Three-part closure sealing and dispensing device for all types of Containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

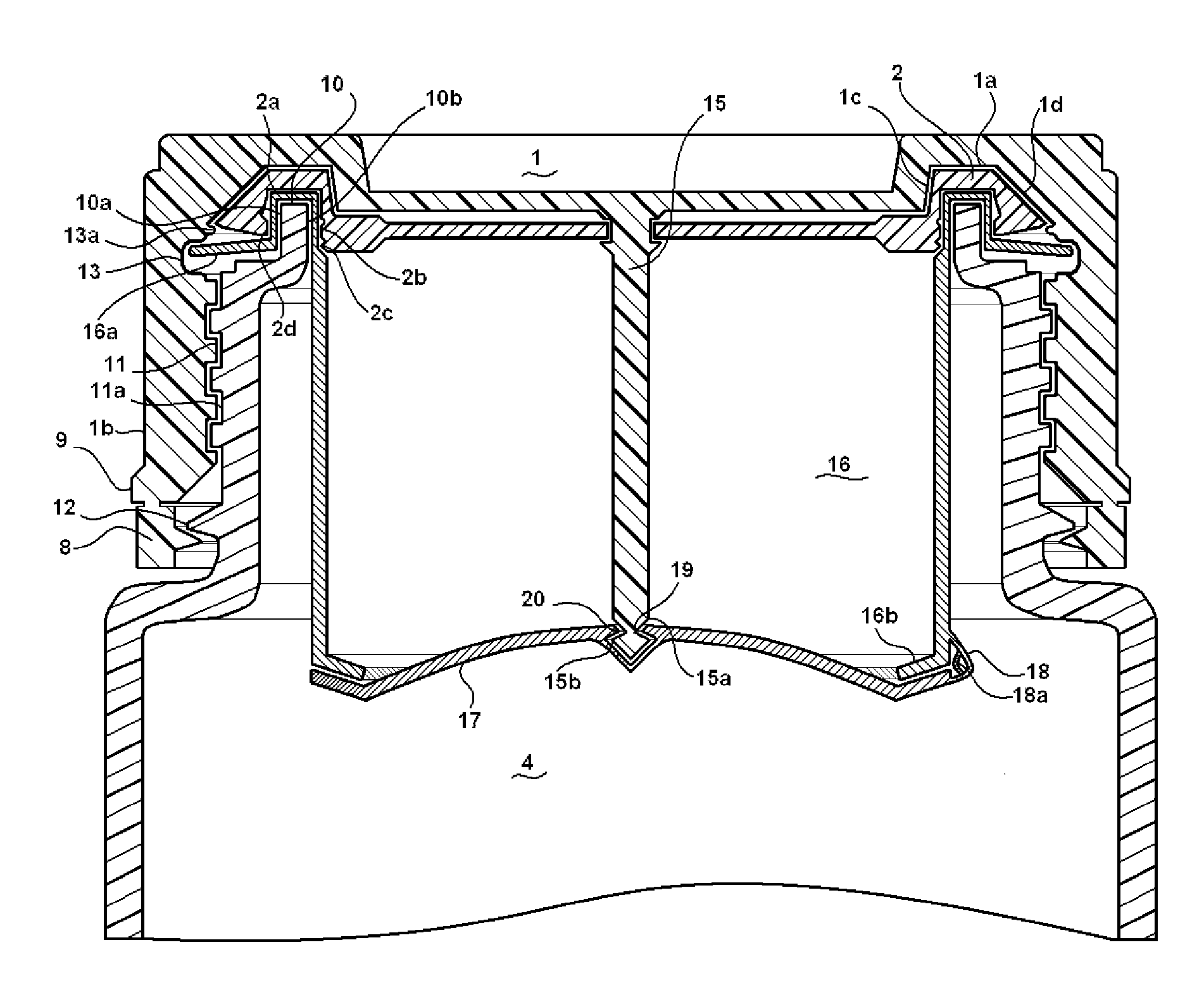

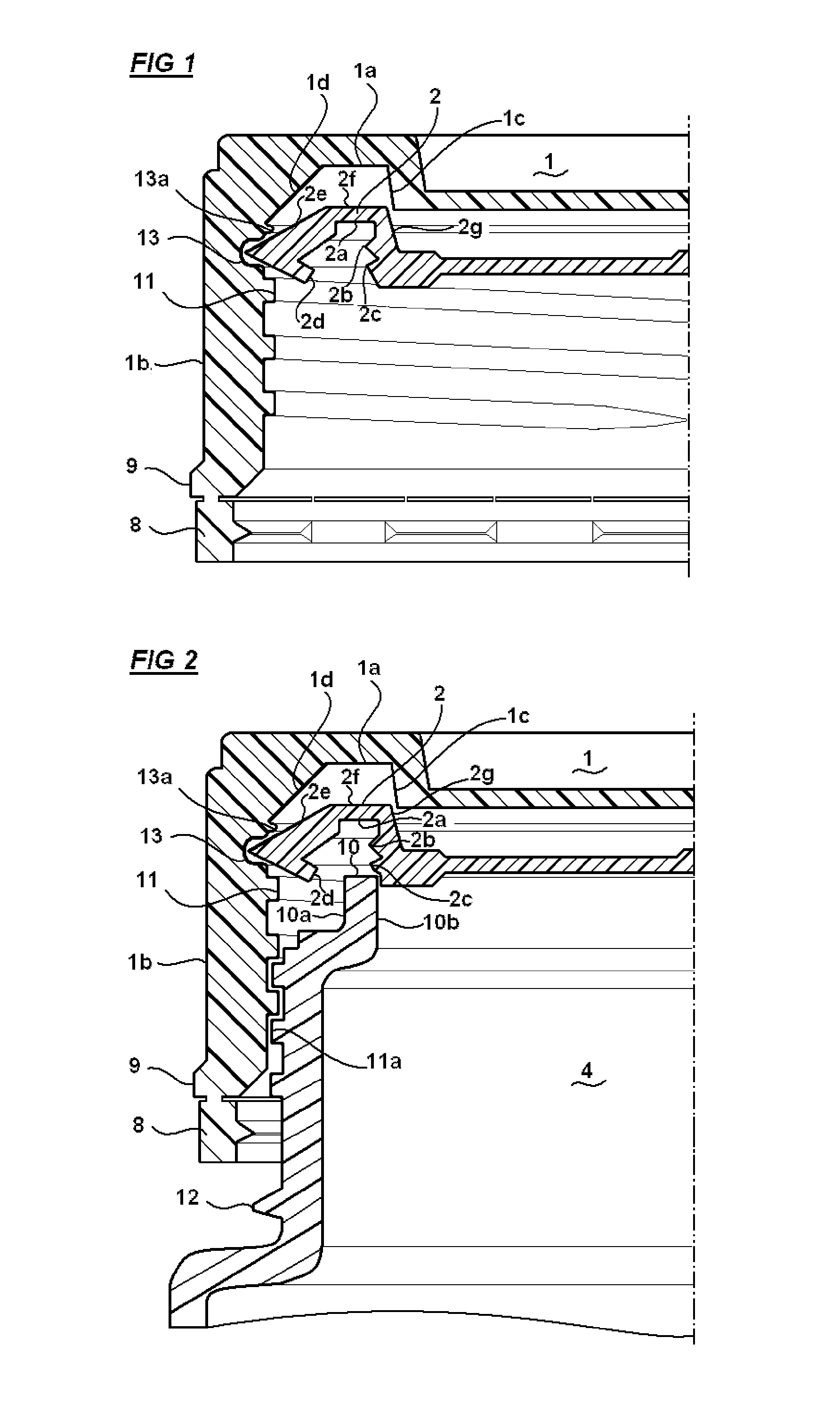

[0055]Referring to FIGS. 45 and 6 illustrates the invention, this embodiment is similar to that shown in FIGS. 12 and 3 and illustrates the invention in which a container closure body 1 defined by a inside top wall rim 1a and a cylindrical outside wall 1b and inner rim angle side wall 1c the container has a sealing spout top lip 10 and a sealing outer spout wall 10a with a sealing inner spout wall 10b and external threads that the closure is held onto the container by, except where the three-dimensional flexible sealing wad 2 has been completely inserted into the underneath top portion of the closure body 1 and is formed in such a way as to engage the container 4 when the closure 1 is threaded onto the container neck, by in turn forcing the flexible sealing wad fingers 2a 2b 2c and 2d to flex when coming into contact with all three sealing spout wall's 1010a and 10b of the container 4 through in turn torque up further the closure 1 applying increasing pressure to compress and sandwi...

third embodiment

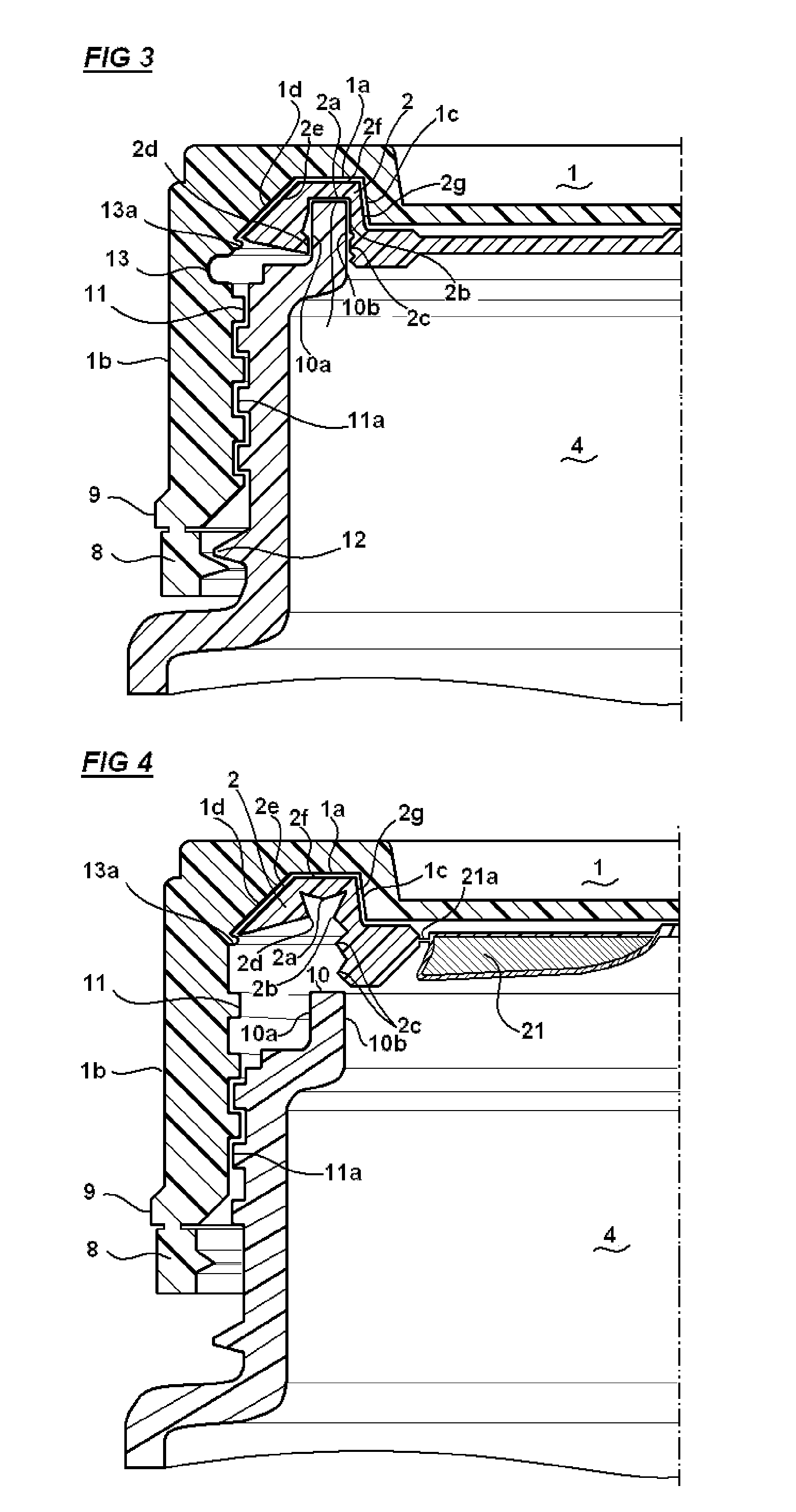

[0060]Referring to the drawings, FIGS. 78 and 9 this illustrates of the invention in which is similar to that shown in FIGS. 45 and 6, except that the three-dimensional flexible sealing wad 2 has been formed with an aluminum induction sealing foil lamination 3 to the underneath side of the sealing wad 2 or coated with a heat activation substance which can be bonded through either induction seal methods or activated by heat or hot steam at the time of the packaging process.

[0061]The child resistant tamper-proof evident security feature has been formed in the same way by creating a recess groove 21a which runs around the outer top surface of the inside perimeter edge of the sealing wad 2 formed in such a way to create a weakened indentation rip line created at the time of molding the seal 2 through knife cutting partially into the top groove 21a side only of the sealing wad foam 2 but not cut all the way through to weaken or cause damage to the aluminium induction film seal 3 thus pro...

fourth embodiment

[0066]Referring to FIGS. 1011 and 12 this illustration shows the invention the closure of this embodiment is designed particularly for use on a plastic or glass container having a threaded neck which is consistently out of round or formed severely out of shape through the manufacturing process, such as a beverage bottle or glass jar for example. The closure comprises of single flat flexible sealing wad foam material laminated with a protected film to protect the foam seal, or can be laminated with an aluminum peel-able induction sealing film which can easily be removed with or without the seal wad still being attached.

[0067]In this cross-section elevational view shows the flat one piece flexible compression sealing wad 5 is assembled into the closure 1 the seal fits into a large oversize recess groove 13 provided in the inside wall edge of the closure body 1, which allows the over size flexible seal wad 5 to stay fully expanded in a relaxed position with large tolerances so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com