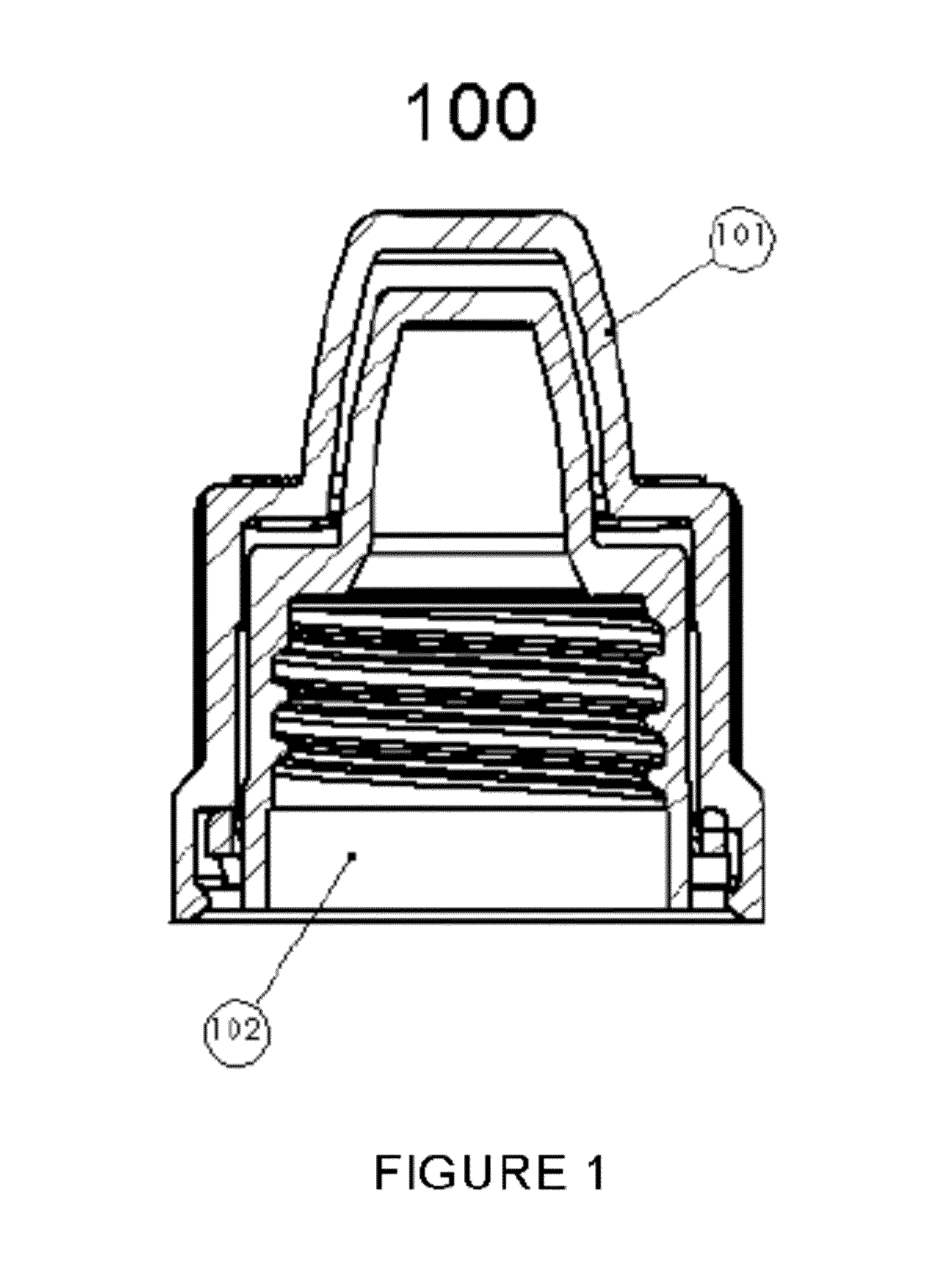

Child-Resistant Cap for Liquid Medicaments

a dispenser and child-resistant technology, applied in the field of child-resistant dispenser closures, can solve the problems of cap not being opened, prior-art caps implementation, finger damage, etc., and achieve the effect of enhancing child-resistant properties and ease of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

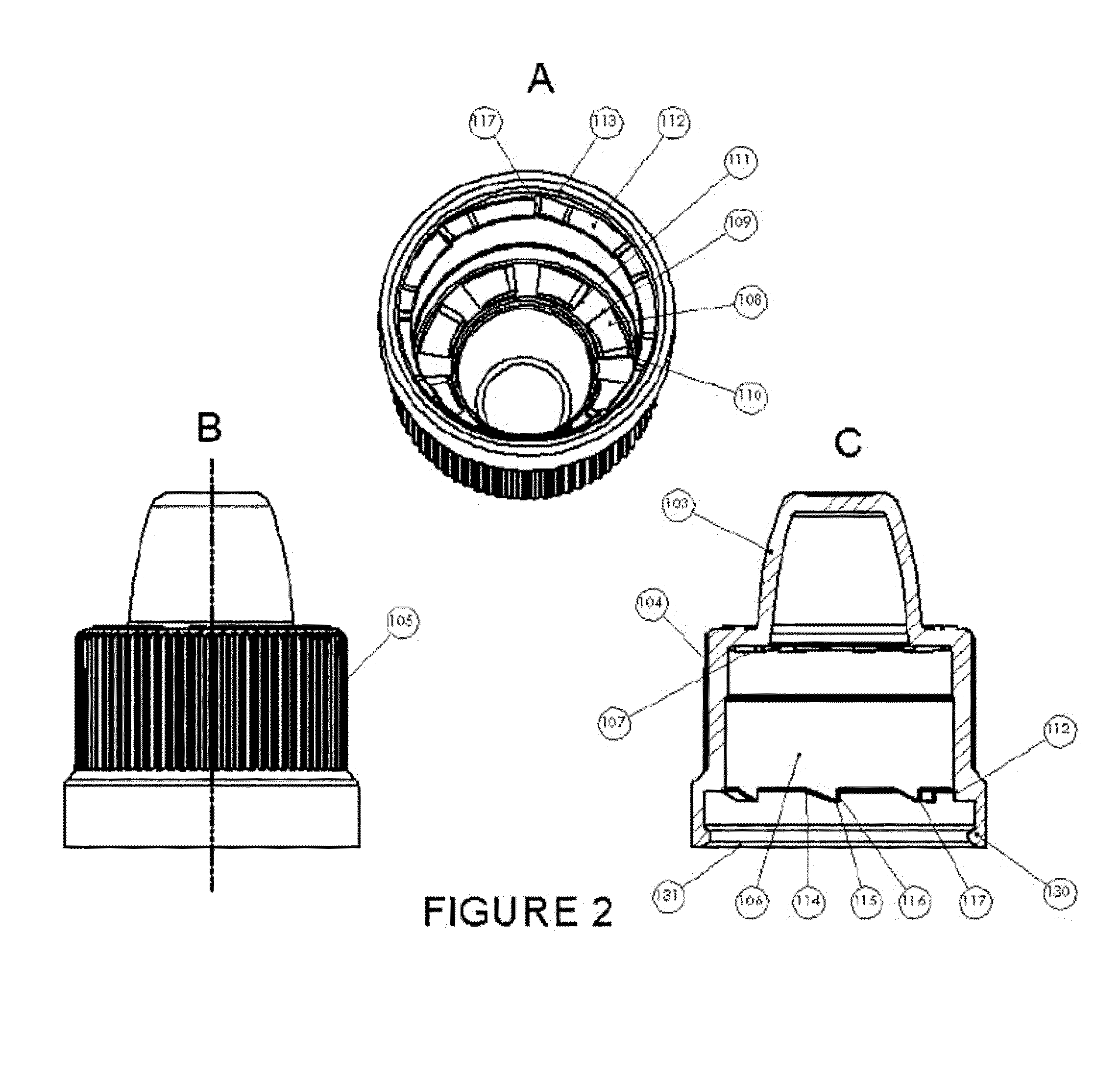

[0024]For the purposes of the present disclosure, the term “overlap” shall be understood to mean the horizontal distance measured from the vertical plane of a lug face of a skirt lug to the vertical plane of the nearest beam face of a flexible beam, when the lug faces of shoulder lugs on inner and outer caps are aligned.

[0025]For the purposes of the present disclosure, the term “lug” shall be understood to include both male lugs and female lugs. Thus, discussion of “lugs” engaging one another shall be understood to include complementary male and female lugs engaging one another, two or more male lugs engaging one another, as well as two or more female lugs engaging one another. Similarly, discussions of flexible beams engaging lugs shall be understood to include engagement of male or female lugs by a flexible beam.

[0026]For the purposes of the present disclosure, the term “depth,” when referring to lugs, shall be understood to be a measure of the change in vertical length between a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com