Vacuum Truck with Loading Pump

a technology of vacuum trucks and loading pumps, which is applied in the field of vacuum trucks with loading pumps, can solve the problems of increasing the administrative burden of attendant costs, the possibility of the same type of undesirable vapors from the products, and the significant cost of monitoring, scrubbing and containing those emissions,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

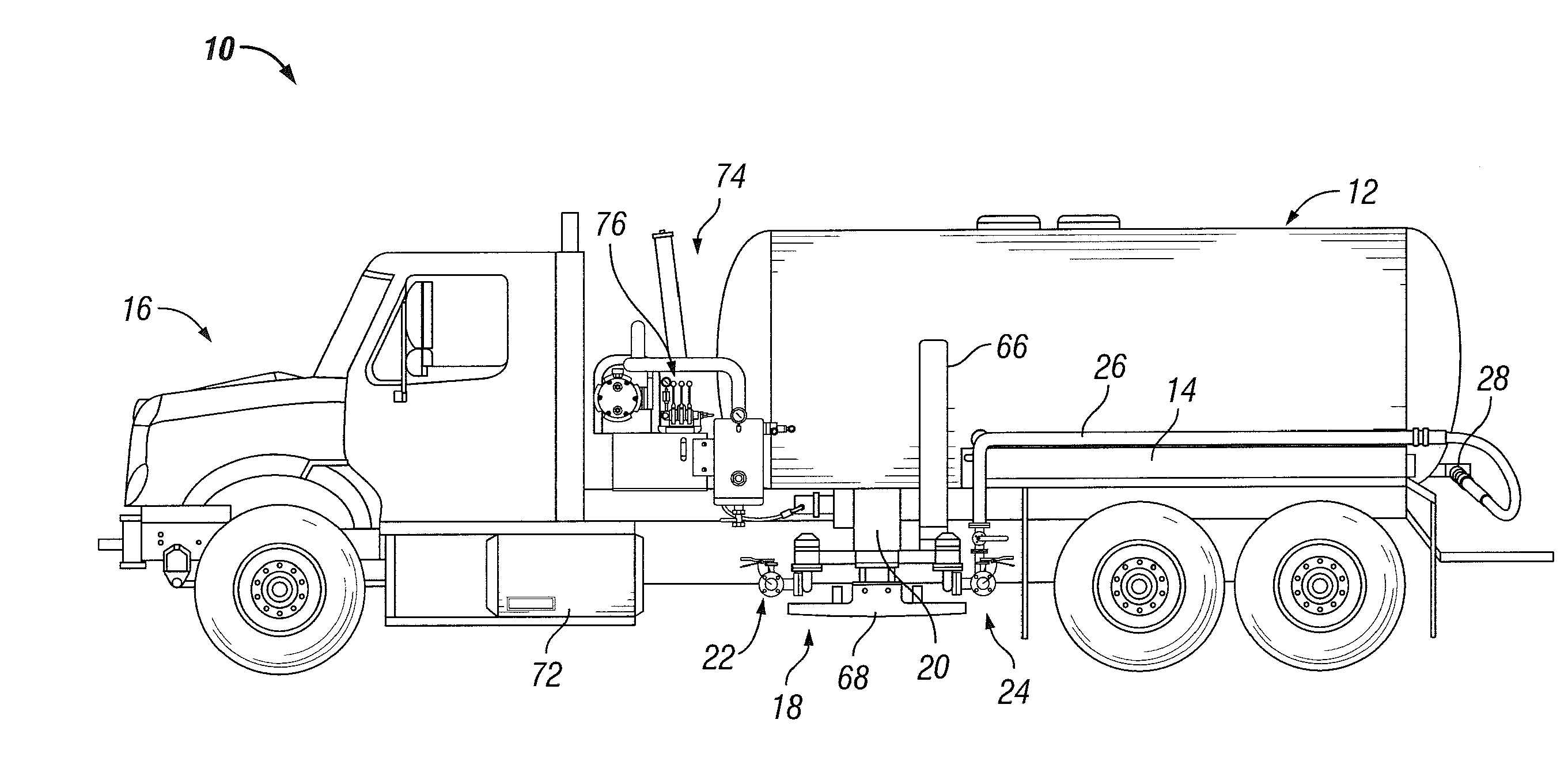

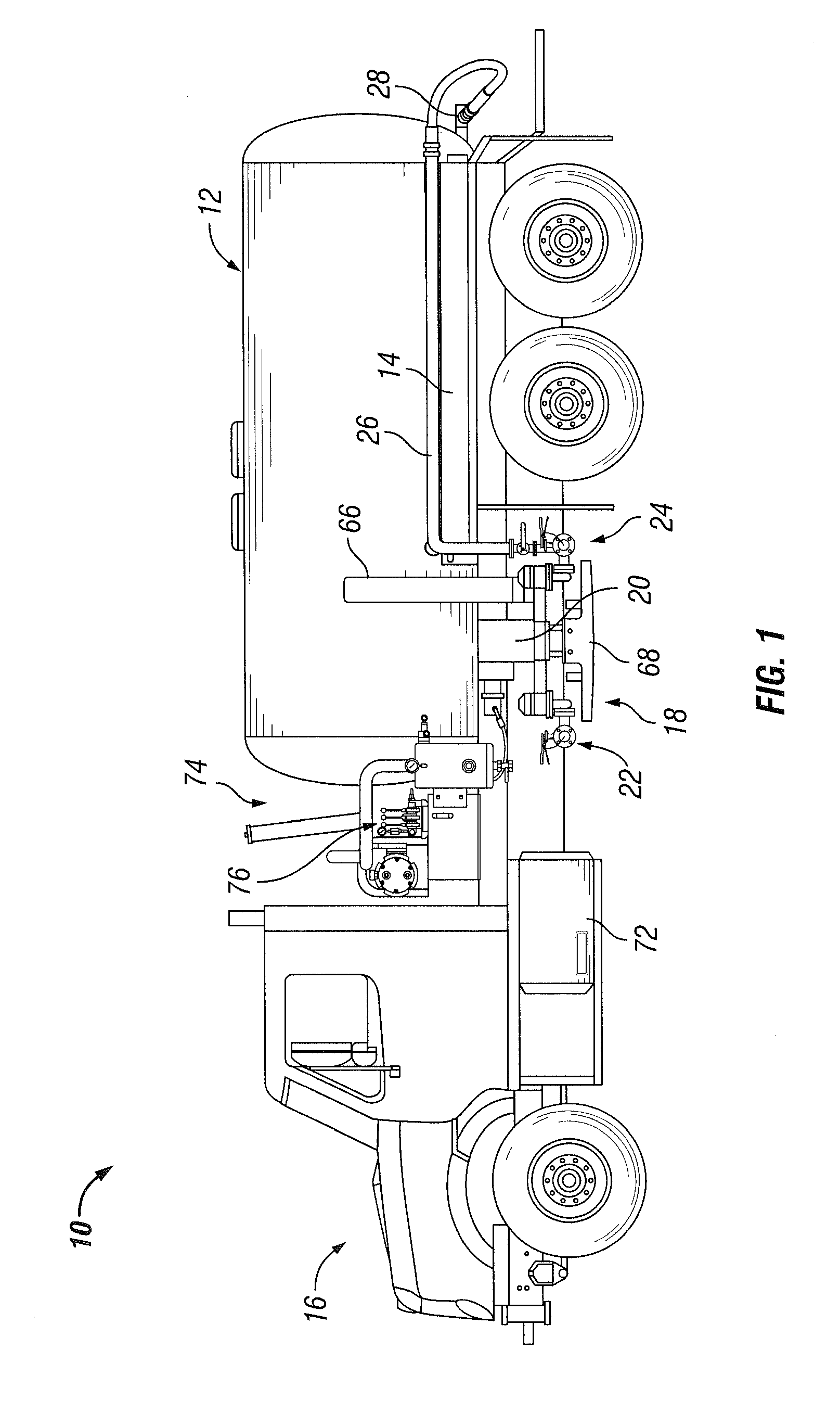

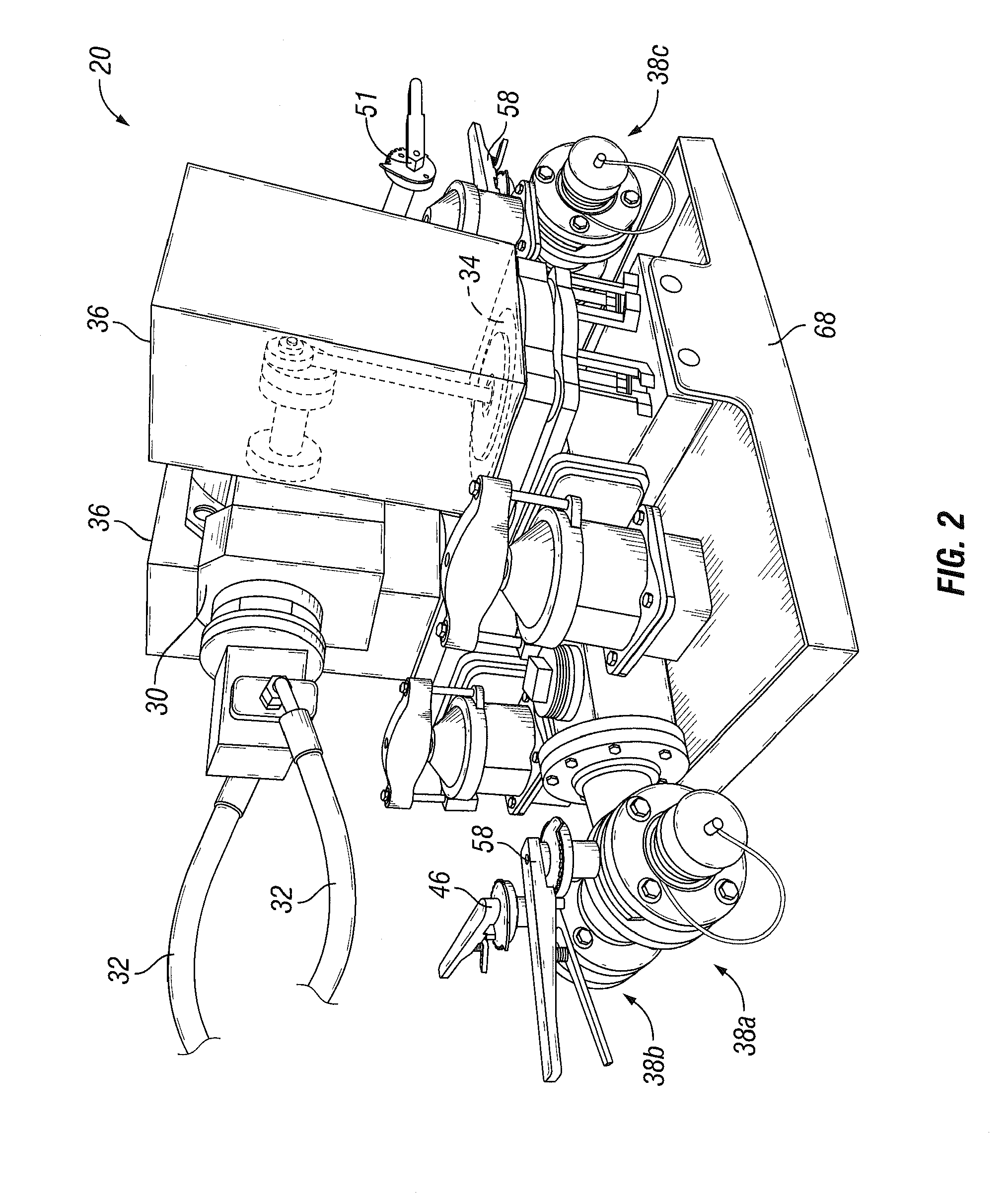

[0018]In the drawings, there is provided a fluid transport truck 10 according to the present invention for loading, transporting, and unloading waste fluids. For purposes of this application, waste fluids can include fluids containing volatile organic compounds (VOC), petrochemical or other waste products, sludge, wastewater, hazardous or malodourous material, or any material objectionable because of the presence of petrochemicals, odor, or other undesirable vapors during loading or unloading, including fluids subject to regulations at the Federal or state level. The products include any type of fluid which is required to be treated because of environmental concerns, special handling requirements, or other reasons. As used herein, fluid means vapors, gases, liquids, sludges, semi-solids, or anything else that can flow through a pipe. The transport truck 10 has a storage tank 12 mounted on a chassis bed or frame 14, and a motor 16 furnishing transport power to move the truck 10.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com