Asphalt brick device and method of making same

a technology of asphalt bricks and bricks, which is applied in the direction of roads, climate change adaptation, construction, etc., can solve the problems of asphalt surfaces such as roads, driveways and parking lots, present annoyances, and costly hazards, and achieve the effects of reducing the safety of drivers, and reducing the risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

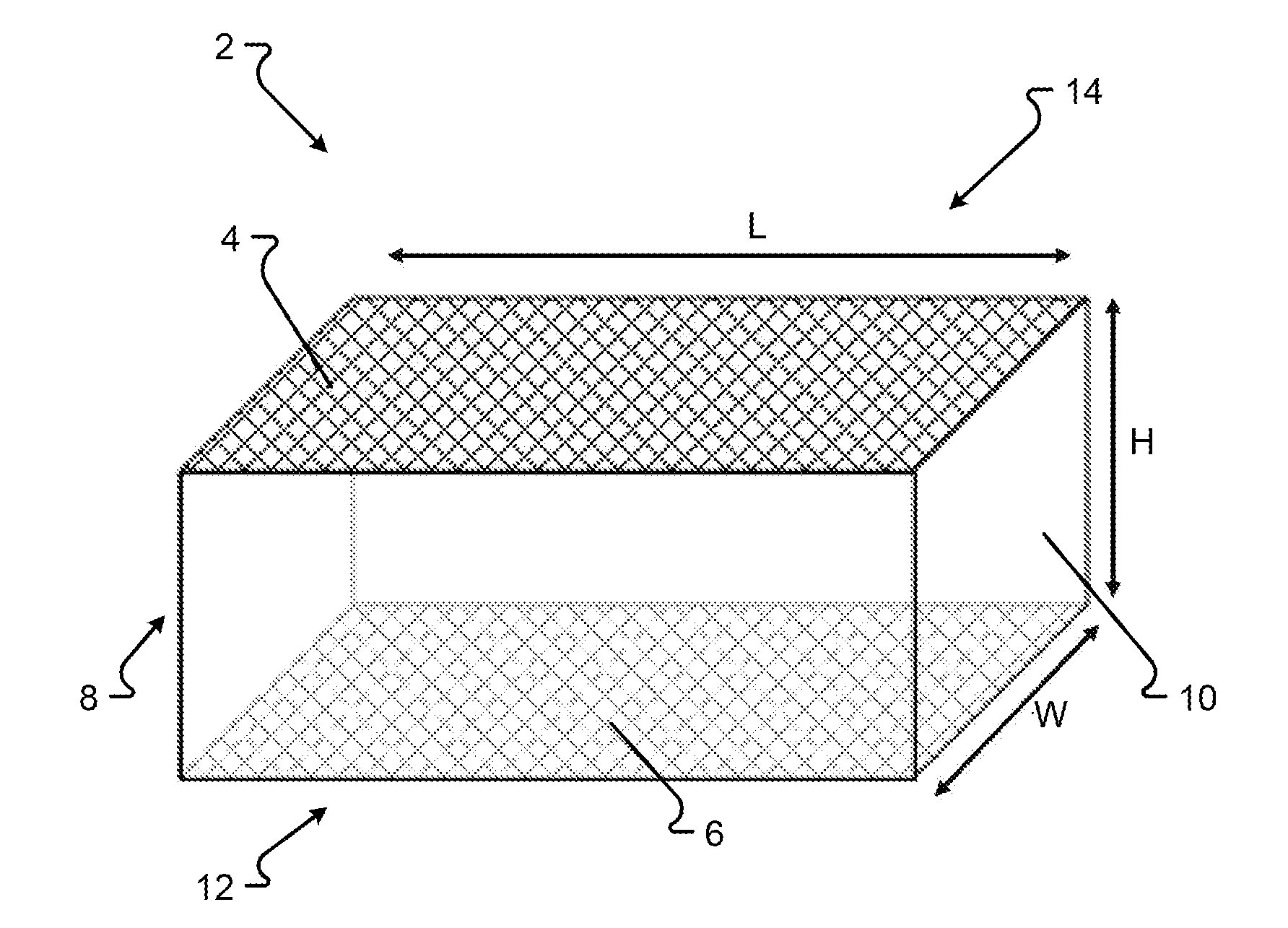

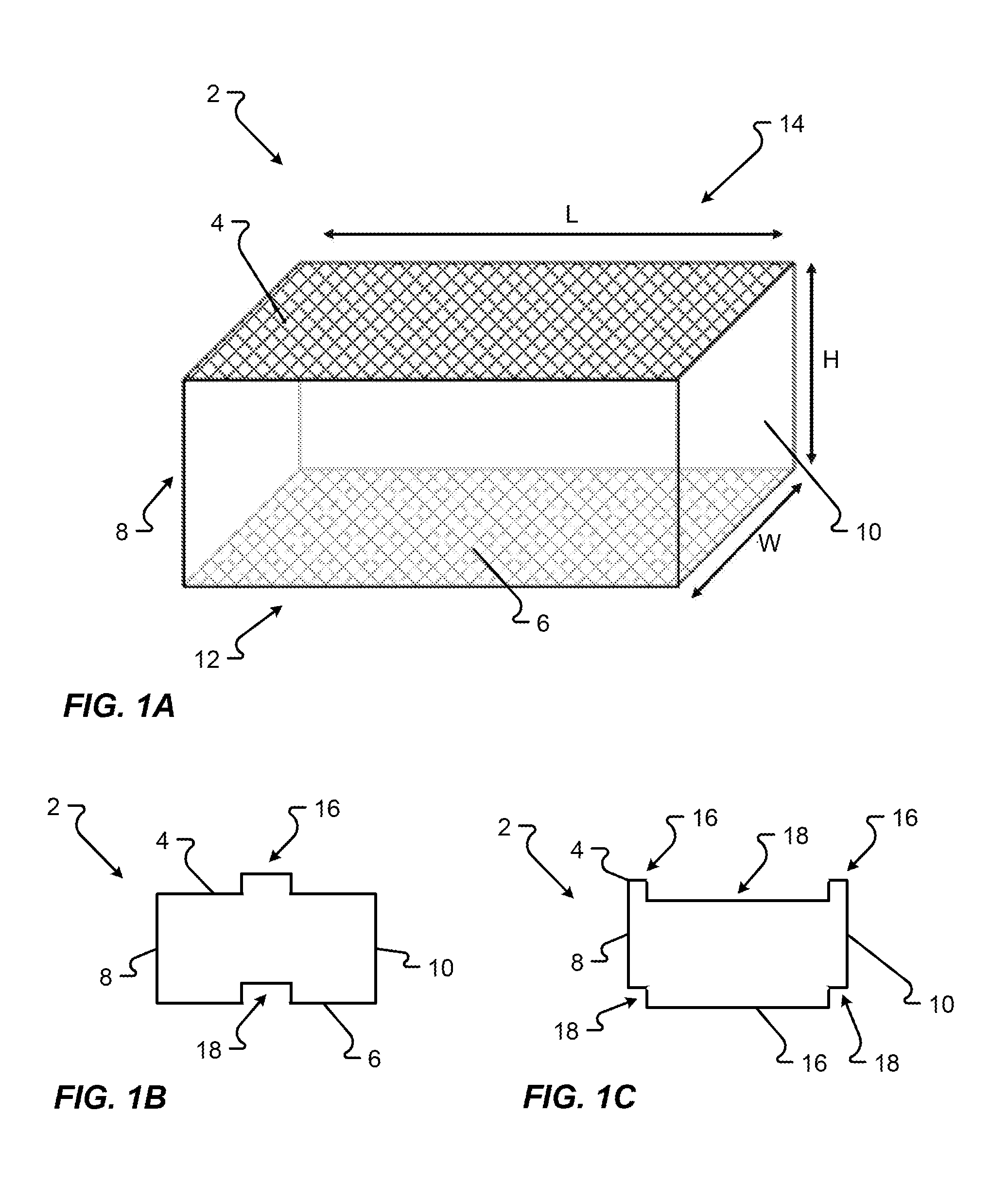

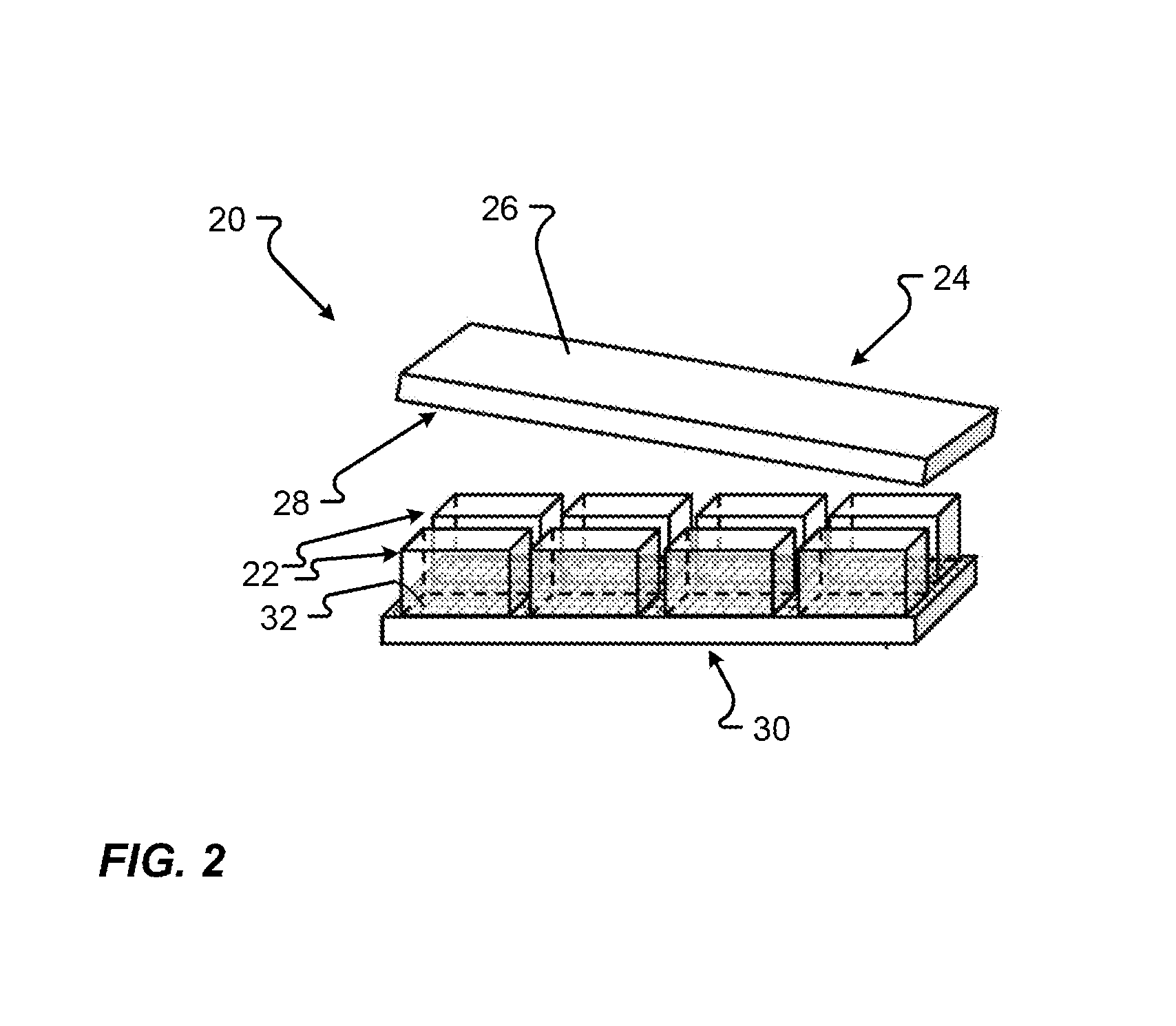

[0037]FIGS. 1-4 show various aspects and embodiments of asphalt brick device 2 of the present invention. Asphalt brick devices 2 may be used for repairing an asphalt site such as a roadway. A user may manufacture asphalt brick devices according to site-specific repair requirements.

[0038]Referring to FIG. 1A, an asphalt brick device 2 is depicted comprising upper surface 4, lower surface 6, left side 8, right side 10, front 12 and rear 14. Asphalt brick device 2 comprises length L, height H and width W. Further, each of upper surface 4 and lower surface 6 comprise a non-uniform surface or textured surface, such as the waffle pattern depicted.

[0039]Referring to FIG. 1B, a front elevation view of an alternate embodiment of an asphalt brick device 2 is depicted. The asphalt brick device 2 comprises upper surface 4, lower surface 6, left side 8, and right side 10. Furthermore, the asphalt brick device comprises a stackable feature: a rectangular protrusion 16 on upper surface 4 and match...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com