Slip resistant mat and method and system for making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

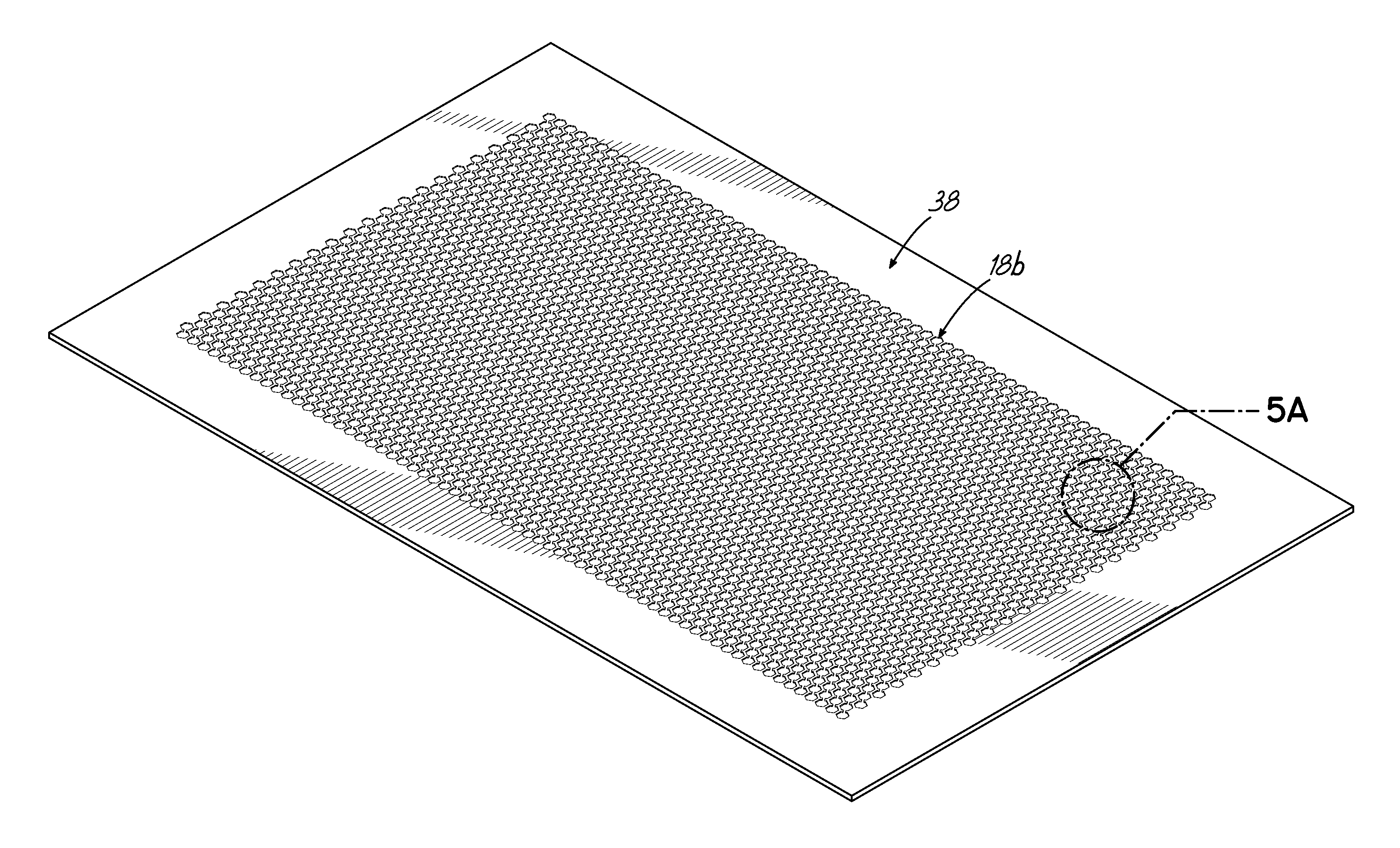

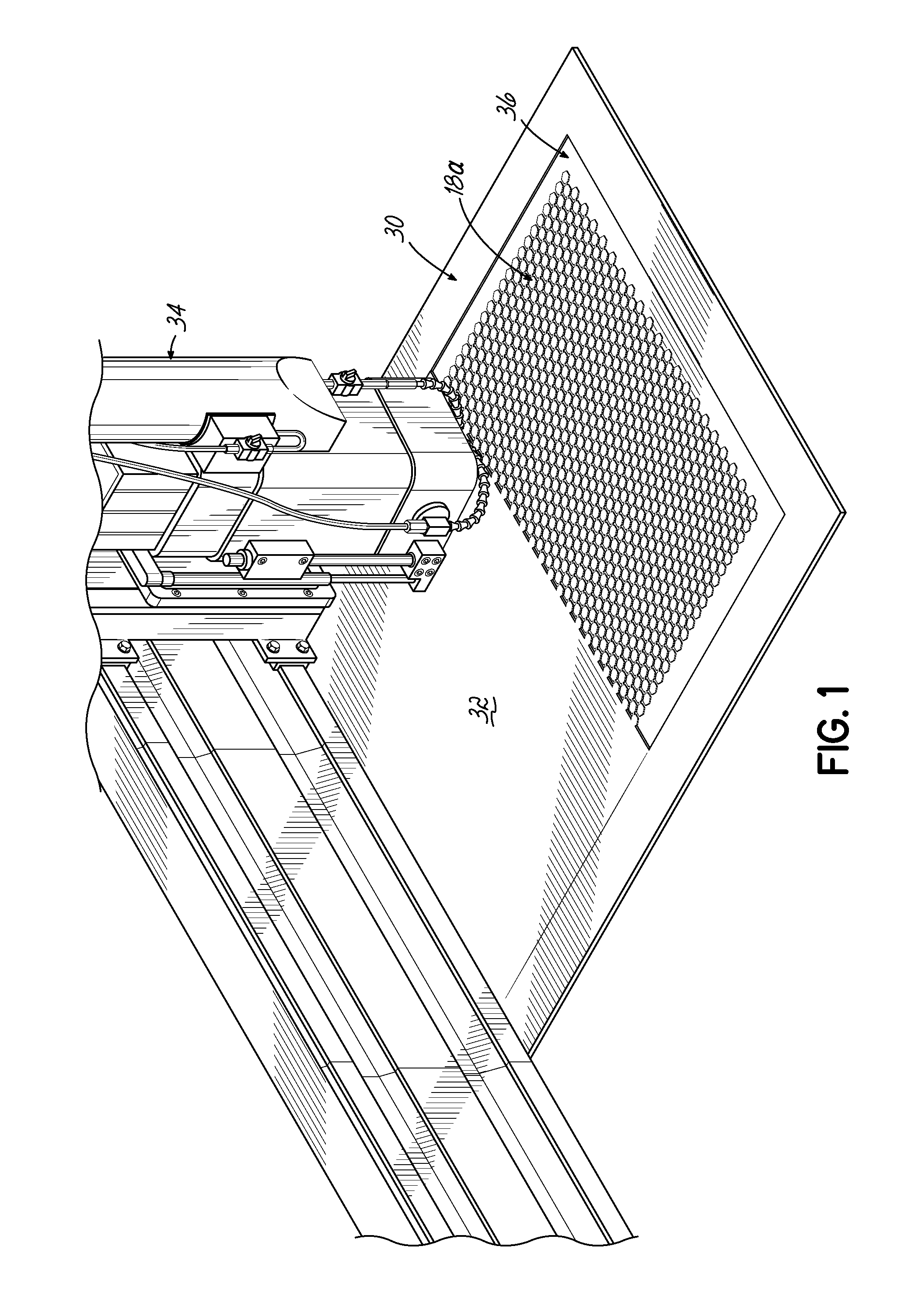

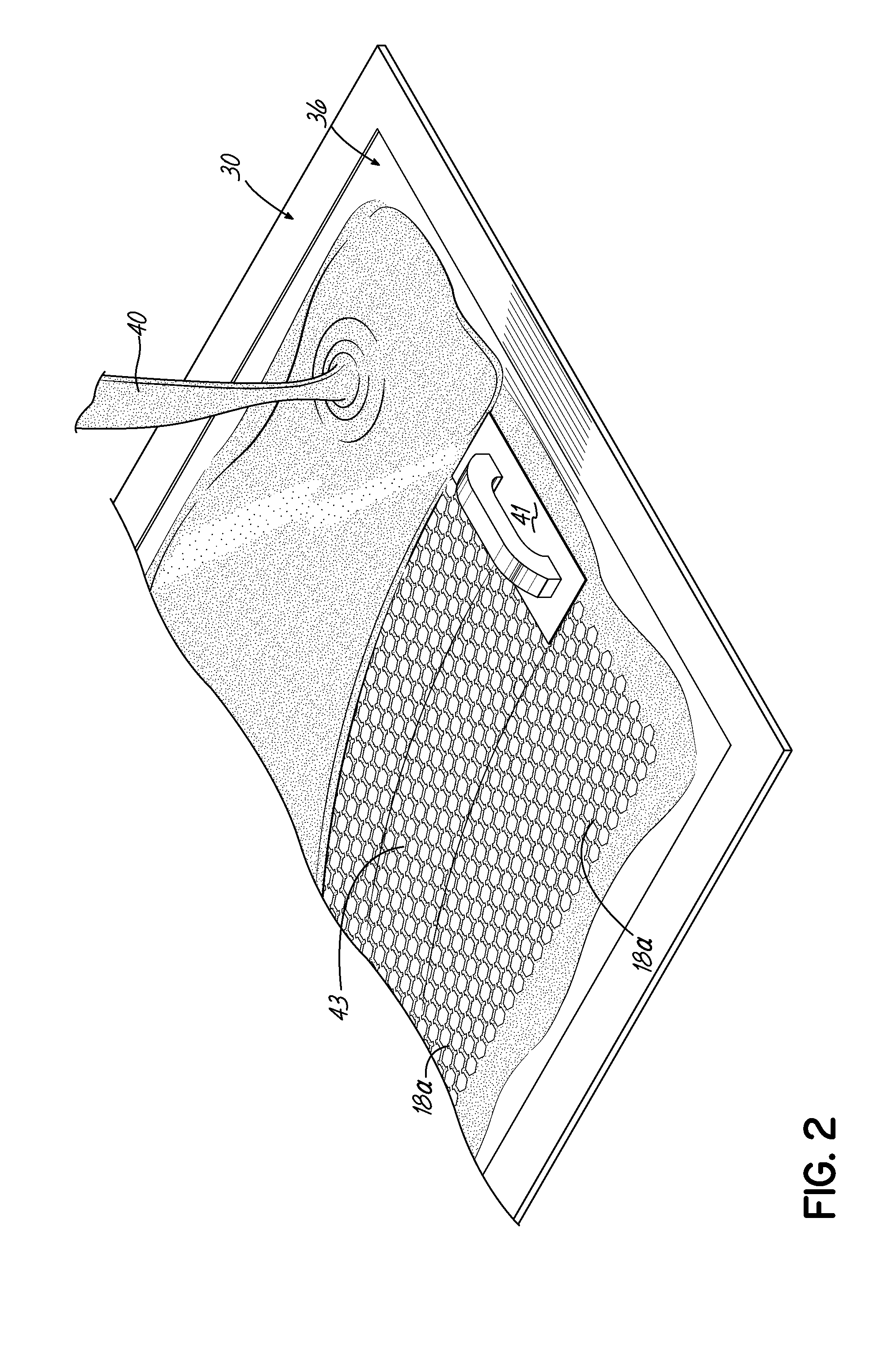

[0030]A slip resistant mat, system and method for making such a mat can include assembling parts with predetermined geometries to form a mold system that can be used for making slip resistant mats. The unique geometries of the parts which form the mold system can be manufactured efficiently, robustly and with reduced cost. The mold system of this invention can be used to make slip resistant mats with increased surface area contact between a backing of the mat and the floor. This can be a particularly advantageous feature to overcome residual moisture trapped between the mat backing and the floor to provide resistance to the mat from slipping.

[0031]Exemplary embodiments of this invention will be described with reference to the drawings and figures in which like numerals represent like elements throughout the several figures. Referring now to FIG. 6 which illustrates a perspective view of an exemplary slip resistant mat 10 according to one embodiment of this invention. The exemplary s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com