Pre-embedded Piece, Method for Producing the Same, and Reinforcing Steel Structures Including the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

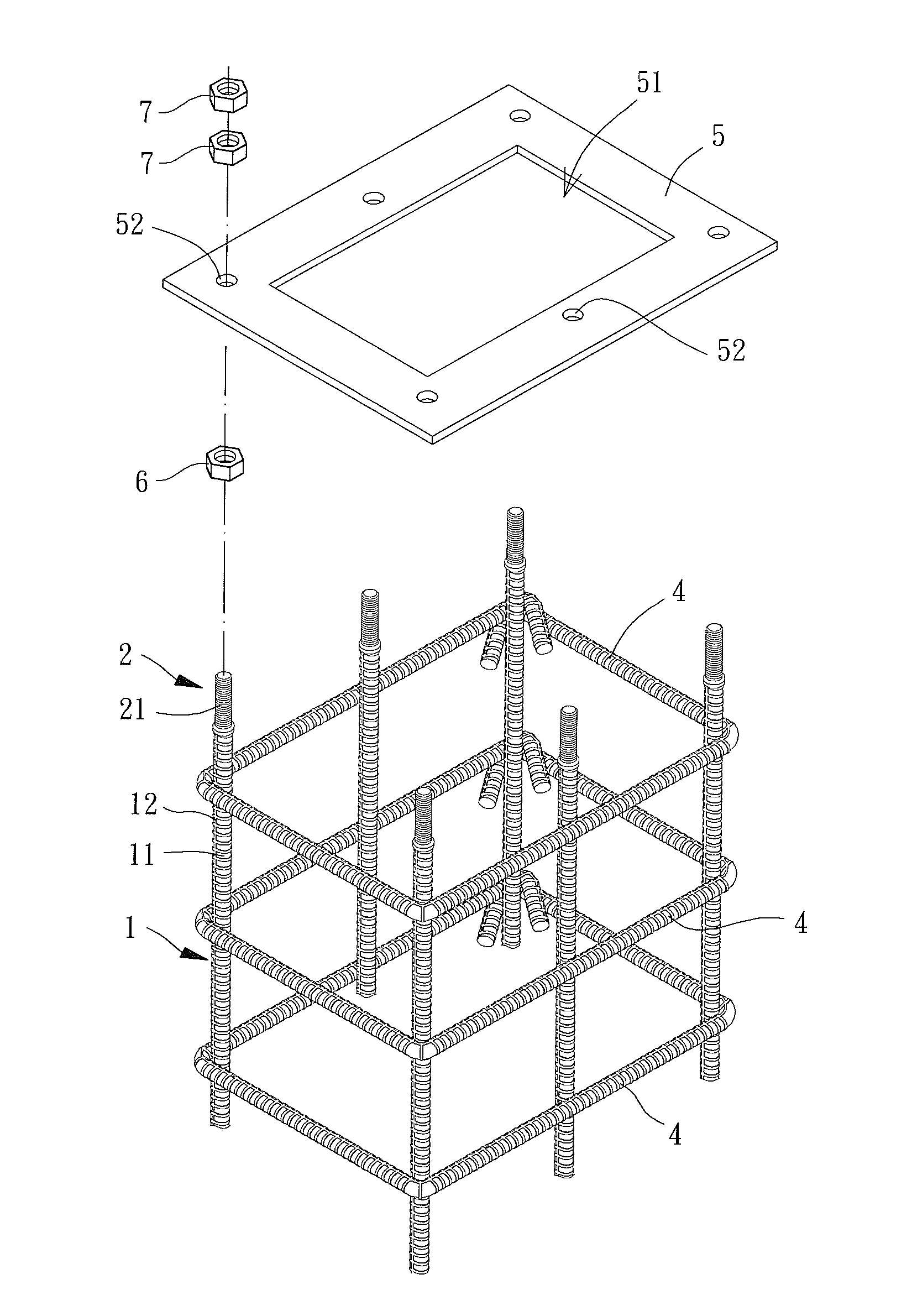

[0042]FIG. 3 shows a pre-embedded piece of an embodiment according to the present invention. The pre-embedded piece includes a reinforcing steel bar 1 and a screw rod 2. The reinforcing steel bar 1 and the screw rod 2 are connected end to end.

[0043]The reinforcing steel bar 1 includes a body 11 and an embossed portion 12. The body 11 is elongated. The embossed portion 12 is formed on an outer periphery of the body 11. In this embodiment, the embossed portion 12 includes a plurality of annular ridges 121 spaced from each other. The annular ridges 121 can be parallel to each other and can be spaced from each other by regular intervals. Preferably, the embossed portion 12 further includes the at least one longitudinal rib 122 extending in a longitudinal direction of the reinforcing steel bar 1 and connecting the annular ridges 121.

[0044]The screw rod 2 includes an outer threaded portion 21. The screw thread of the outer threaded portion 21 can be, but not limited to, triangular, trapez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com