Lightweight closure and container package

a container and closure technology, applied in the field of container packaging, can solve the problems of significant cost associated with the closure of this nature and the polymeric material from which the closure is molded, and achieve the effect of reducing the quantity of polymeric material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]While the present invention is susceptible of embodiment in various forms, there is shown in the drawings and will hereinafter be described a presently preferred embodiment, with the understanding that the present disclosure is to be considered as an exemplification of the invention, and is not intended to limit the invention to the specific embodiment illustrated.

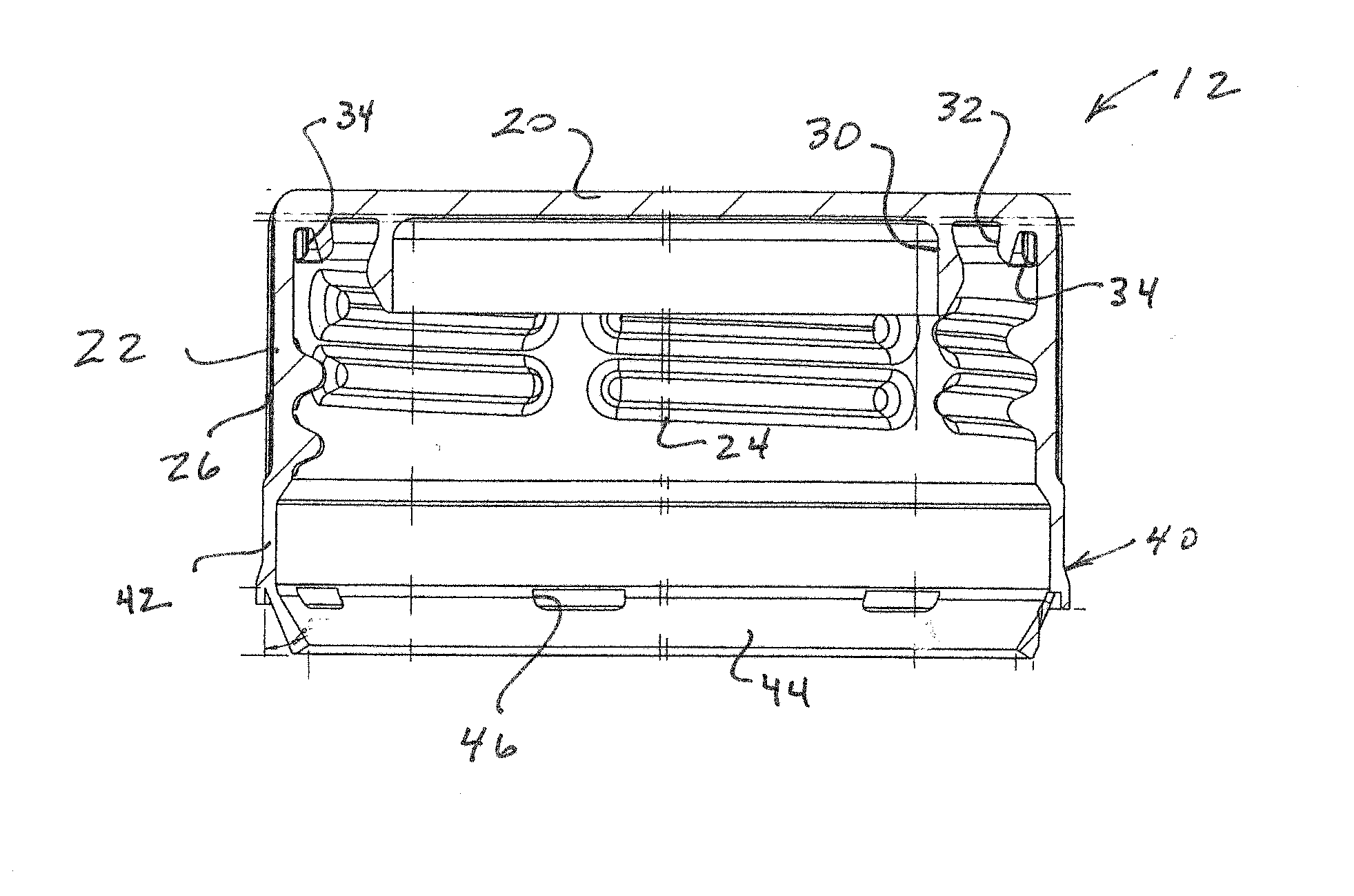

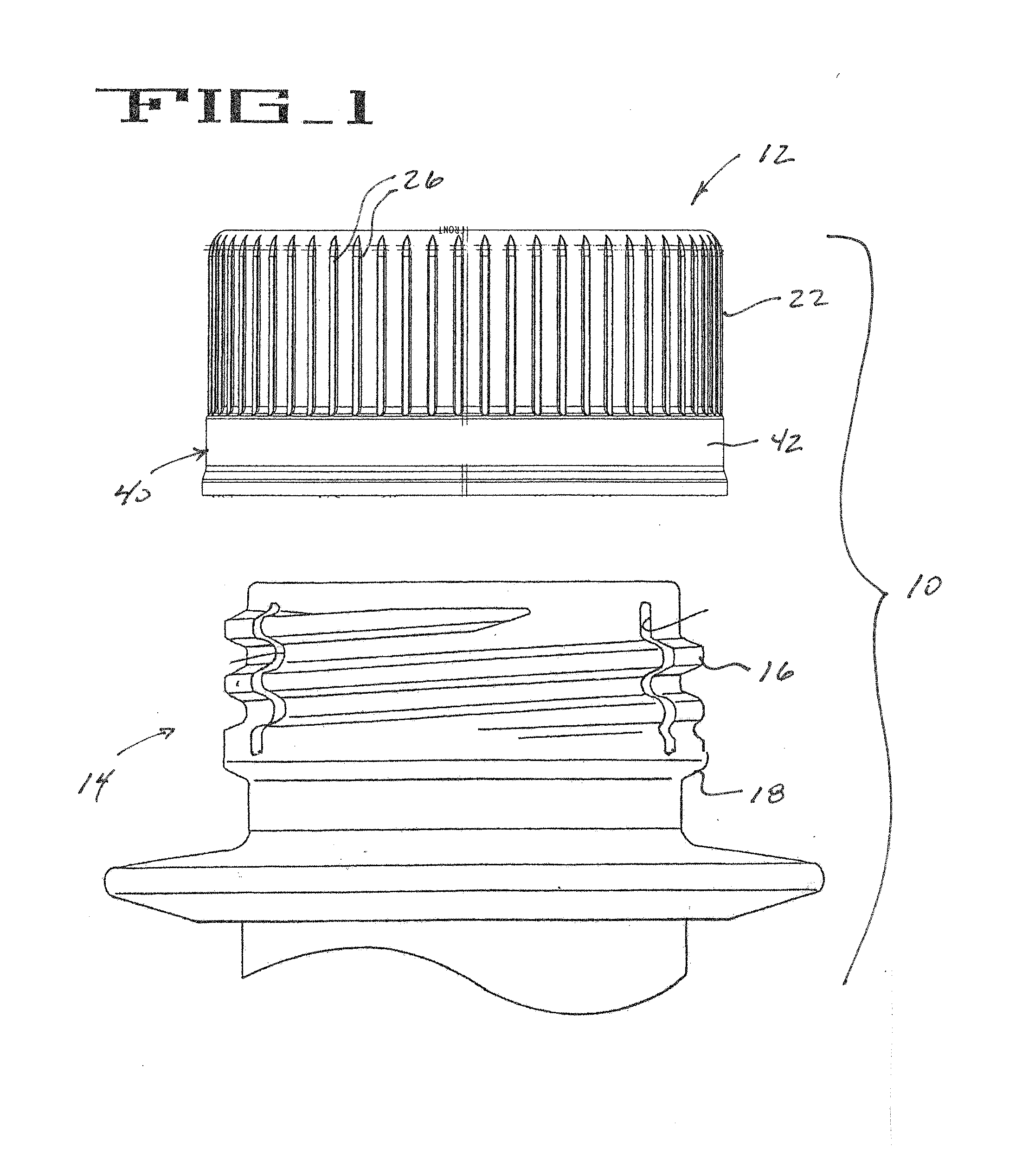

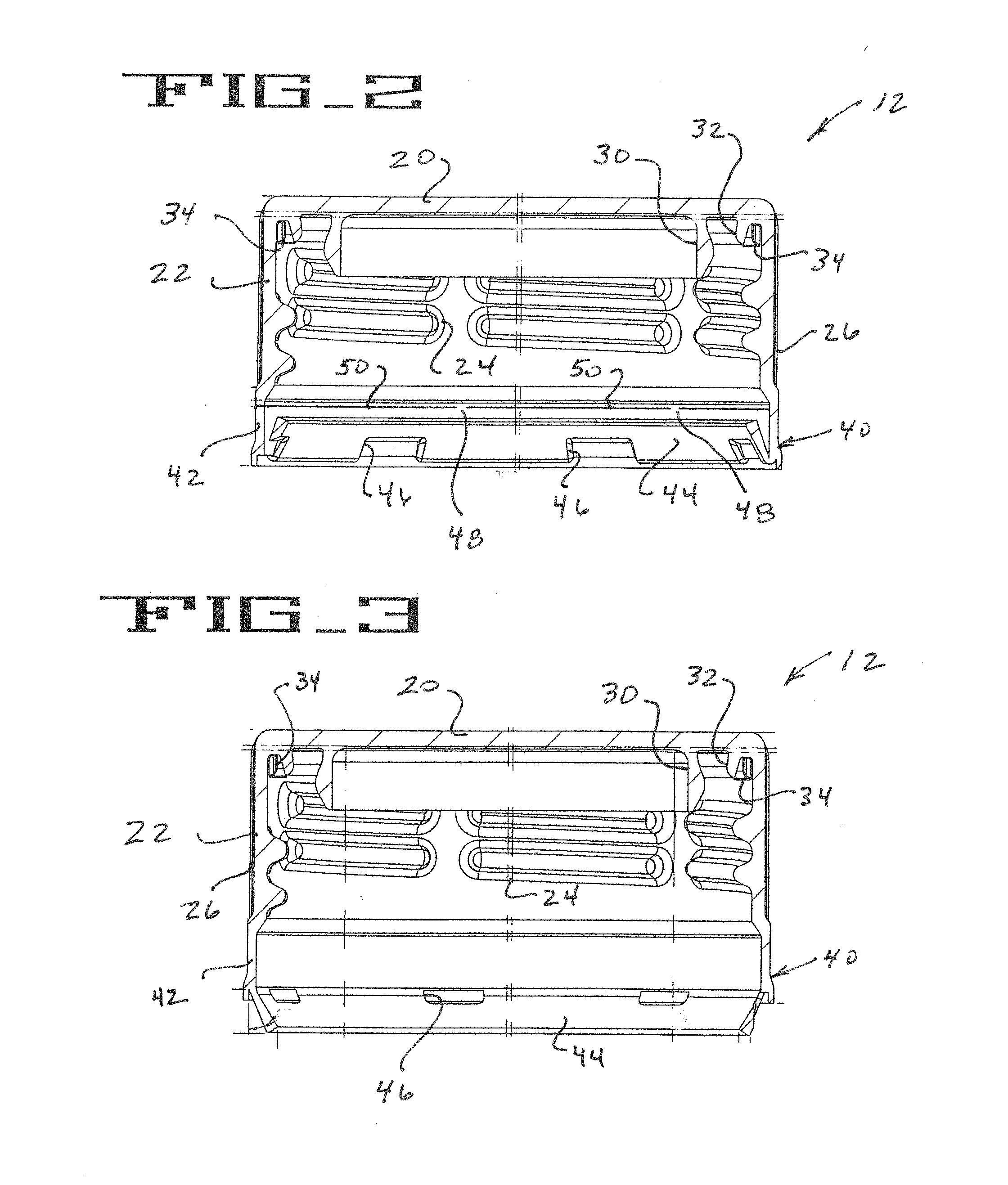

[0021]With reference now to the drawings, therein is illustrated a closure and container package 10 for carbonated or otherwise pressurized contents, including a lightweight closure 12 embodying the principles of the present invention, and a container 14 having a threaded neck portion that includes an external, helical thread formation 16. The thread formation terminates at an annular locking ring 18, which cooperates with closure 12 for tamper-indication. As will be familiar to those skilled in the art, providing effective sealing performance for a closure and container package having carbonated contents can be dema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com