Labeler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

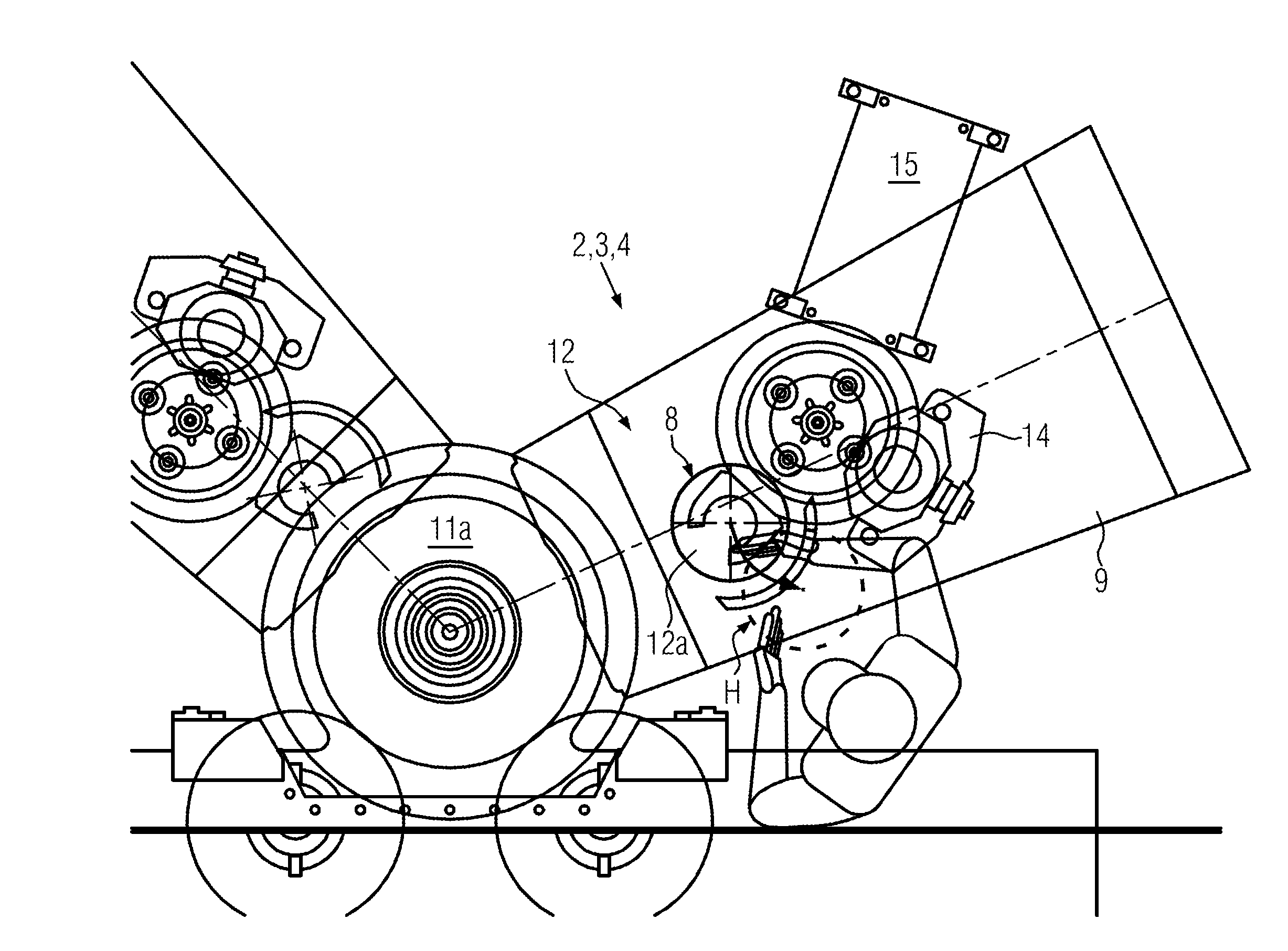

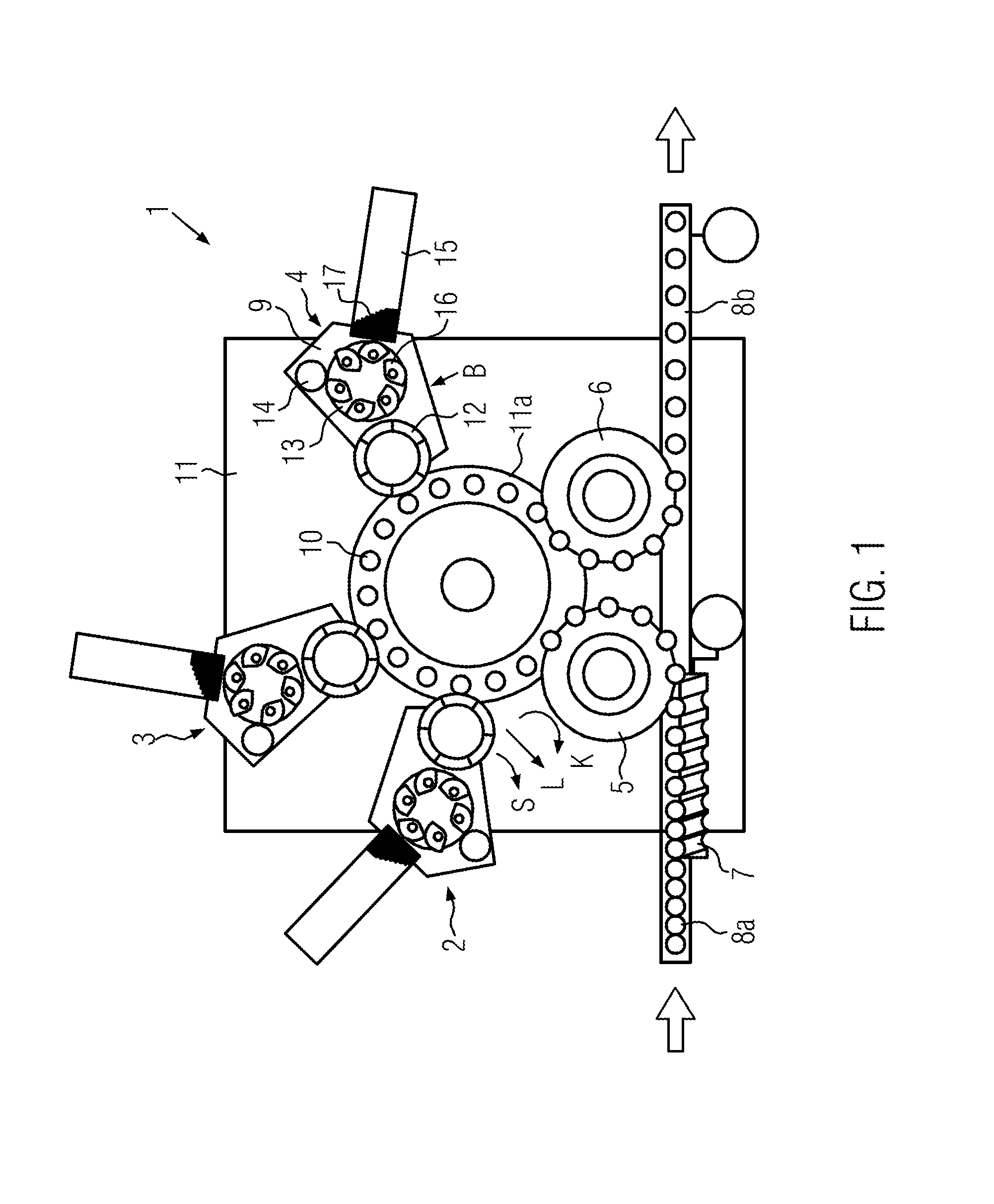

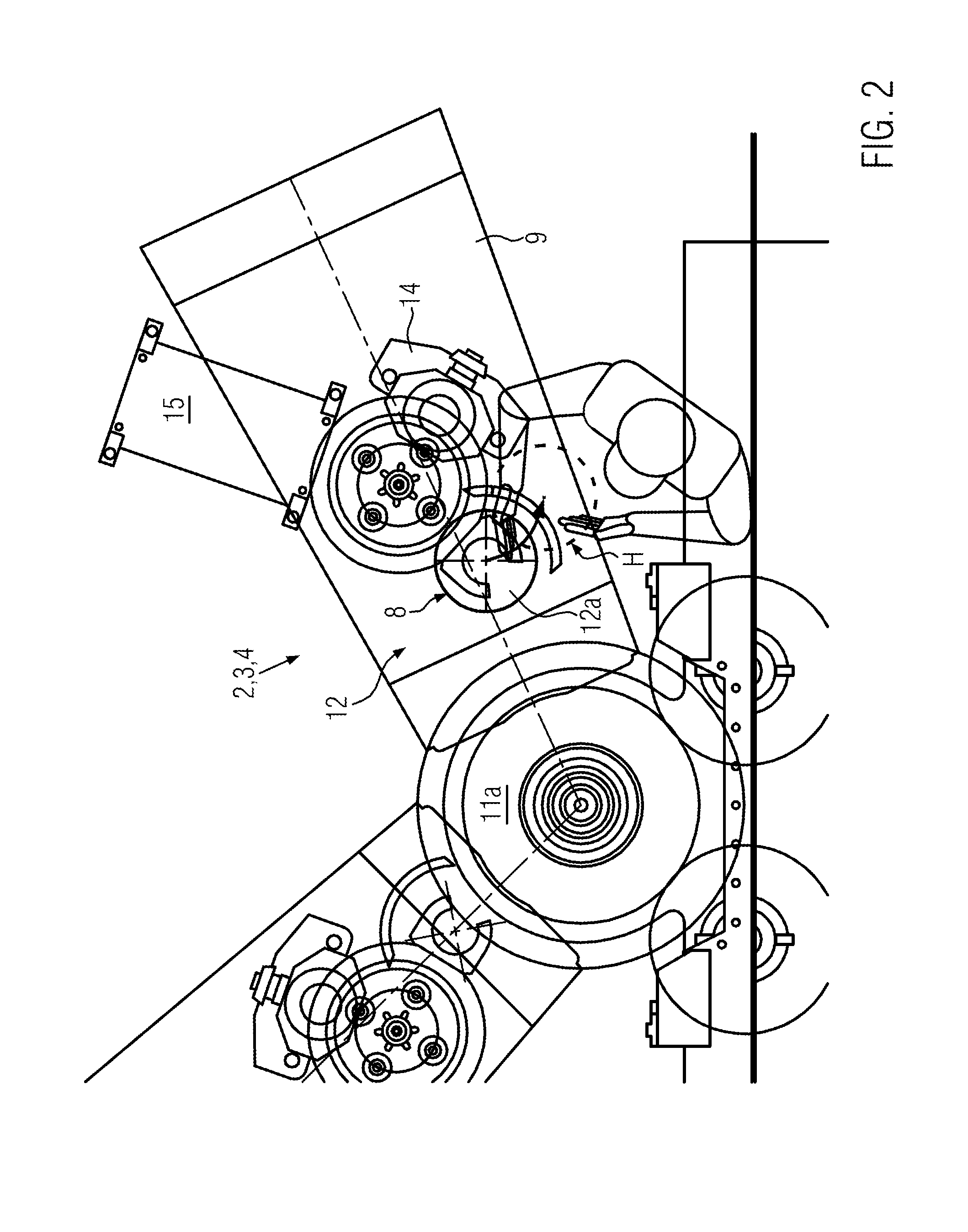

[0015]FIGS. 1 to 3 show in a highly schematic representation a labeling machine 1 comprising a table plate 11, which is supported by a lower frame and on which a rotary table 11a, an infeed star wheel 5 and a discharge star wheel 6 are rotatably supported. A separating screw 7, which is oriented parallel to a conveyor belt 8a, is arranged upstream of the infeed star wheel 5, and an additional conveyor belt 8b is arranged downstream of the discharge star wheel 6. The conveyor belts 8a, 8b, the separating screw 7, the infeed and discharge star wheels 5, 6 as well as the rotary table 11a serve to convey containers 10, the containers shown here being bottles, past at least one labeler 2, 3, 4. In the embodiment shown, three such labelers having substantially identical structural designs are provided.

[0016]Each labeler 2, 3, 4 comprises an assembly housing 9, which is positioned on the table plate 11. The normal components of such labelers are arranged on the top of the assembly housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com