Offshore wind turbine generator connection arrangement and tower system

a technology towers, which is applied in the field of floating wind turbine generators, can solve the problems of wind turbine generators that are inherently large constructions, have significant technical difficulties in installation, operation and maintenance, and have their own technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

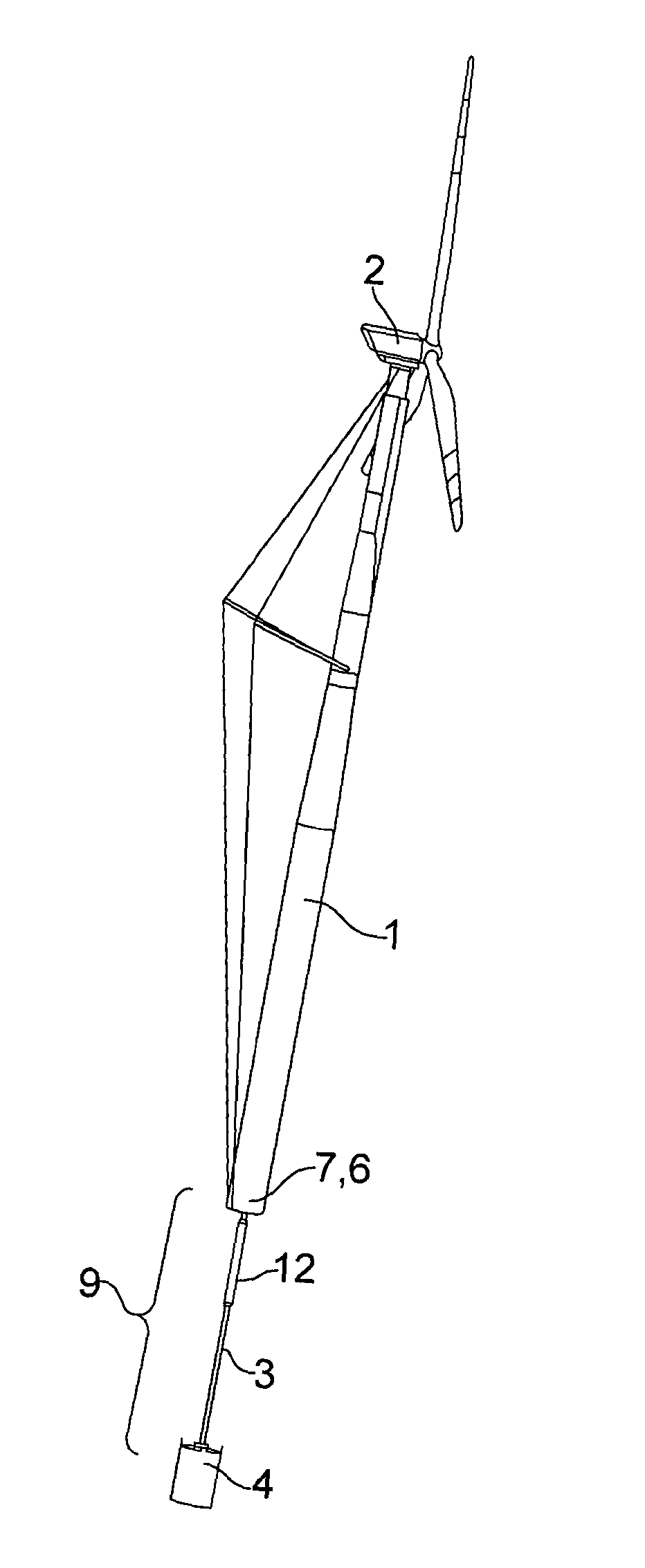

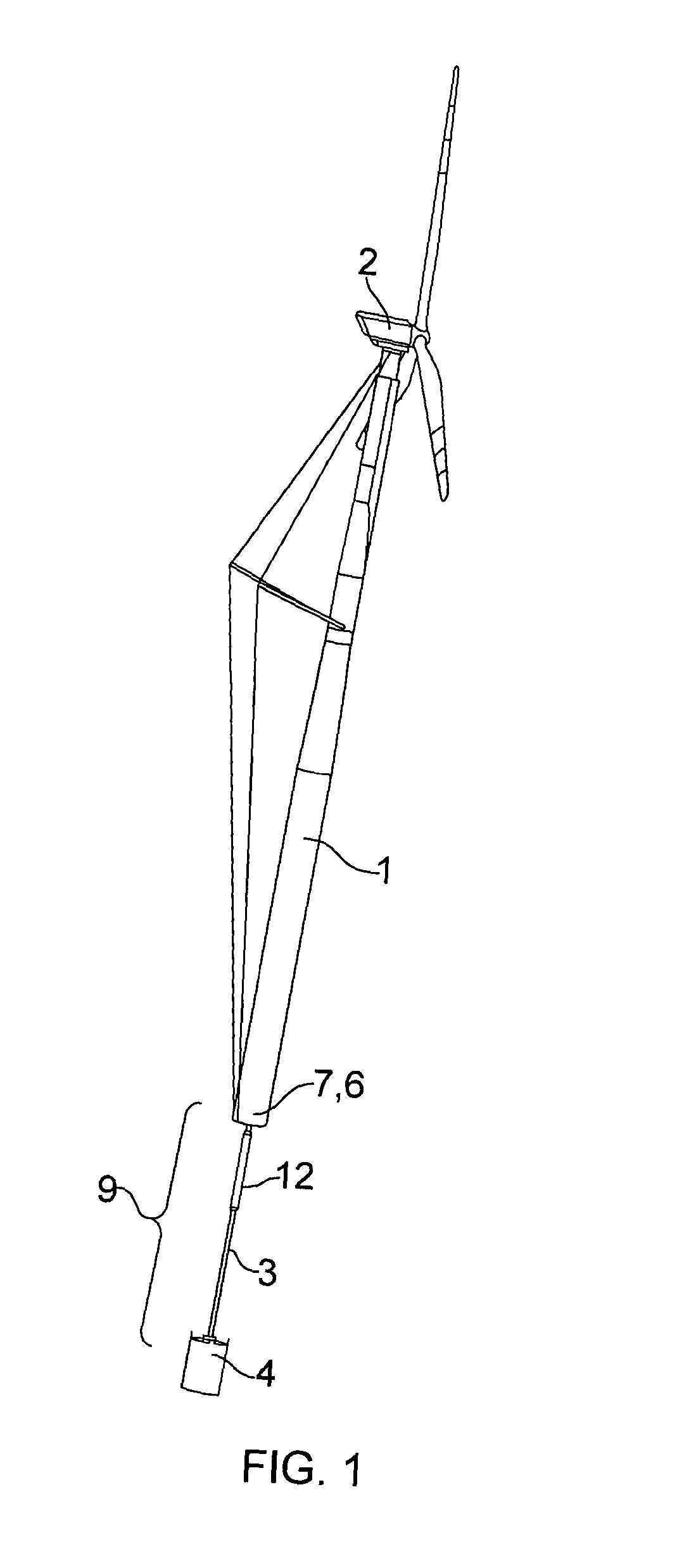

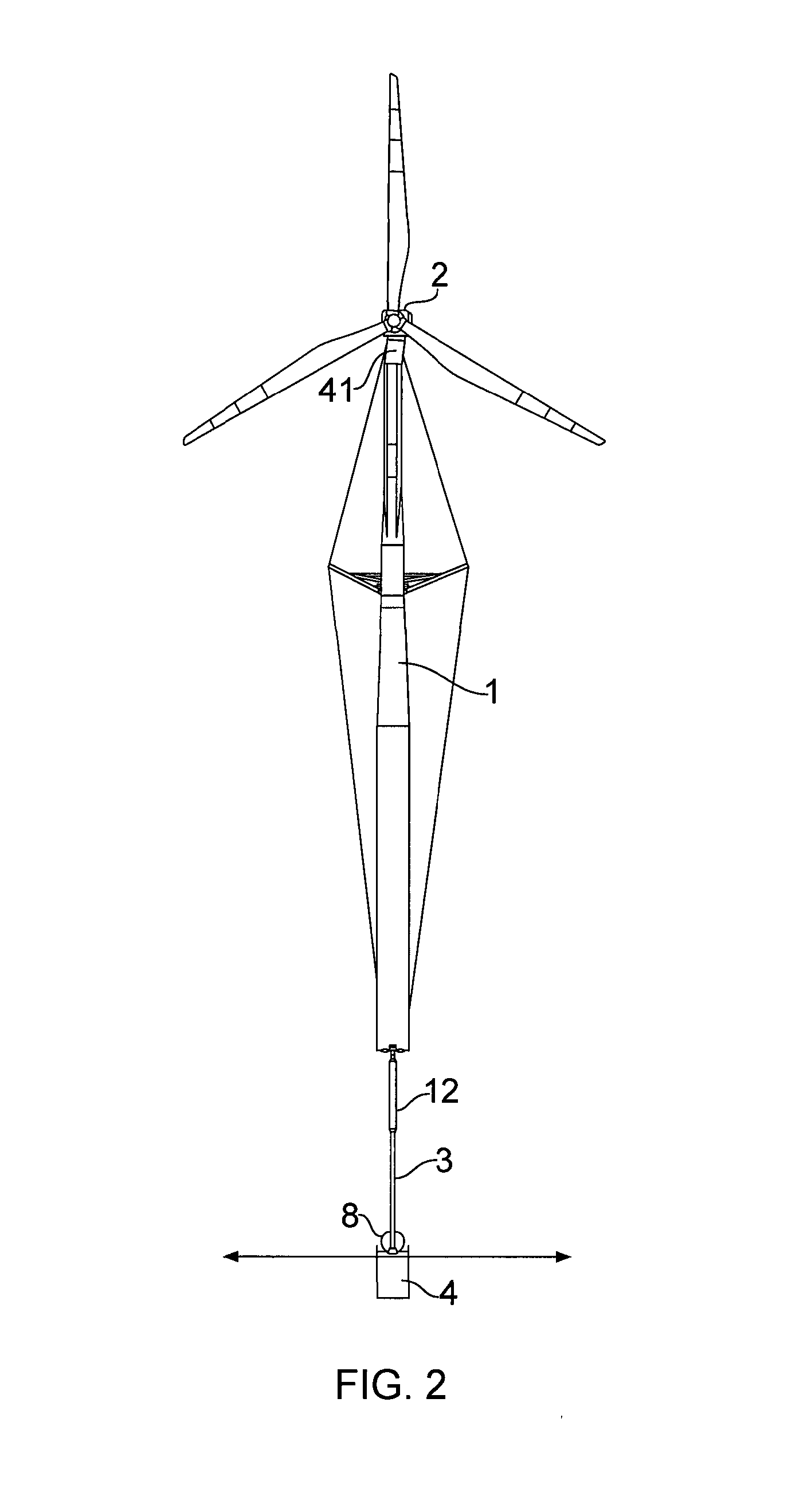

[0041]A preferred embodiment of the invention will now be described with reference to the drawings.

[0042]According to a preferred embodiment, the present invention is an offshore floating wind turbine generator comprising a 186-metre floating tower 1, of which 90 meters raises above sea level and 96 meters plunge into the ocean. A wind turbine 2 is mounted atop the floating tower. The floating tower 1 is anchored to the seabed by a tension leg 3 and an anchor, preferably a suction anchor 4 as shown in FIGS. 1 and 2. The tension leg is arranged to also resist torsion moments (torque) and has the form of a hollow pipe. An upper connection assembly 5 comprising an upper universal joint 6 and a yaw assembly 7 are arranged at the upper end of tension leg 3, while a lower universal joint 8 is arranged at the lower end of tension leg 3 at a connection point with the anchor 4. FIG. 1 further illustrates the wind direction, and an arrangement with spreader beams and tension cables for provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com