Hydrodynamic axial bearing

a technology of axial bearings and rotating shafts, applied in the direction of bearings, water-acting propulsive elements, shafts, etc., can solve the problems of reducing the load-bearing capacity, rubbing of the comb bearing on the floating disk, and affecting the load-bearing force of the mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

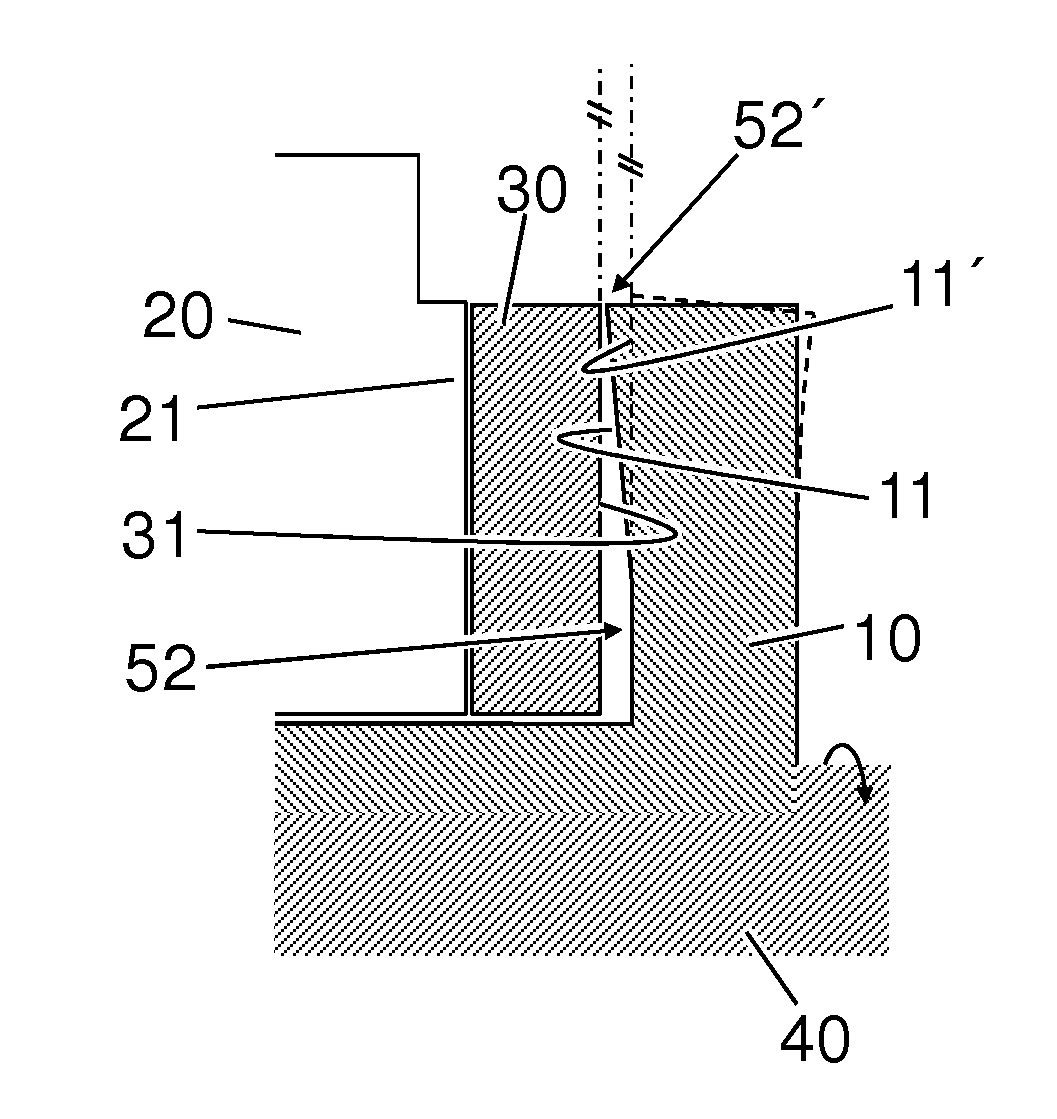

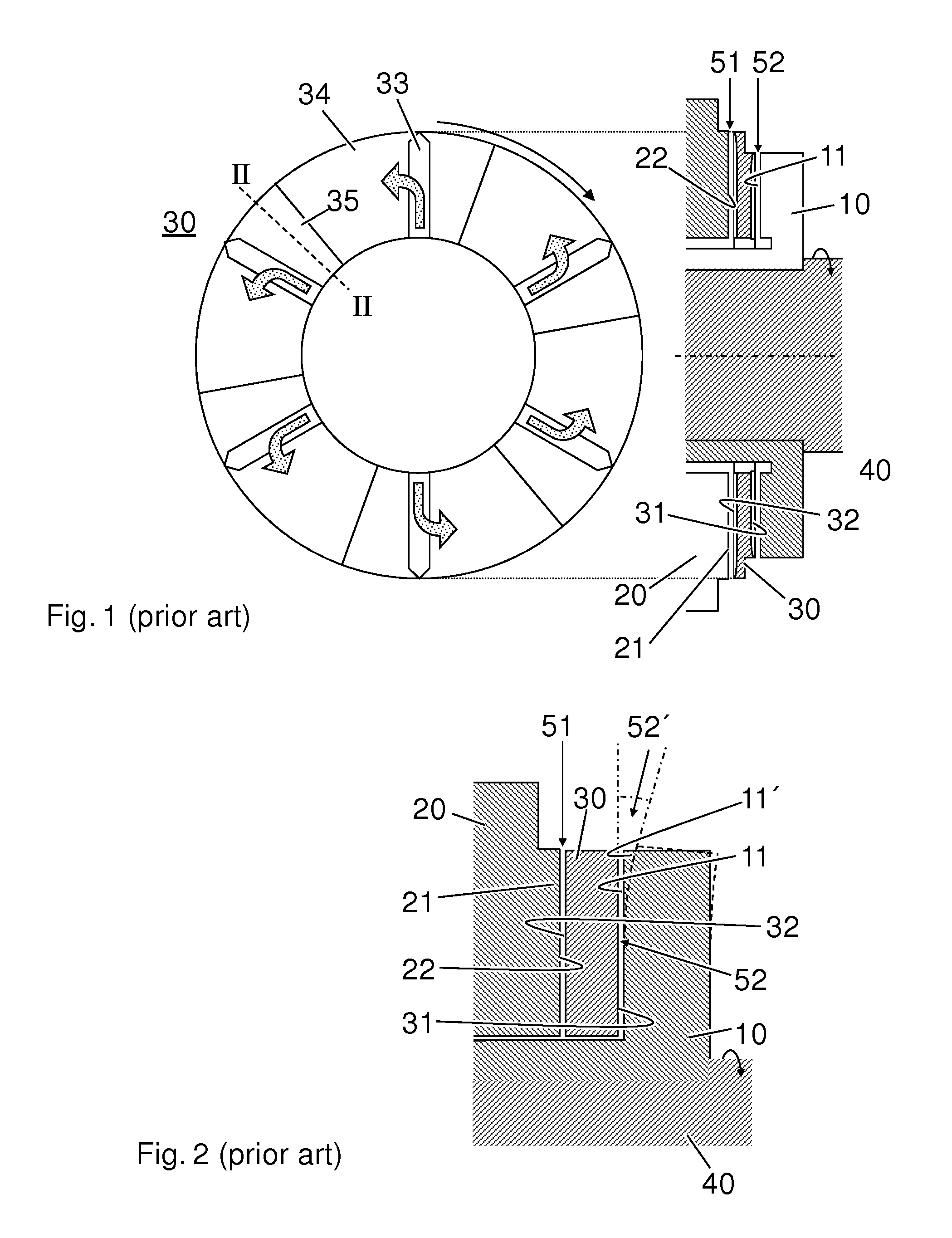

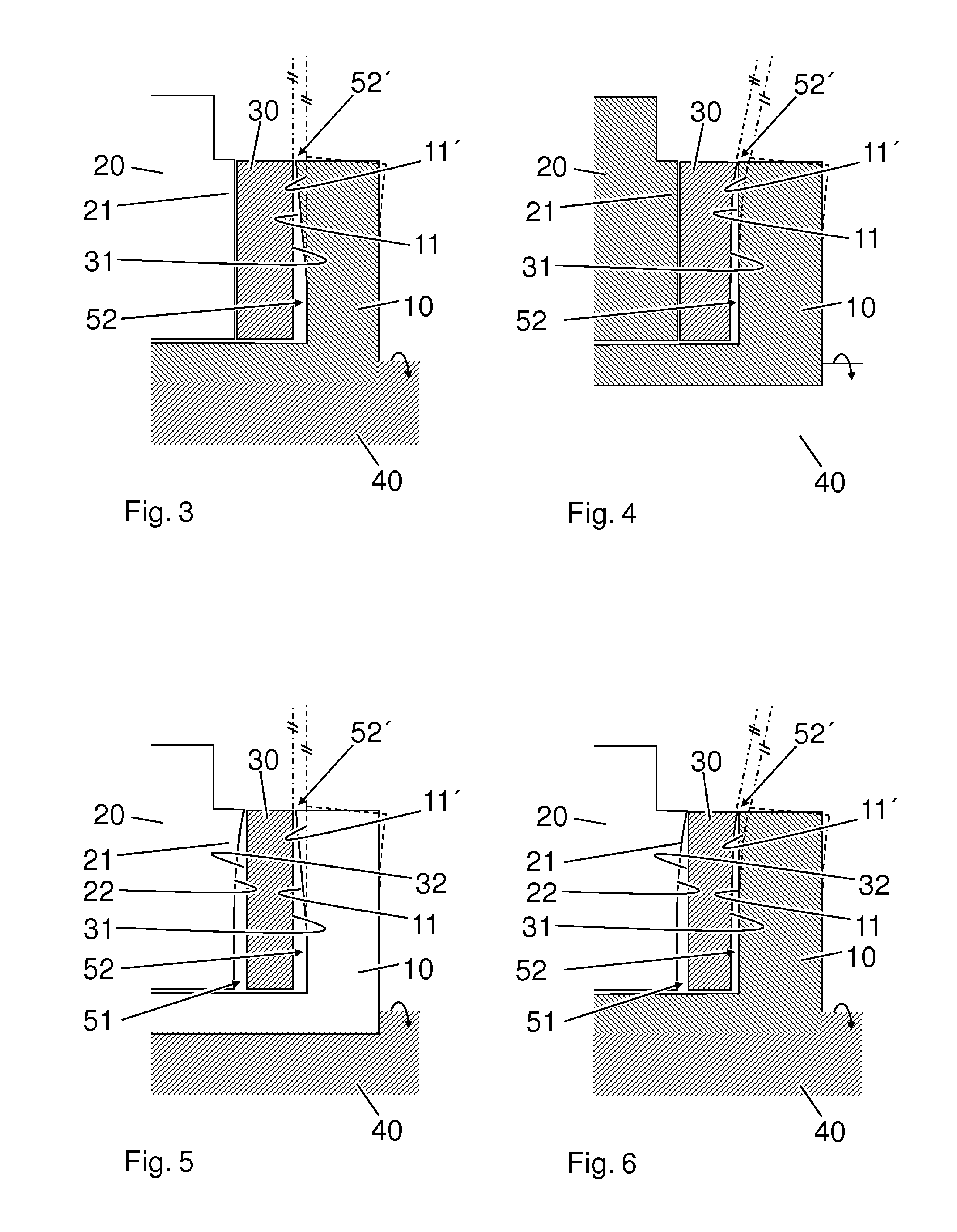

[0020]Exemplary embodiments of the disclosure can improve the load-bearing capability of a hydrodynamic axial bearing for mounting a shaft which is mounted rotatably in a bearing housing.

[0021]If the gap, which is formed between the load-bearing faces of the axial bearing, is configured so as to be constricted to the outside in the radial direction, by the load-bearing faces being arranged obliquely relative to one another at least in the radially outer region, a reduction in the relative oblique position of the load-bearing faces results during operation on account of the abovementioned deformation of the rotating load-bearing face. The constriction in the radially outer region is reduced, with the result that the load-bearing faces can rest more uniformly on one another during operation.

[0022]If, for example, the bearing comb is manufactured with a conical load-bearing face, that is to say a load-bearing face which is inclined toward the load-bearing face which lies opposite it, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com