Hard beads in steel to enhance strength

a technology of hard beads and steel, applied in the direction of heat treatment equipment, magnetic bodies, furnaces, etc., can solve the problems of significant increase in strength steel costs, and significant weight and cost reduction of parts, so as to achieve design and manufacturing flexibility, enhance strength, and increase weight and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]Reference now will be made in detail to the embodiments of the present invention, an example of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present invention by referring to figures.

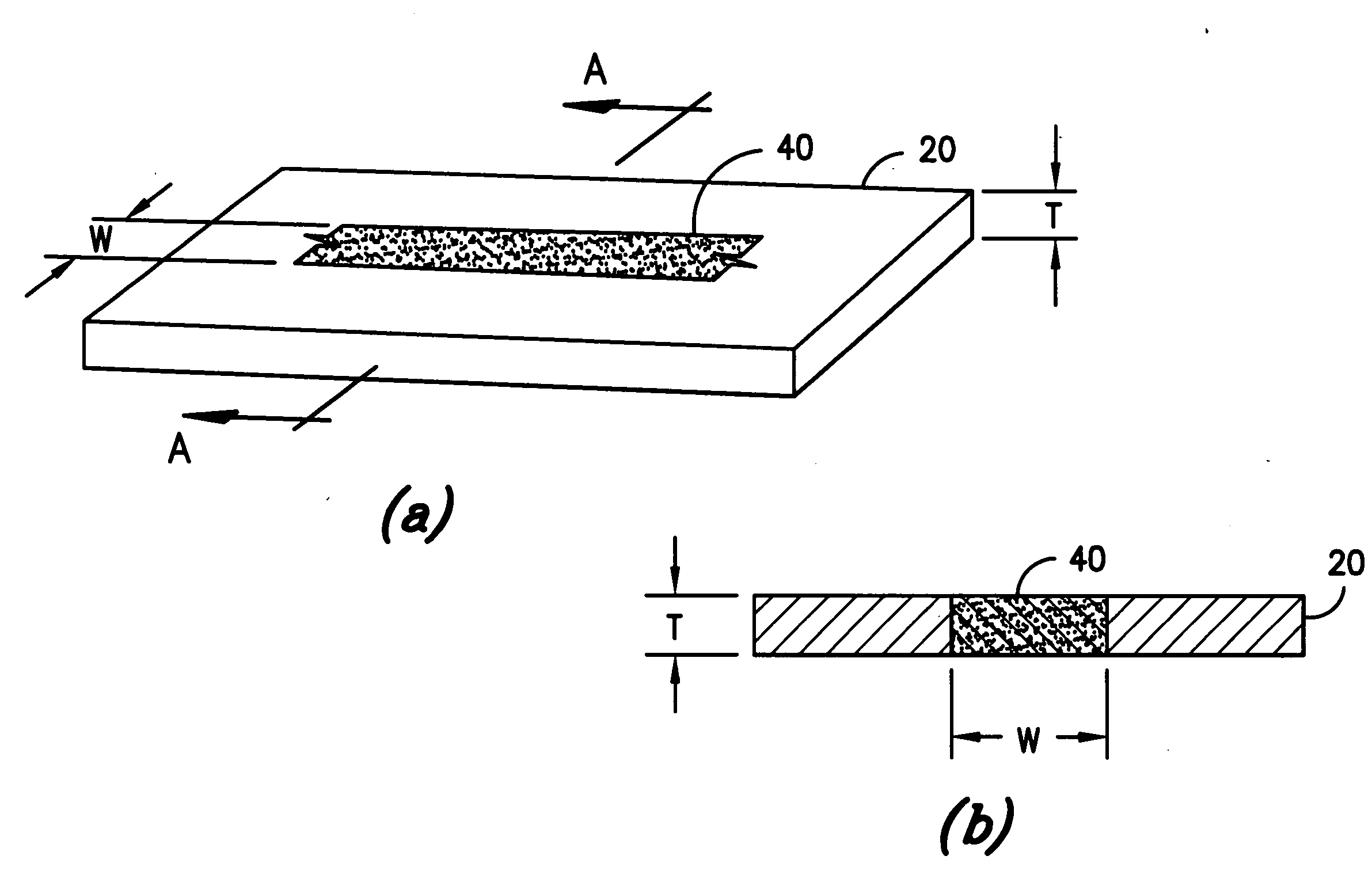

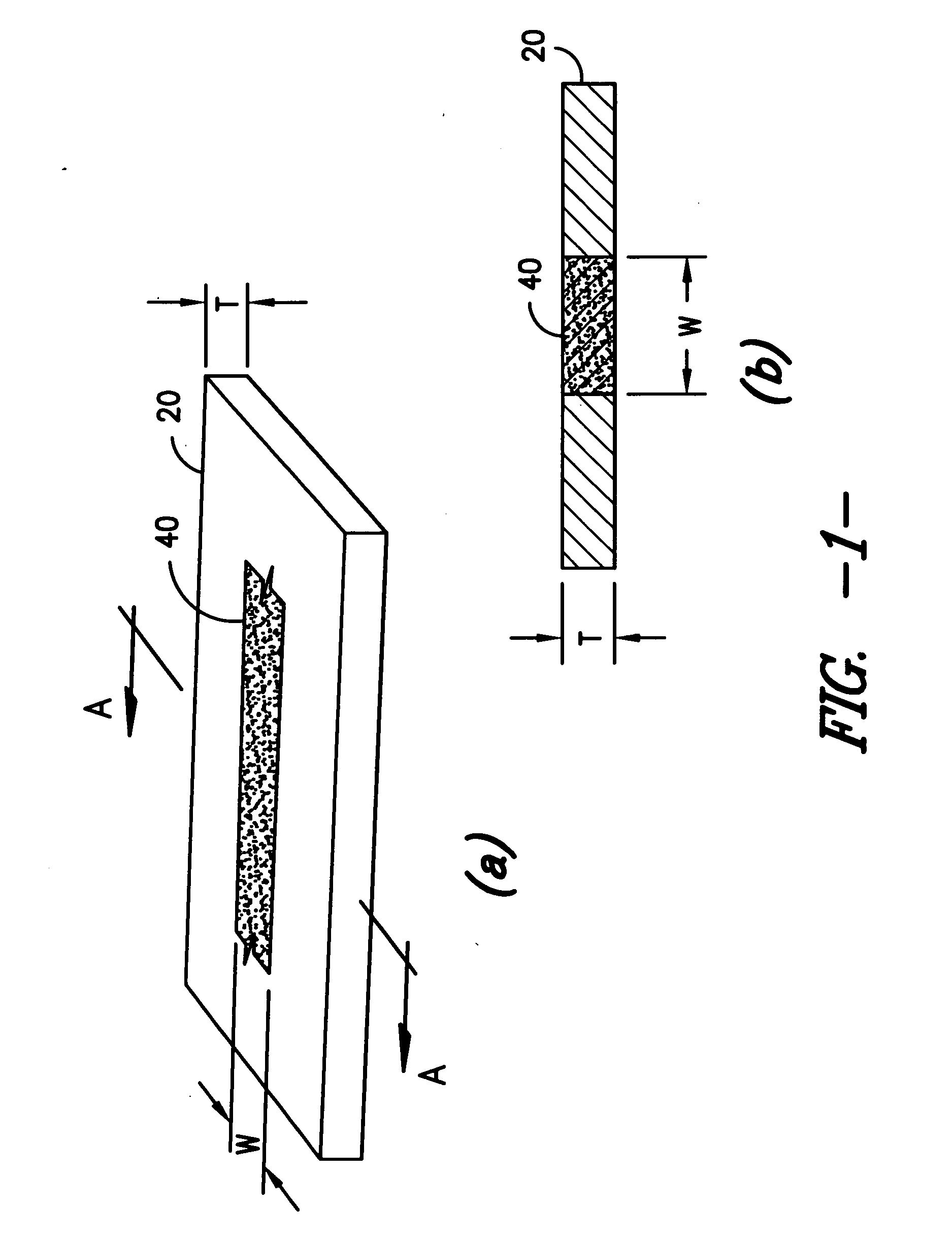

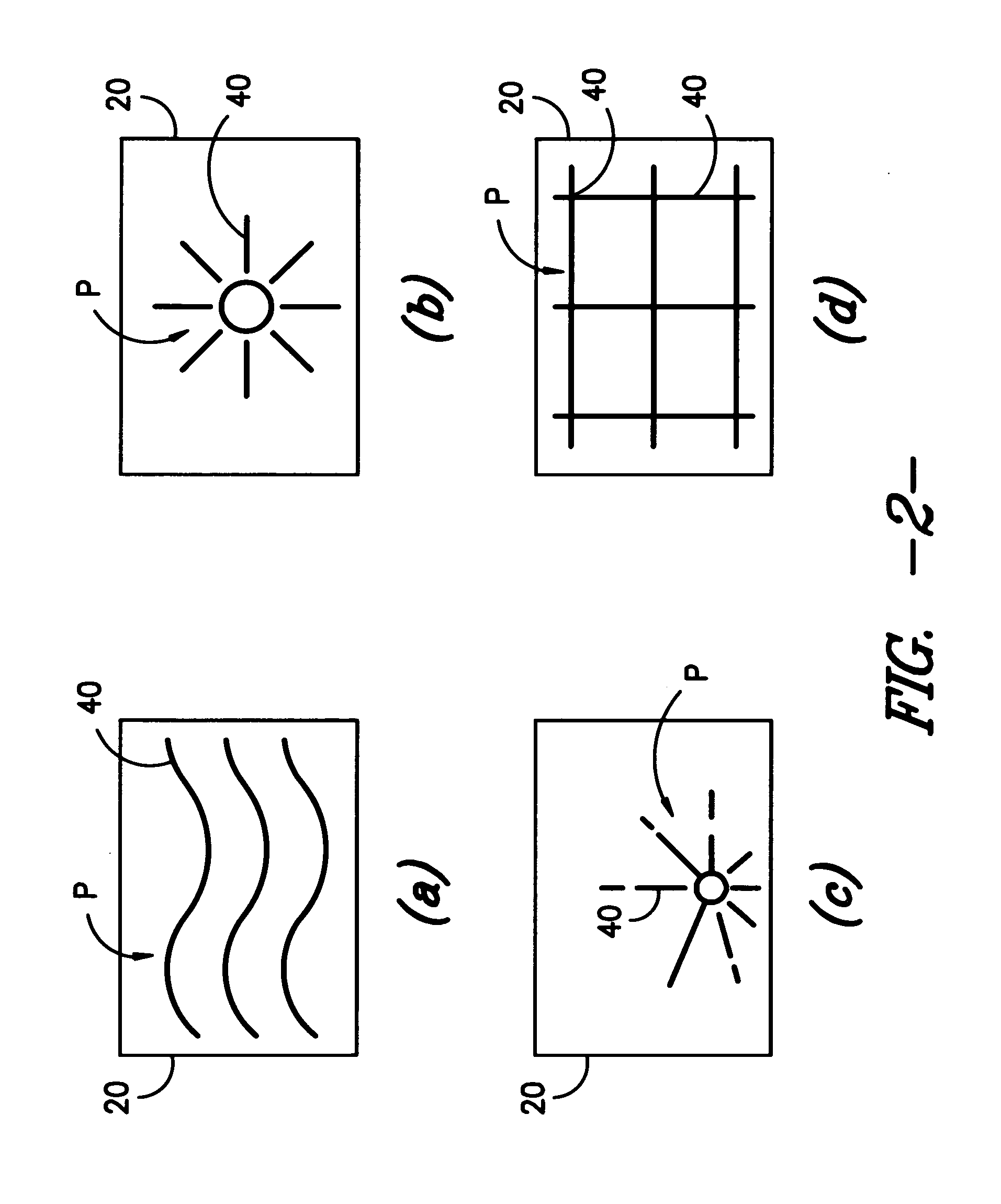

[0011]References are made to FIG. 1 as an example of hard bead 40 formed across the thickness of a single piece sheet 20 of steel (e.g. rolled steel). The hard bead 40 is formed to have an elongated shape extended in a surface direction in which tensile strength of the single piece sheet 20 is to be enhanced. The hard bead 40 is formed by melting and then quickly re-solidifying a selected zone of the single piece sheet 20. The steel in the selected zone can be melted by application of conventional technology; for example, by application of high energy laser beam, by application of high energy electron beam, by application of high temperature flame, etc. However, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com