Variable stroke length electrically operated diaphragm pump

a diaphragm pump and variable stroke technology, applied in the direction of pump control, positive displacement liquid engine, piston pump, etc., can solve the problems of inability to meet the needs of compressed air, etc., to achieve efficient energy conversion, eliminate the need for compressed air, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

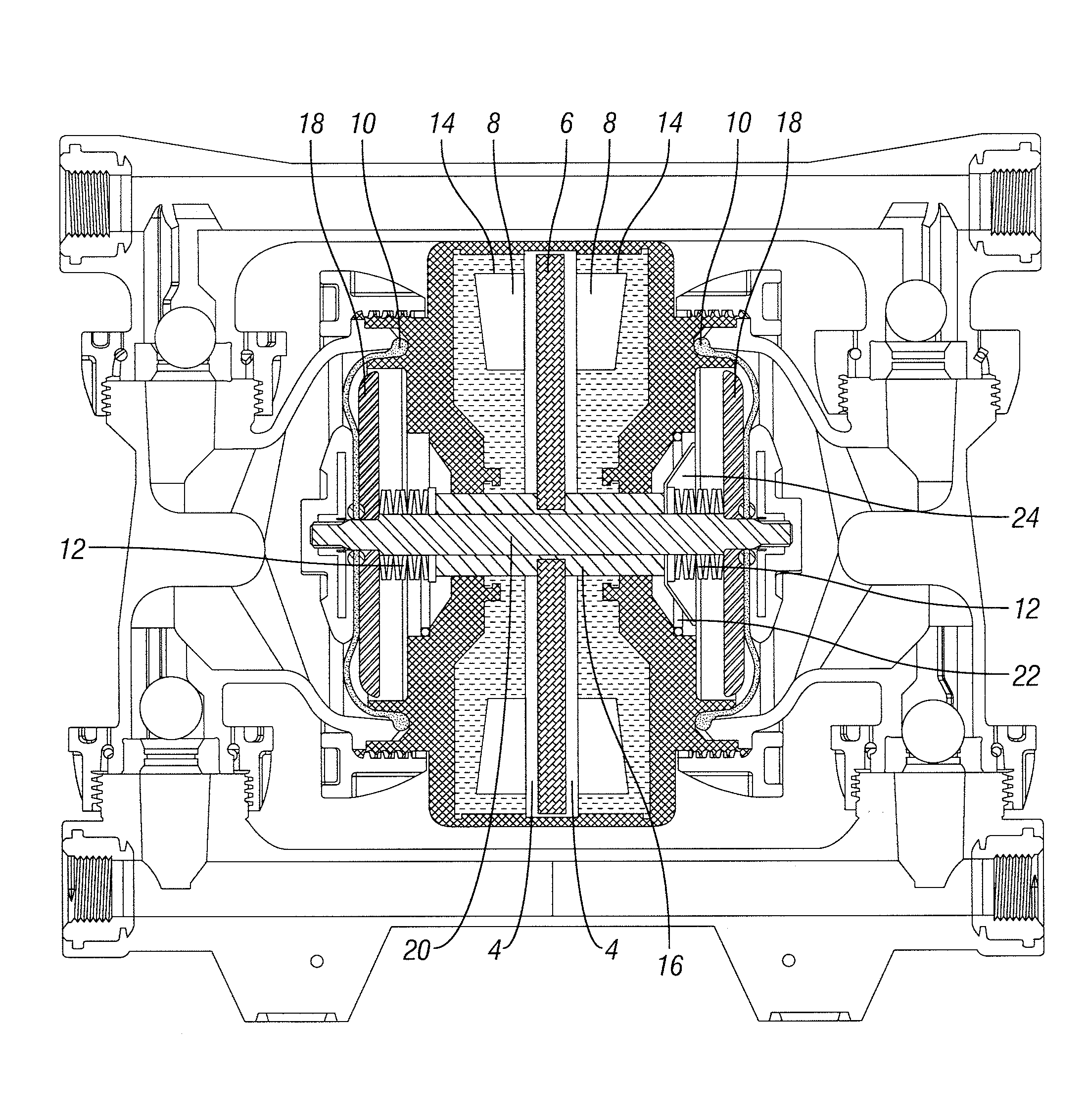

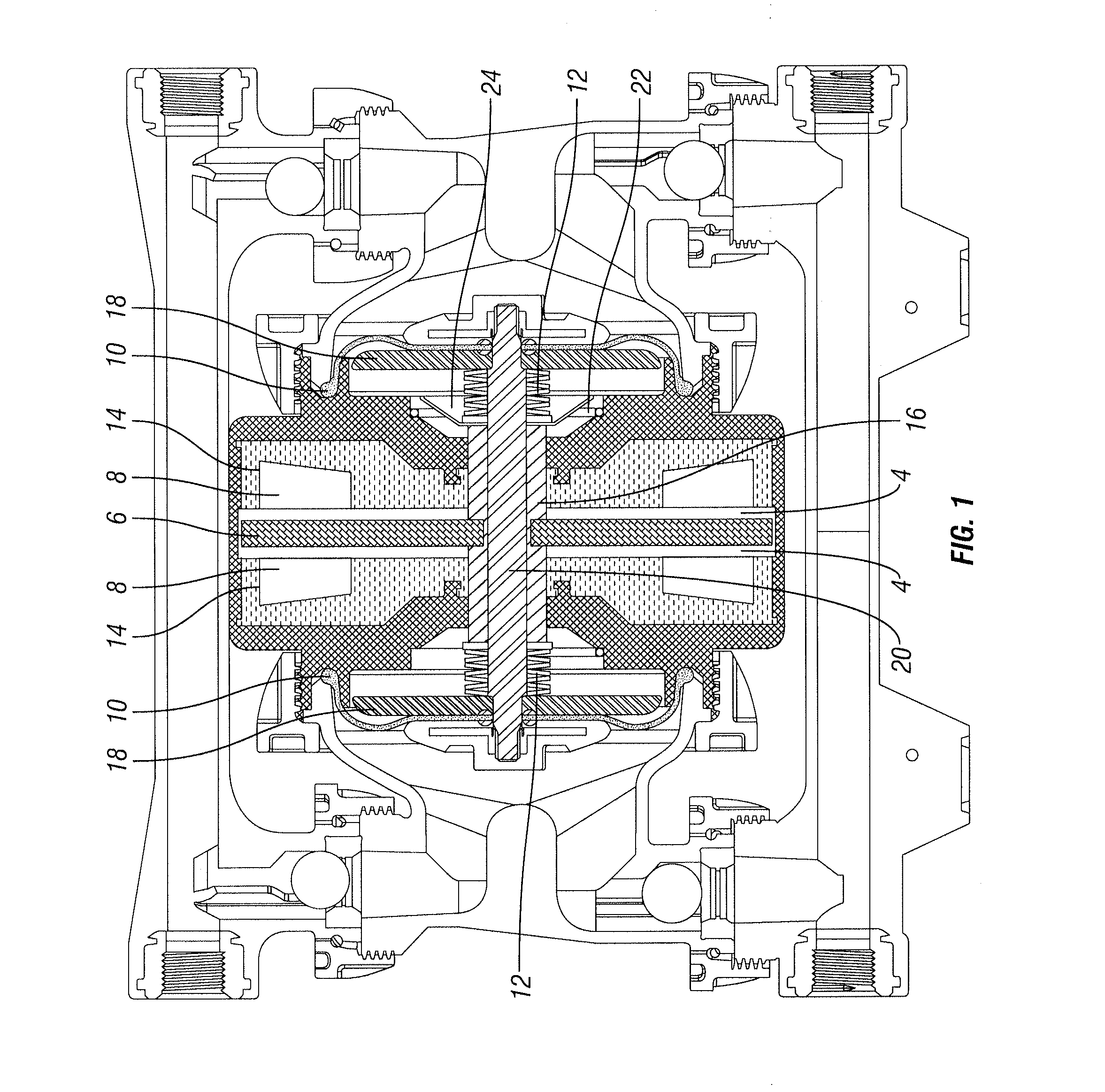

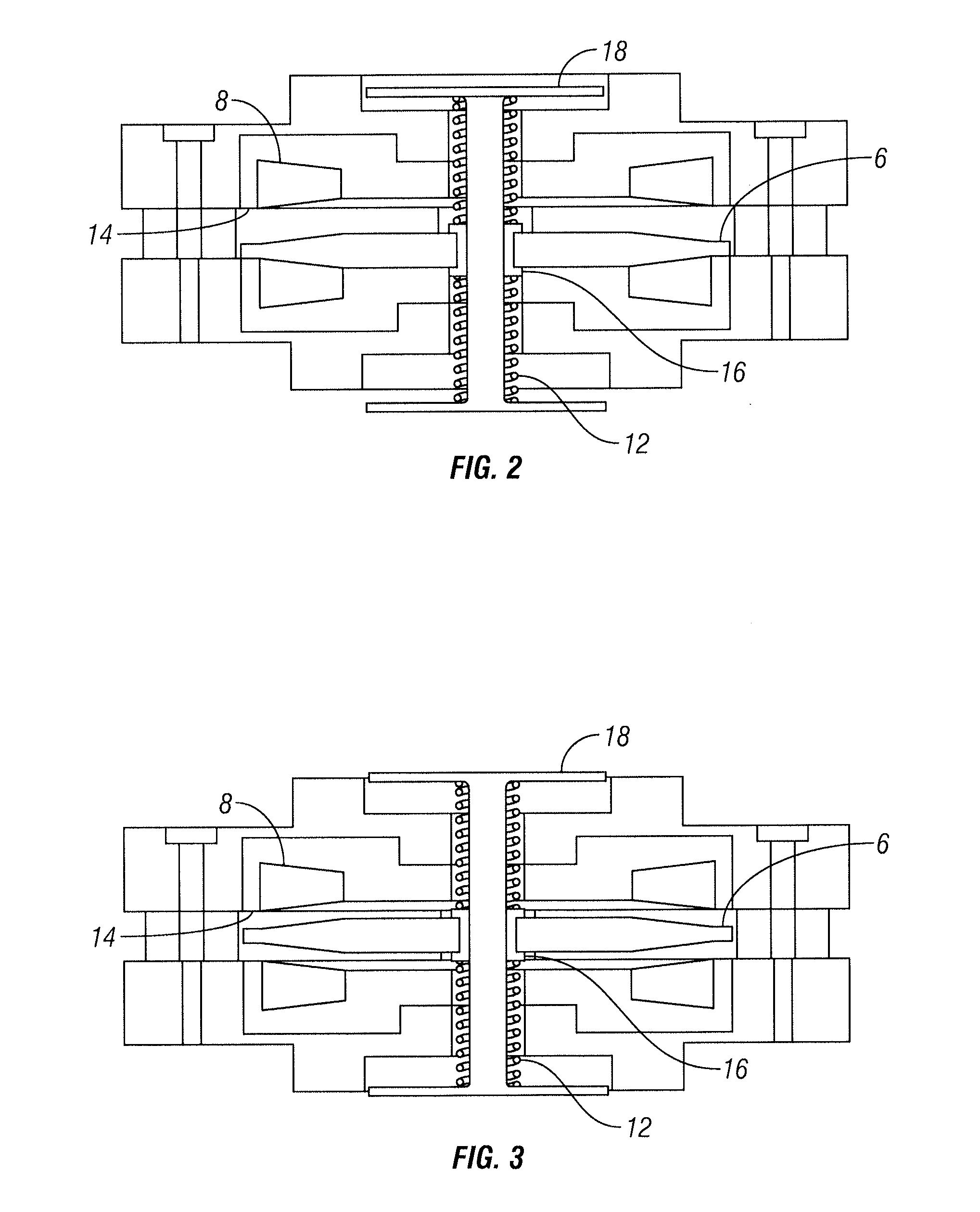

[0023]The present disclosure provides a variable stroke length EOD pump such as shown in FIG. 1. An illustrative embodiment includes a directly coupled EOD pump that employs axial air gaps 4 between its armature 6 and stators 14 so that no mechanical gear reduction is required to drive its diaphragms 10. The air gap distance is varied to assure that adequate axial force is attainable for the applied outlet restrictions. In an illustrative embodiment, a compression spring drive mechanism 12 allows relative motion between the EOD's armature 6 and pump diaphragms 10. The spring arrangement allows the magnetic air gap 4 to vary in response to the pump's outlet pressure so that high flow rates can be delivered into low restriction, and low flow rates can be delivered into high restrictions to replicate the operational performance of commercially available air operated diaphragm pumps.

[0024]The actuator of this EOD pump has air gaps between its moving and stationary parts oriented perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com