Automatic, periodic plate-freezing

a technology of periodic plate and automatic plate, which is applied in the direction of refrigeration devices, support, light and heating apparatus, etc., can solve the problems of unfrozen box damage and deformation, less efficient freezing methods in many directions, and longer freezing time, so as to prevent damage and deformation, the effect of less efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The invention will now be described with reference to the following drawings:

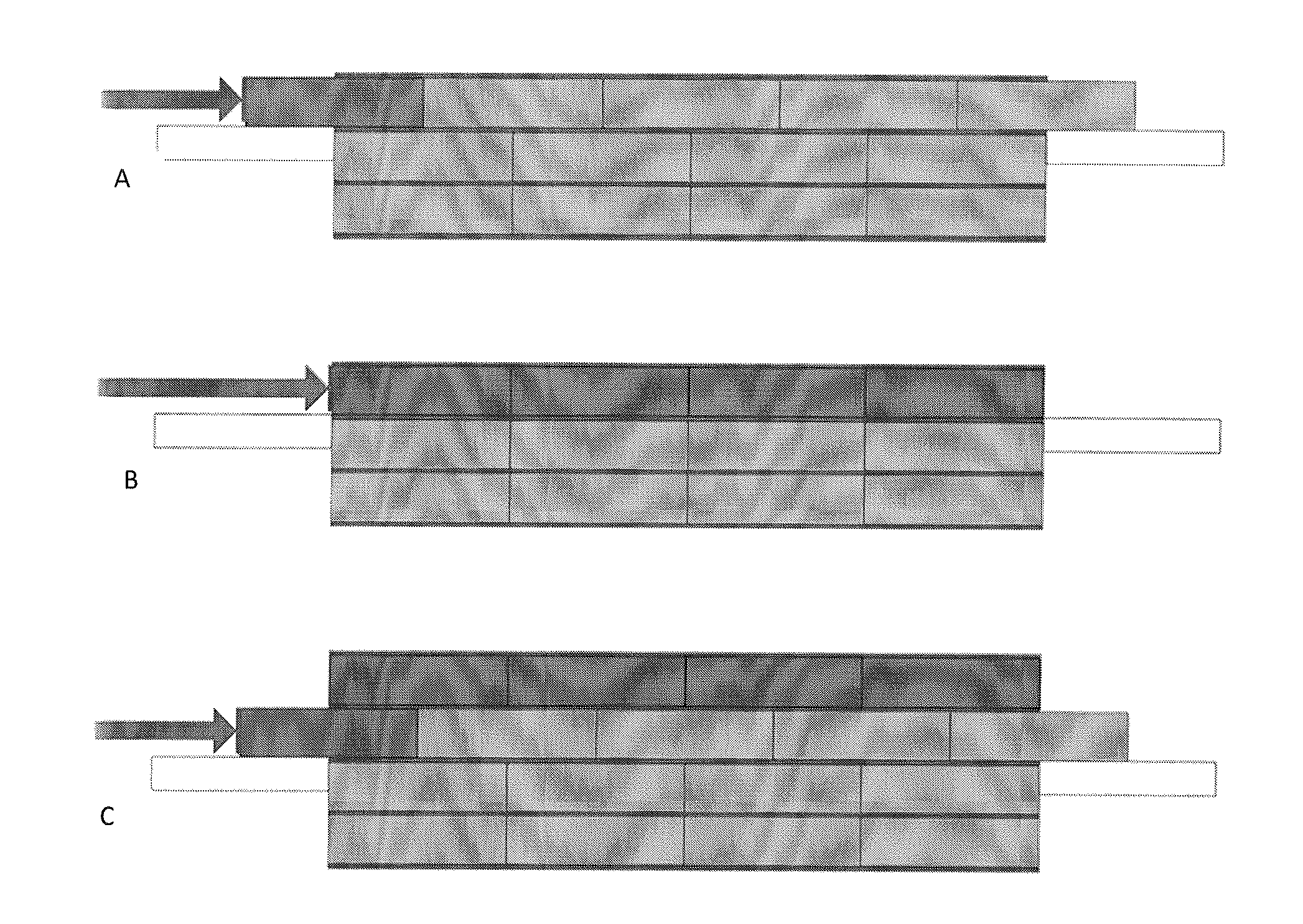

[0035]FIG. 1 shows the process for plate freezing by conventional methods.

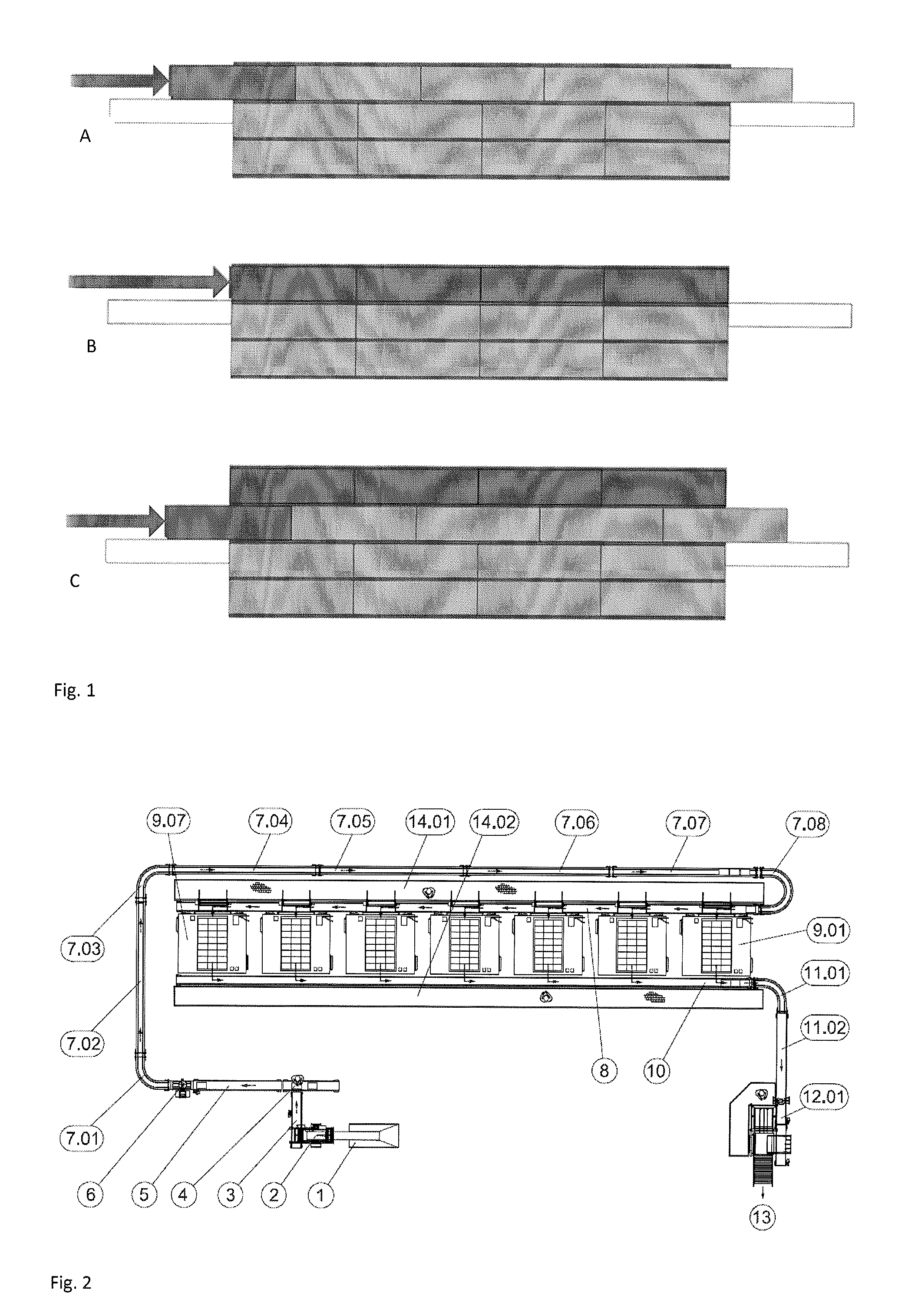

[0036]FIG. 2 shows a specific implementation of the invention and the organization of a freezing system for freezing food items in carton boxes according the method of the invention.

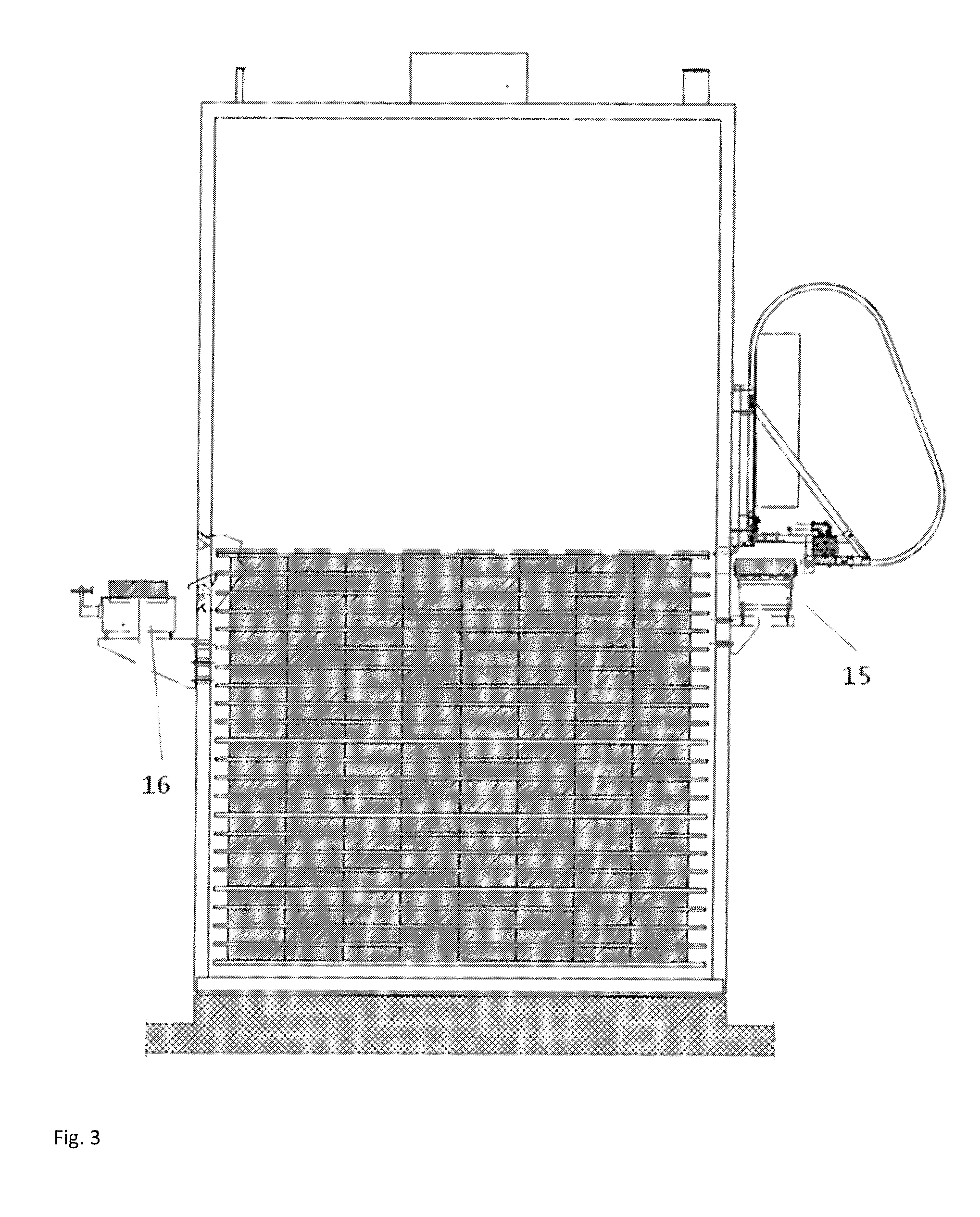

[0037]FIG. 3 shows a cross section of an automatic plate freezer.

[0038]FIG. 4 shows a top view of an automatic plate freezer.

[0039]FIG. 5 shows the process for freezing plate with the method of the present invention.

[0040]FIG. 1 outlines how a traditional method of freezing food objects in boxes is performed. (A) One unfrozen box (shown a dark grey box) is pushed into the first row of a freezer plate and onto a receiver conveyor belt (shown in a white box). As a result one frozen box (shown a light grey box) is pushed out of the last row of the freezer plate. (B) Three more unfrozen boxes have been pushed onto the pate filling rows 1-4 with unfrozen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com