Method of replacing silicon with metal in integrated circuit chip fabrication

a technology of integrated circuits and metal contacts, which is applied in the direction of semiconductor devices, electrical equipment, transistors, etc., can solve the problems of increasing chip power consumption, increasing cooling and packaging costs, and typical fets being much more complex than switches, so as to reduce the pinch off of replacement metal contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

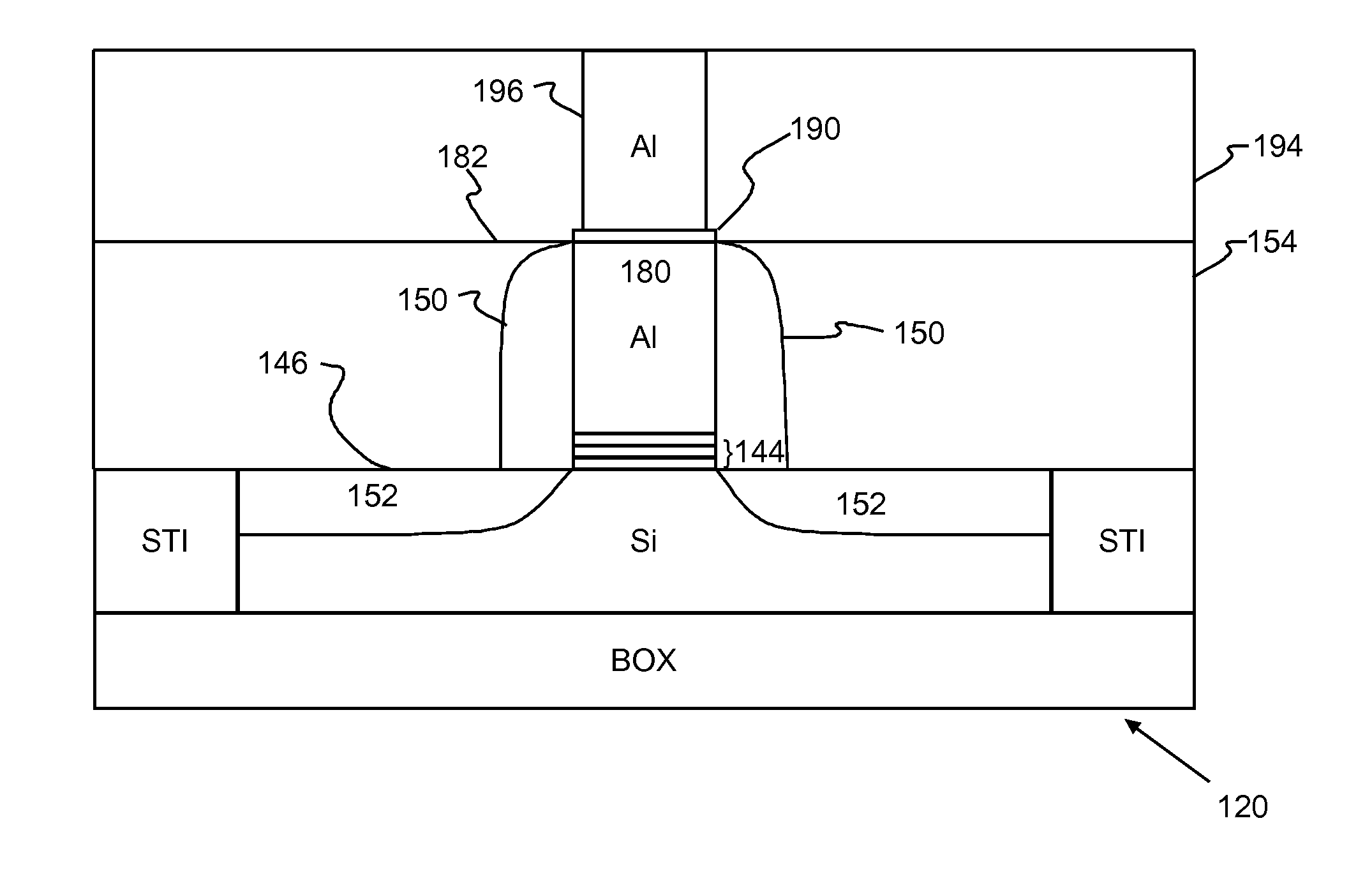

[0036]Turning now to the drawings and, more particularly, FIG. 1 shows an example of a method 100 of forming semiconductor devices, Replacement Metal Gate (RMG) gate Field Effect Transistors (FETs) or RMGFETs, as well as optionally or alternately form Replacement Metal Contacts (RMCs), according to a preferred embodiment of the present invention. Although described with reference to silicon on insulator (SOI) technology, and more particularly CMOS, the present invention has application to any suitable replacement metal technology. Further, the preferred method 100 has application to forming ICs with only RMGFETs or RMC or both.

[0037]IC fabrication begins with a preparing 102 a semiconductor wafer, e.g., an SOI wafer. Device locations are defined 104 on the silicon surface layer of the multilayered SOI wafer. Semiconductor, preferably silicon, gates are formed 106 in the device locations. Metal, preferably aluminum (Al), is deposited 110 on the silicon gates. The wafer is annealed 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com