Feeding control mechanism of packaging machine

a control mechanism and packaging machine technology, applied in mechanical conveyors, packaging, loading/unloading, etc., can solve the problems of deteriorating the overall operation efficiency of the packaging machine, increasing labor costs, and inability to handle these products, and achieves smooth performance of the subsequent packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

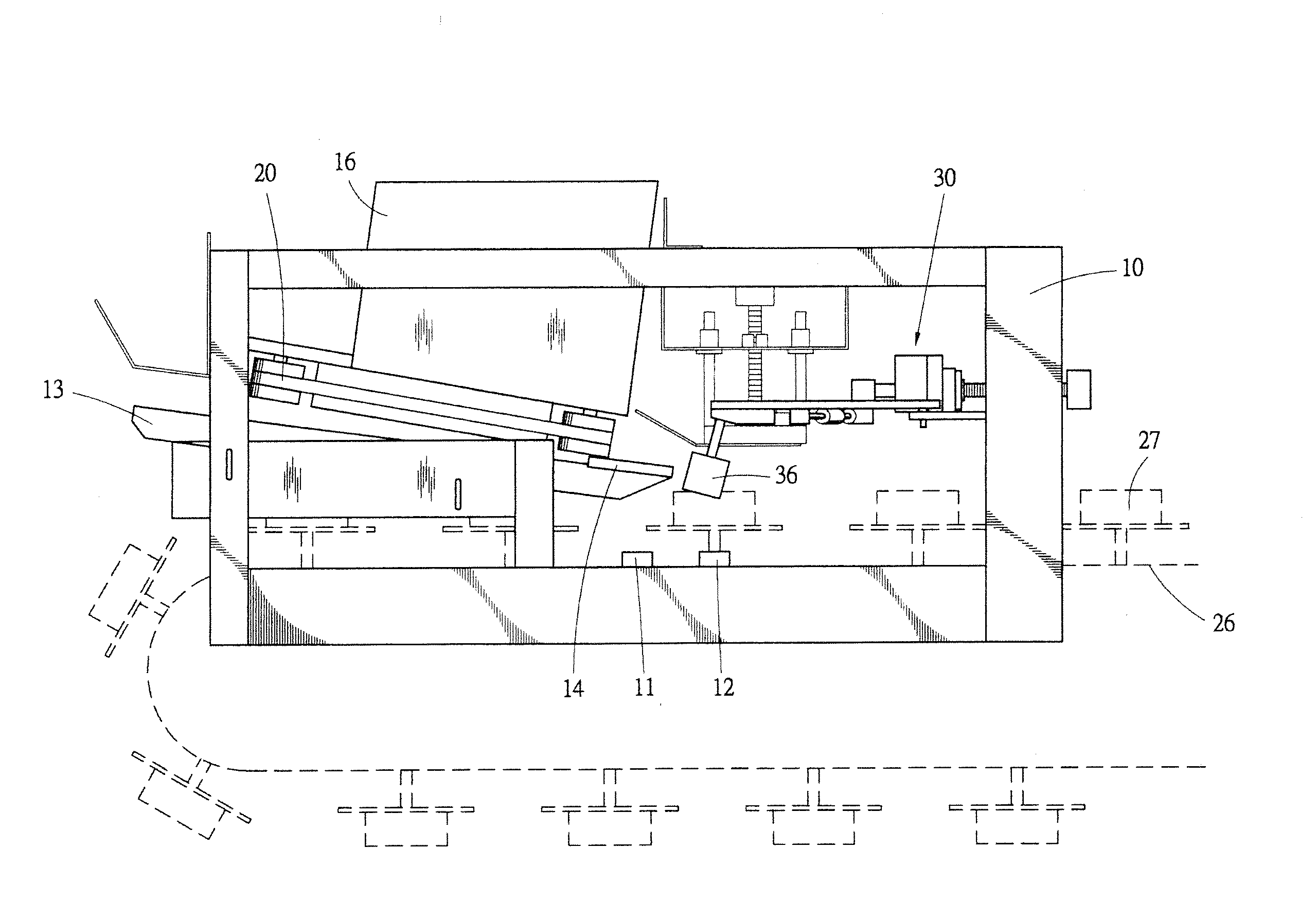

[0021]FIG. 1 of the attached drawings is an exploded view of a feeding control mechanism of packaging machine according to the present invention.

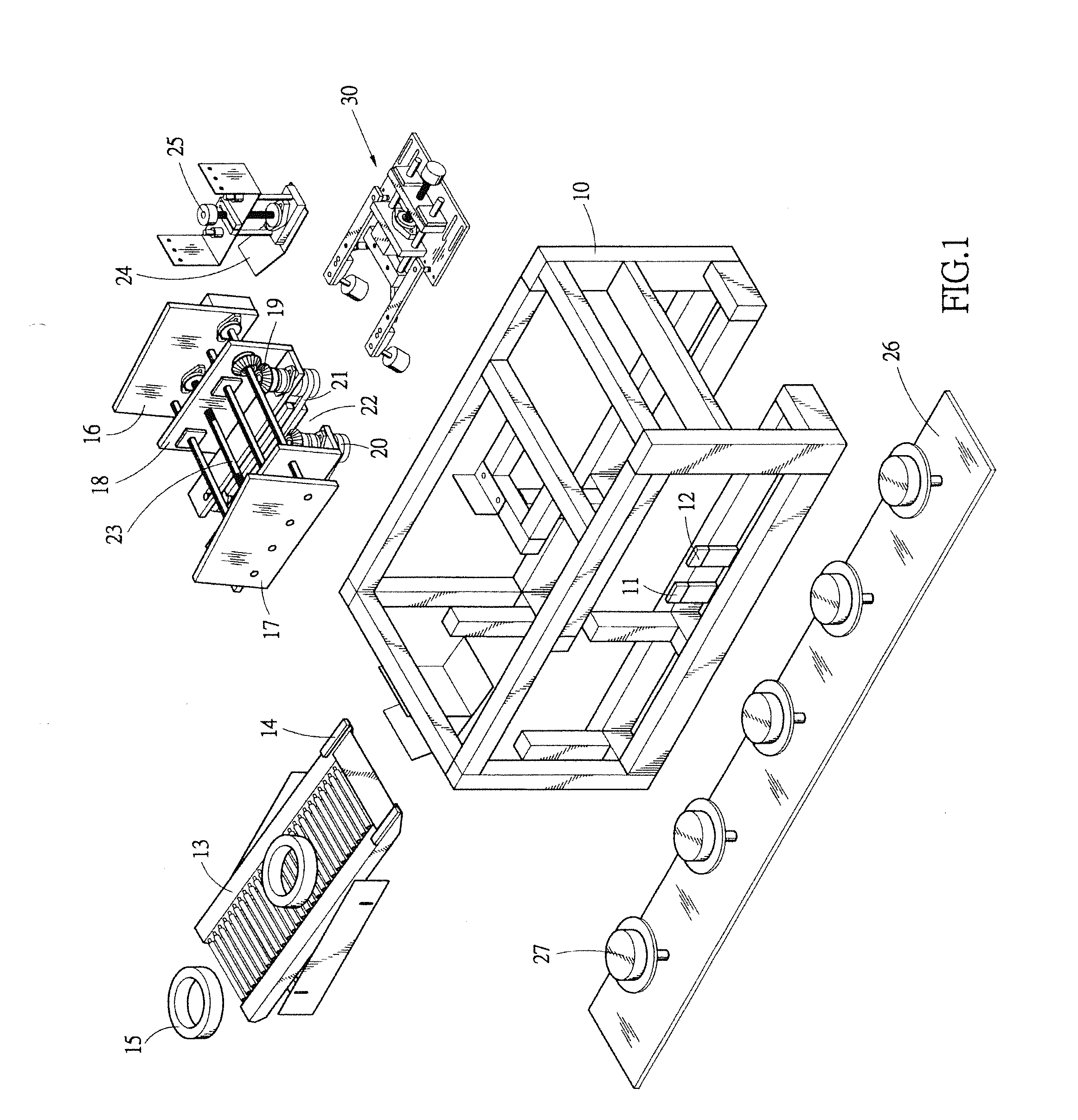

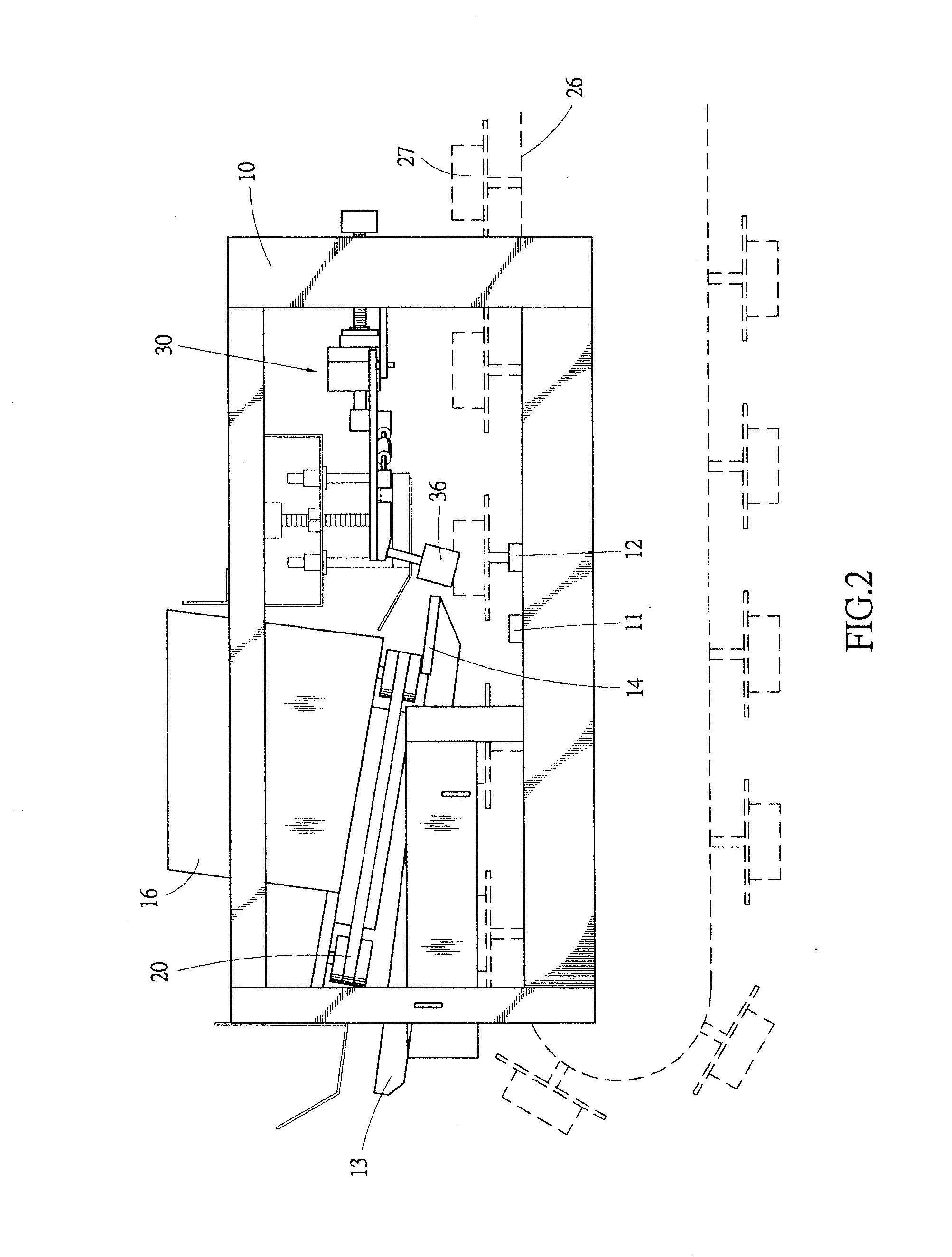

[0022]FIG. 2 is a side elevational view of the feeding control mechanism of packaging machine according to the present invention.

[0023]As shown in FIGS. 1 and 2, the feeding control mechanism of packaging machine according to the present invention generally comprises a chassis 10, a feeding guide 13, a forwarding device 16, a conveyor belt 26, and a feeding controller 30.

[0024]As shown in FIG. 1, the chassis 10 supports various components of the feeding control mechanism mounted thereon, including a first sensor 11 and a second sensor 12 that are mounted along one side of a moving path of a conveyor belt 26 mounted in the chassis 11 to detect product trays 27 of the conveyor belt 26.

[0025]As shown in FIG. 1, the feeding guide 13 is arranged at a front side of the chassis 10. The feeding guide 13 has a surface at one side of which a feed-in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com