Lead-free brass alloy for hot working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

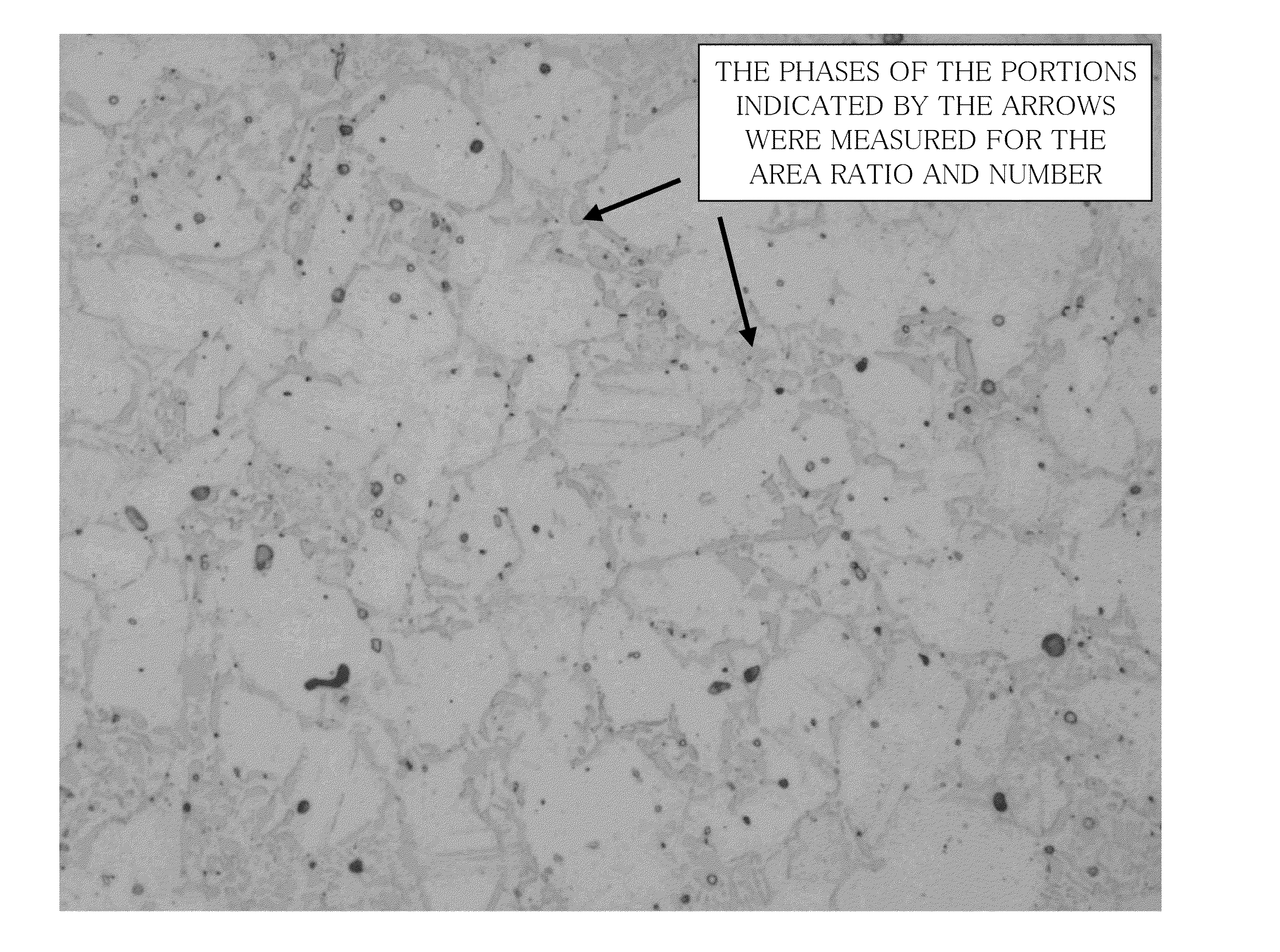

Image

Examples

Example

[0043]Preferred embodiments of the present invention are briefly described below while indicating the effects of the present invention.

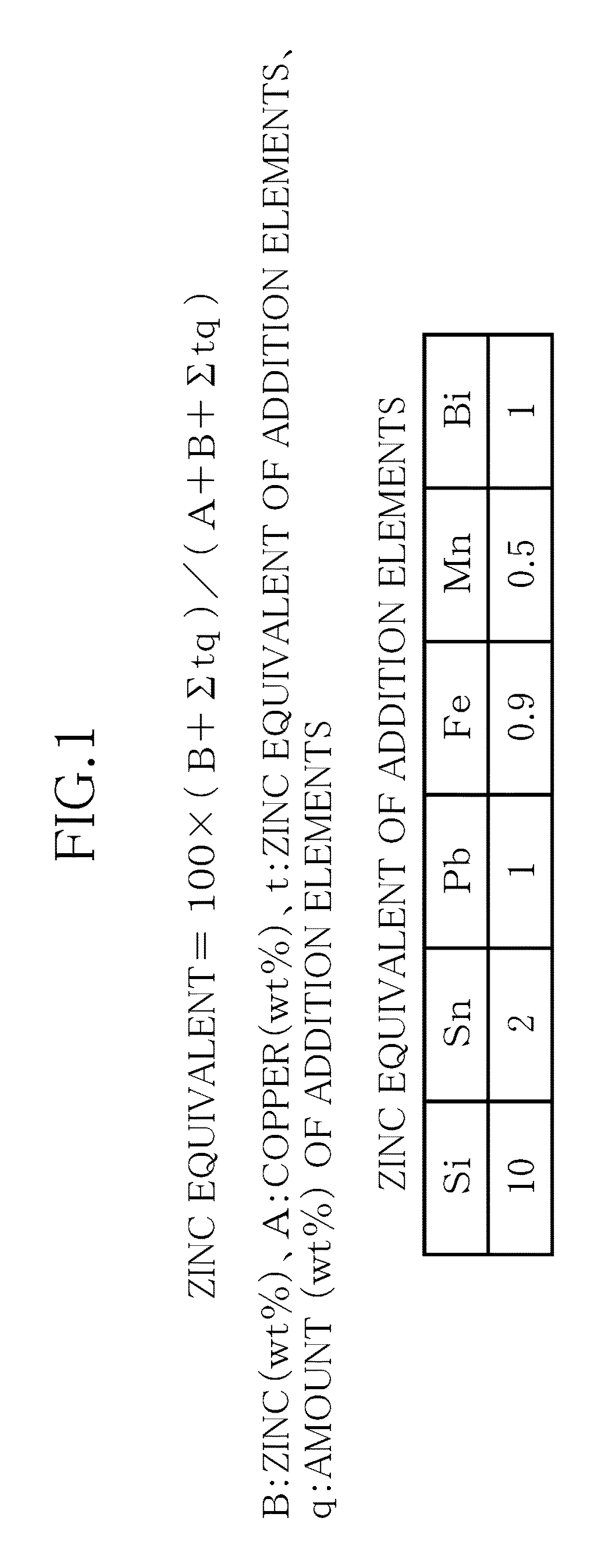

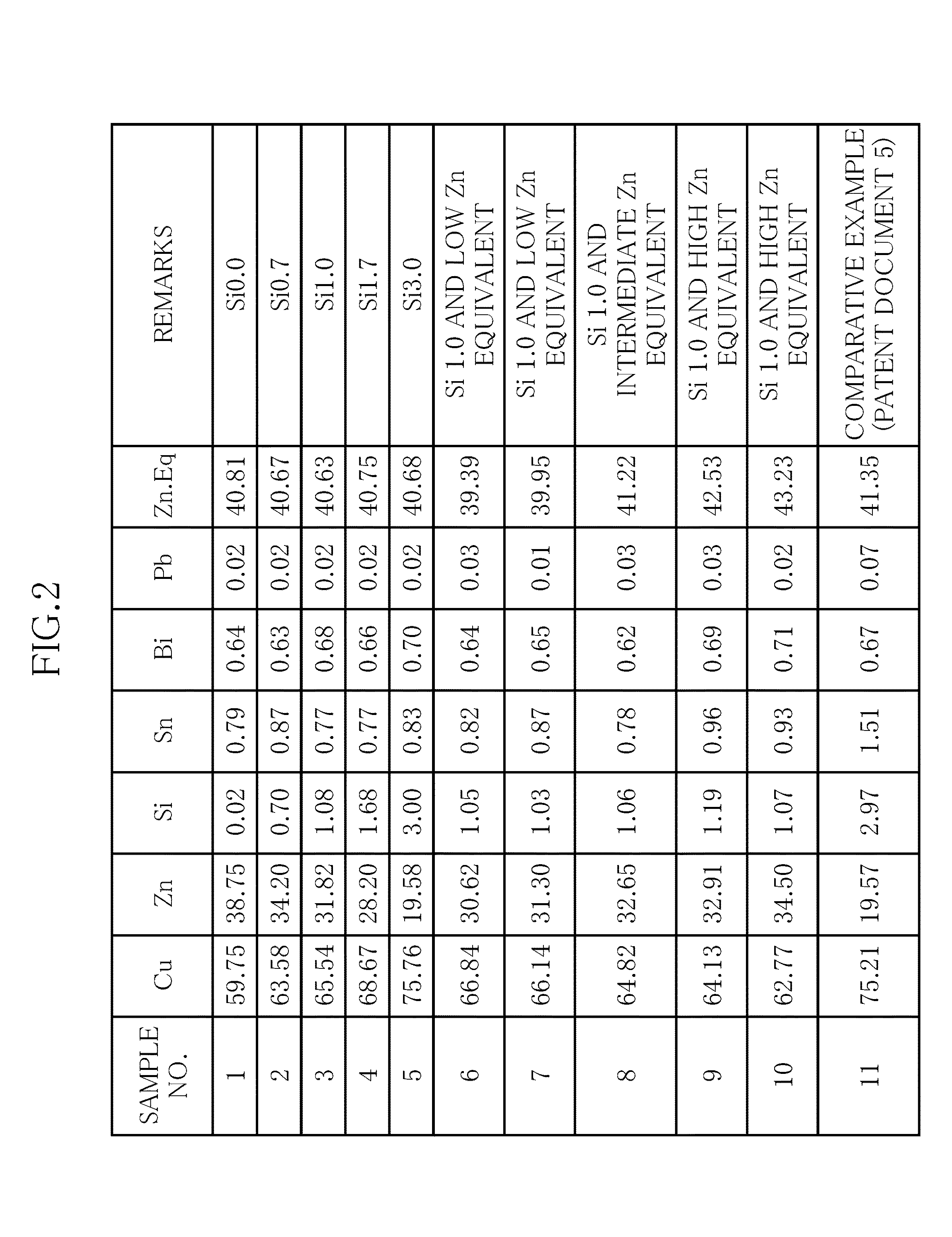

[0044]In order to obtain good resistance to dezincification and resistance to erosion and corrosion, and to provide good hot-working properties and mechanical characteristics, the present invention provides a lead-free brass alloy for hot working comprising: 28.0 to 35.0 wt % zinc, 0.5 to 2.0 wt % silicon, 0.5 to 1.5 wt % tin, 0.5 to 1.5 wt % bismuth, 0.10 wt % or less lead, and the remainder being copper and unavoidable impurities, wherein the zinc equivalent is in a range of 40.0 to 43.0.

[0045]The component composition as described above in the present invention, the reasons for specifying the mechanical characteristics, and the effects of the present invention will be briefly described below.

[0046]Zinc (Zn)

[0047]Zinc dissolves in the matrix of a Cu—Zn—Si copper alloy, and has the effect of increasing mechanical strength. Zinc also reduces the melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap