Cell wiring module

a cell module and wiring technology, applied in the field of cell wiring modules, can solve the problems of dimensional errors in the cell module and possible mounting failure, and achieve the effect of preventing failure when mounting on a plurality of single cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

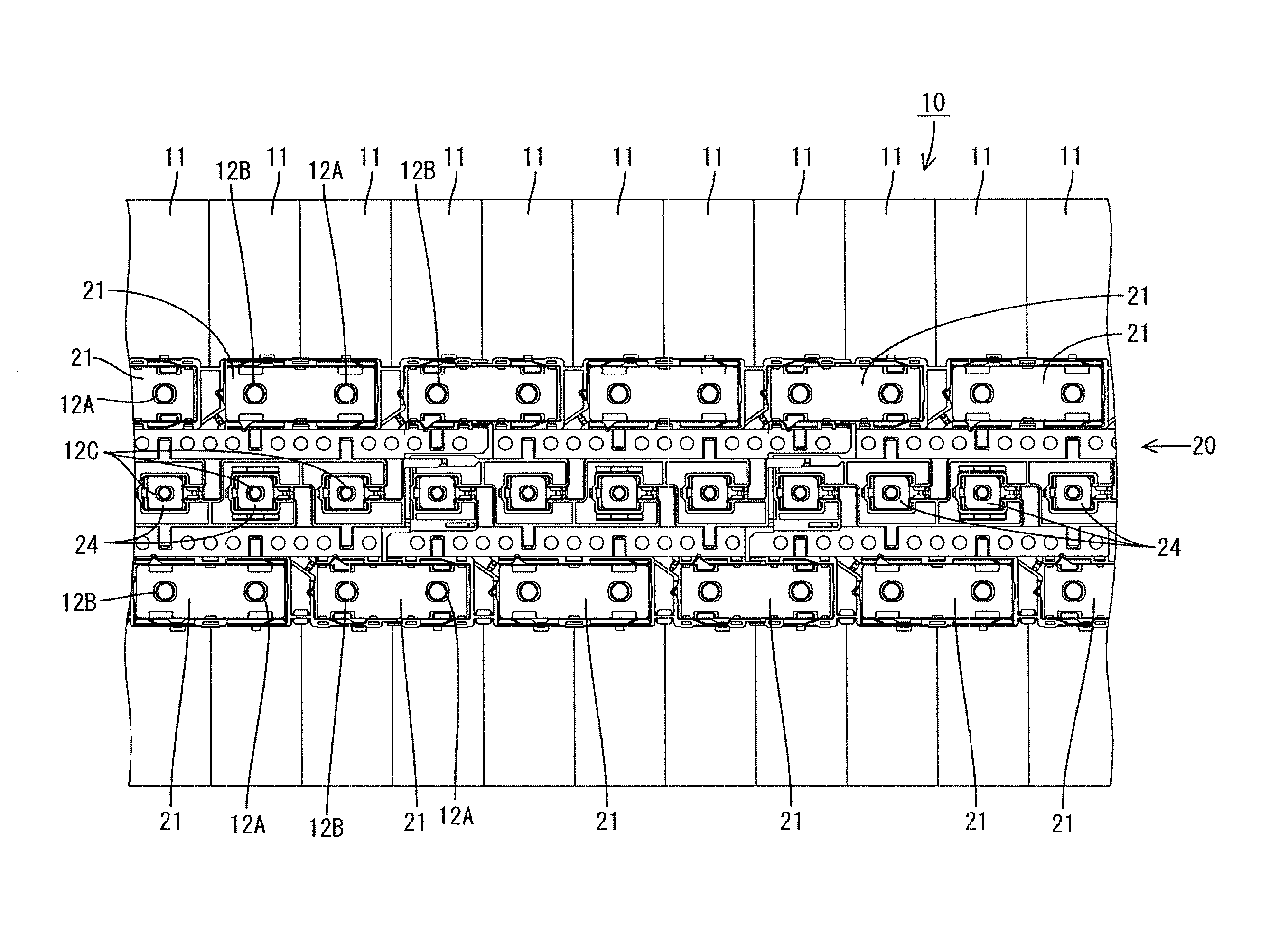

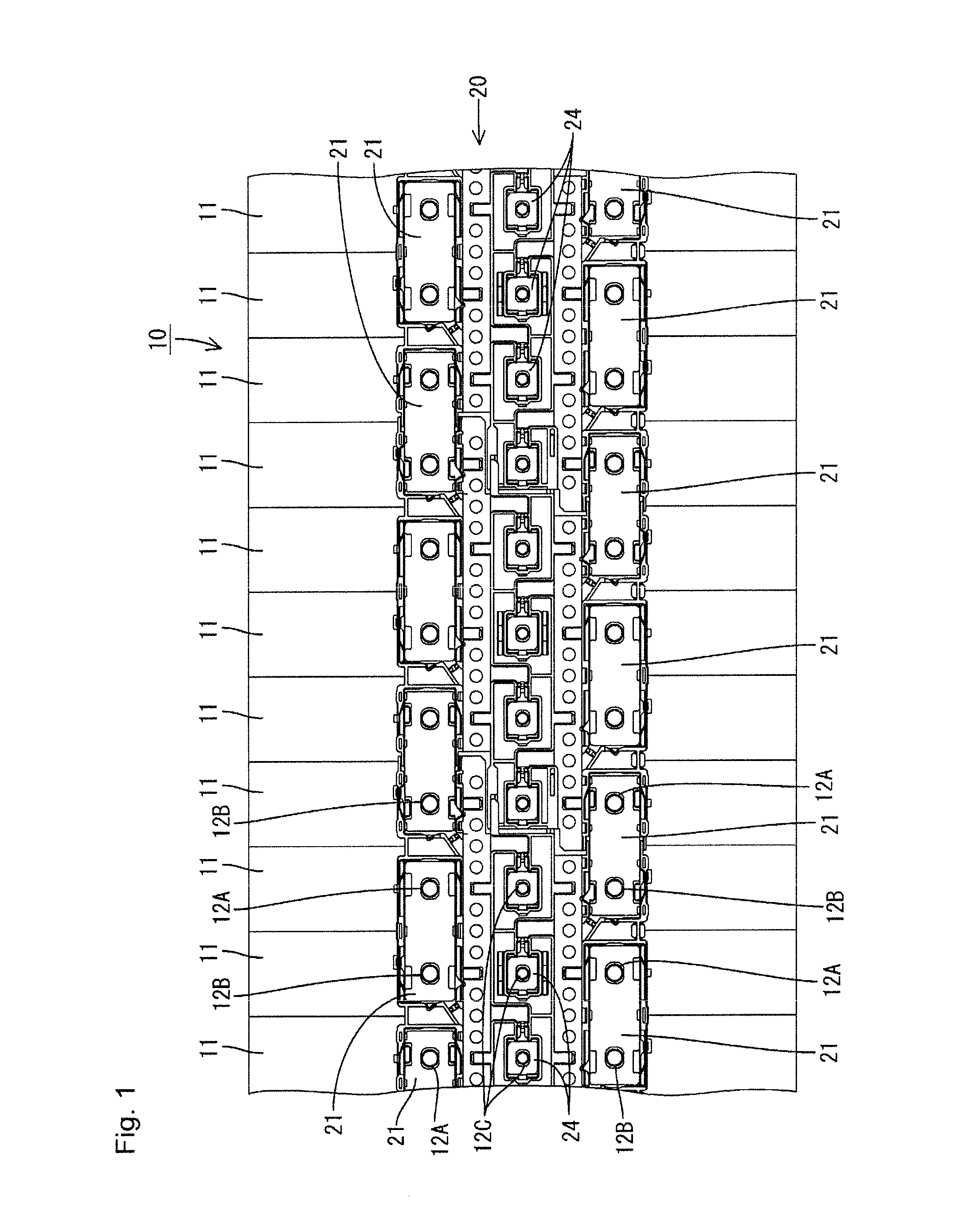

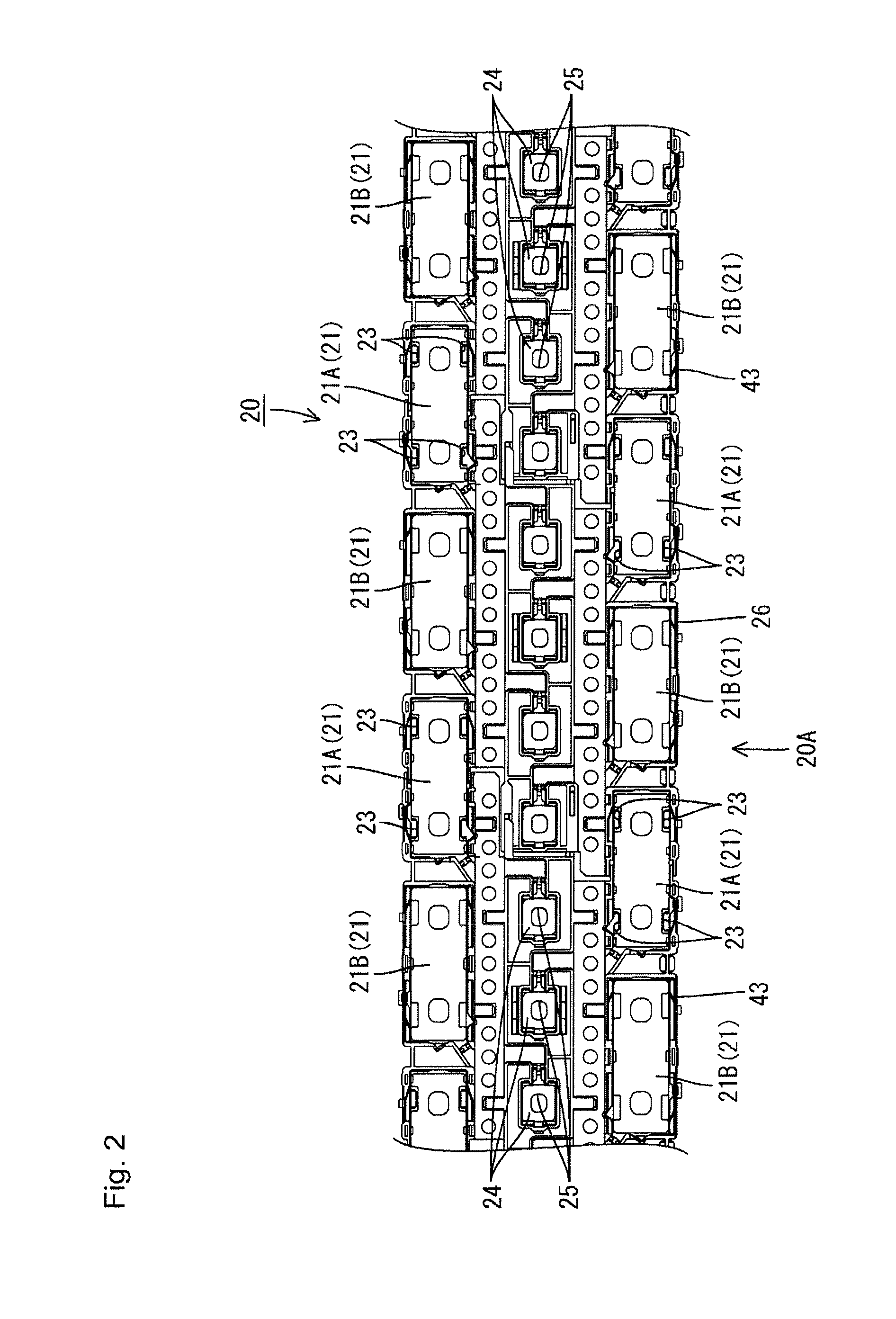

[0042]Hereafter, with reference to FIGS. 1 to 5, a description is given of an embodiment of the present invention. A cell wiring module 20 of the present embodiment connects, with a connection member 21, electrode terminals 12A and 12B of adjacent single cells 11. The cell wiring module 20 is attached to a cell module 10, which is used as a vehicle power source in an electric or hybrid automobile, for example. Hereafter, the description is given with upward in FIG. 1 treated as forward and downward treated as rearward for a front-back direction, while a near face of a sheet of FIG. 1 is treated as upward and a far face of the sheet is treated as downward for a vertical direction.

[0043](Cell Module)

[0044]As shown in FIG. 1, the cell module 10 is configured to include, for example, a plurality (eleven, in FIG. 1) of the single cells 11 (a bank of single cells) and the cell wiring module 20 connecting the plurality of single cells 11.

[0045](Single Cell)

[0046]The single cells 11 include...

embodiment 2

[0090]Embodiment 2 is described with reference to FIGS. 6 to 11. Hereafter, the description is given with upward in FIG. 6 treated as forward and downward treated as rearward for the front-back direction, while a near face of a sheet of FIG. 6 is treated as upward and a far face of the sheet is treated as downward for the vertical direction. Moreover, configurations identical to those of Embodiment 1 are given identical reference numerals and descriptions thereof are omitted.

[0091](Cell Module)

[0092]As shown in FIG. 6, a cell module 50 is configured to include, for example, ten (a plurality) of the single cells 11 and a cell wiring module 51 connecting the ten single cells 11. The ten single cells 11 are divided into three rows in a long axis (long side) direction of the top surface of the single cells 11 (a surface having the electrode terminals). Two rows on a left side are stacked in four layers in a short axis direction of the top surface of the single cells 11, and one row on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shapes | aaaaa | aaaaa |

| rigidity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com