Molding Machine for Making Thermoplastic Composites

a molding machine and thermoplastic technology, applied in the direction of presses, manufacturing tools, other domestic objects, etc., can solve the problems of inability to tightly press cloth material and thermoplastic film together, and inability to see the thermoplastic film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

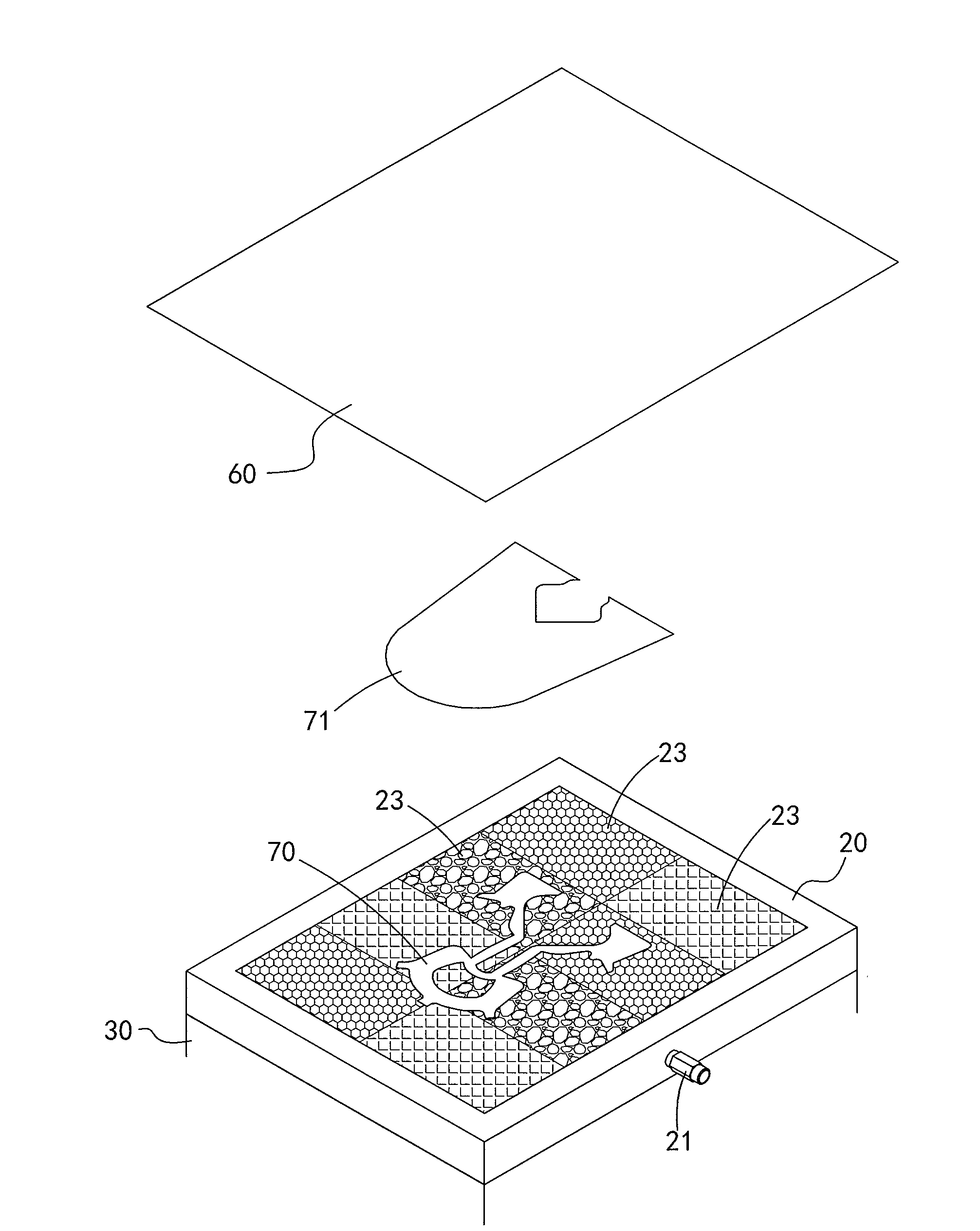

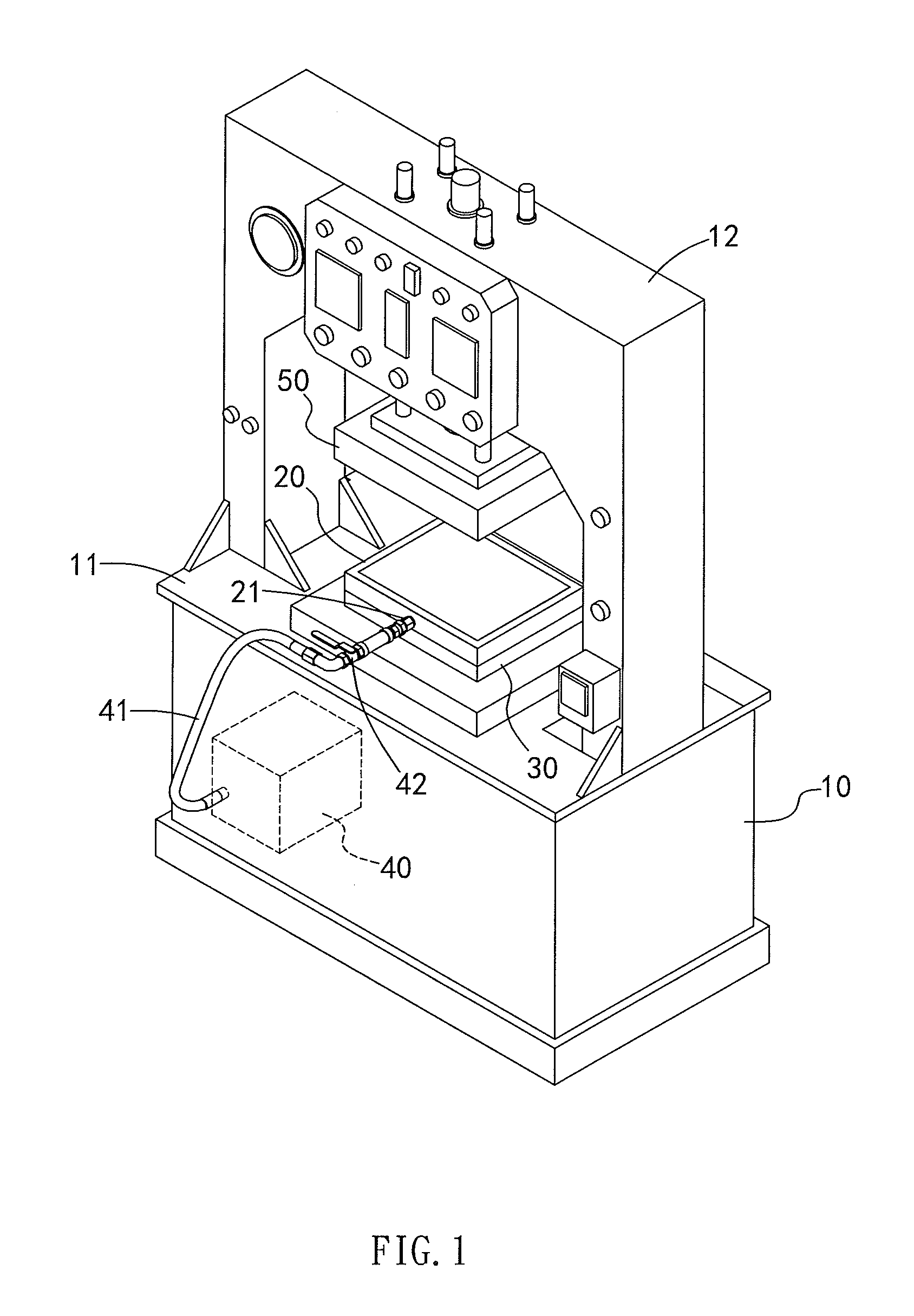

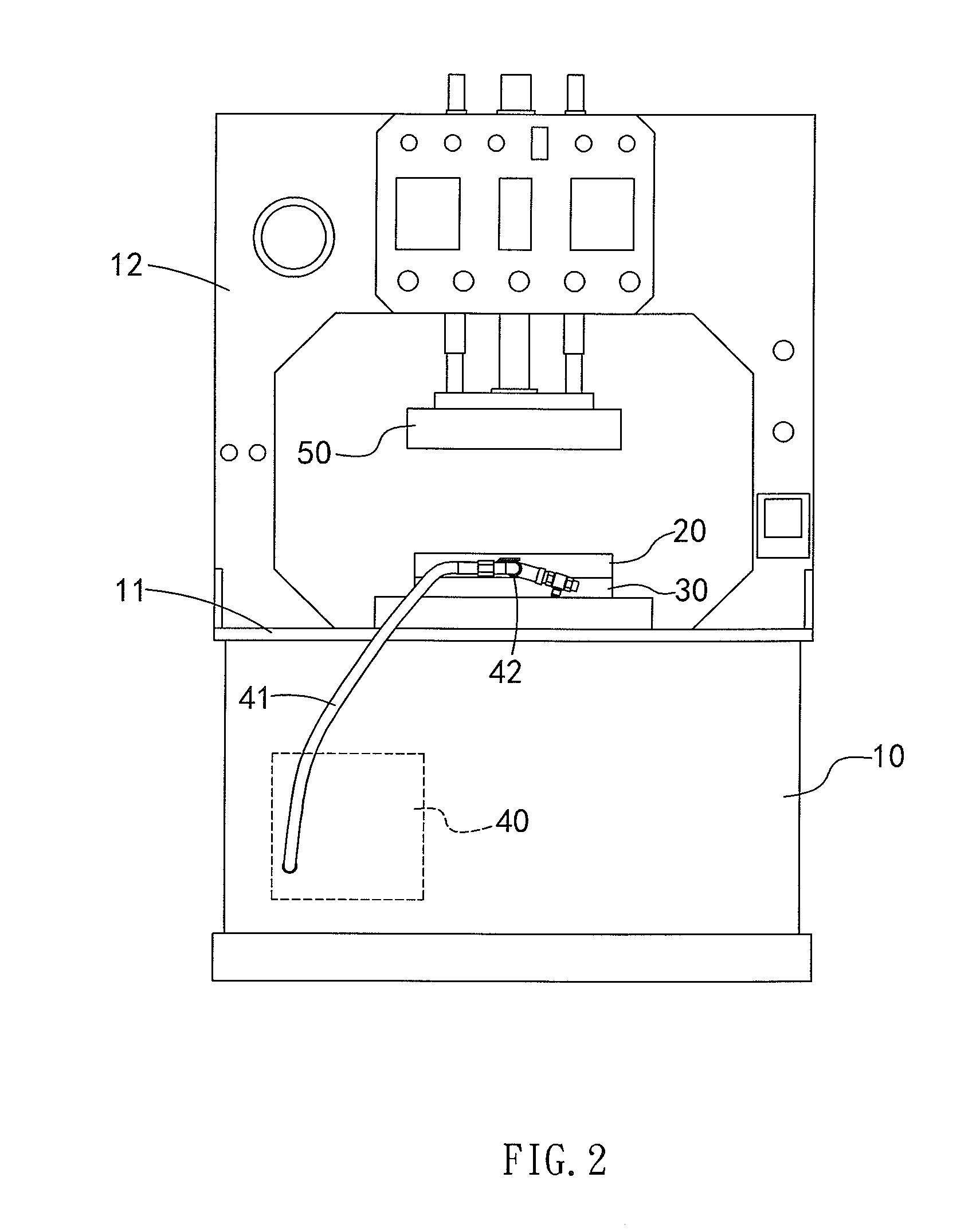

[0021]With reference to FIGS. 1-7, a molding machine for making thermoplastic composites according to a first embodiment of the present invention comprises: a machine frame 10, a platform 20, a heating device 30, a vacuum means 40, a pressing die 50, a gas barrier film 60.

[0022]The machine frame 10 includes a working stage 11 and a C-shaped rack 12 disposed on the working stage 11.

[0023]The platform 20 is mounted on the working stage 11 and includes a connector 21 fixed on one side thereof.

[0024]The heating device 30 is secured on a bottom end of the platform 20 and heats a working material on a top surface of the platform 20.

[0025]The vacuum means 40 is arranged in the machine frame 10 and includes a pipe 41 for coupling with the connector 21 of the platform 20 and a control valve 42 defined at a connecting position of the pipe 41 and the connector 21 so as to control air extraction.

[0026]The pressing die 50 is movably disposed on the C-shaped rack 12 and moves to and presses the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| depths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com