Ribbed foundation for superstructures and method for producing the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

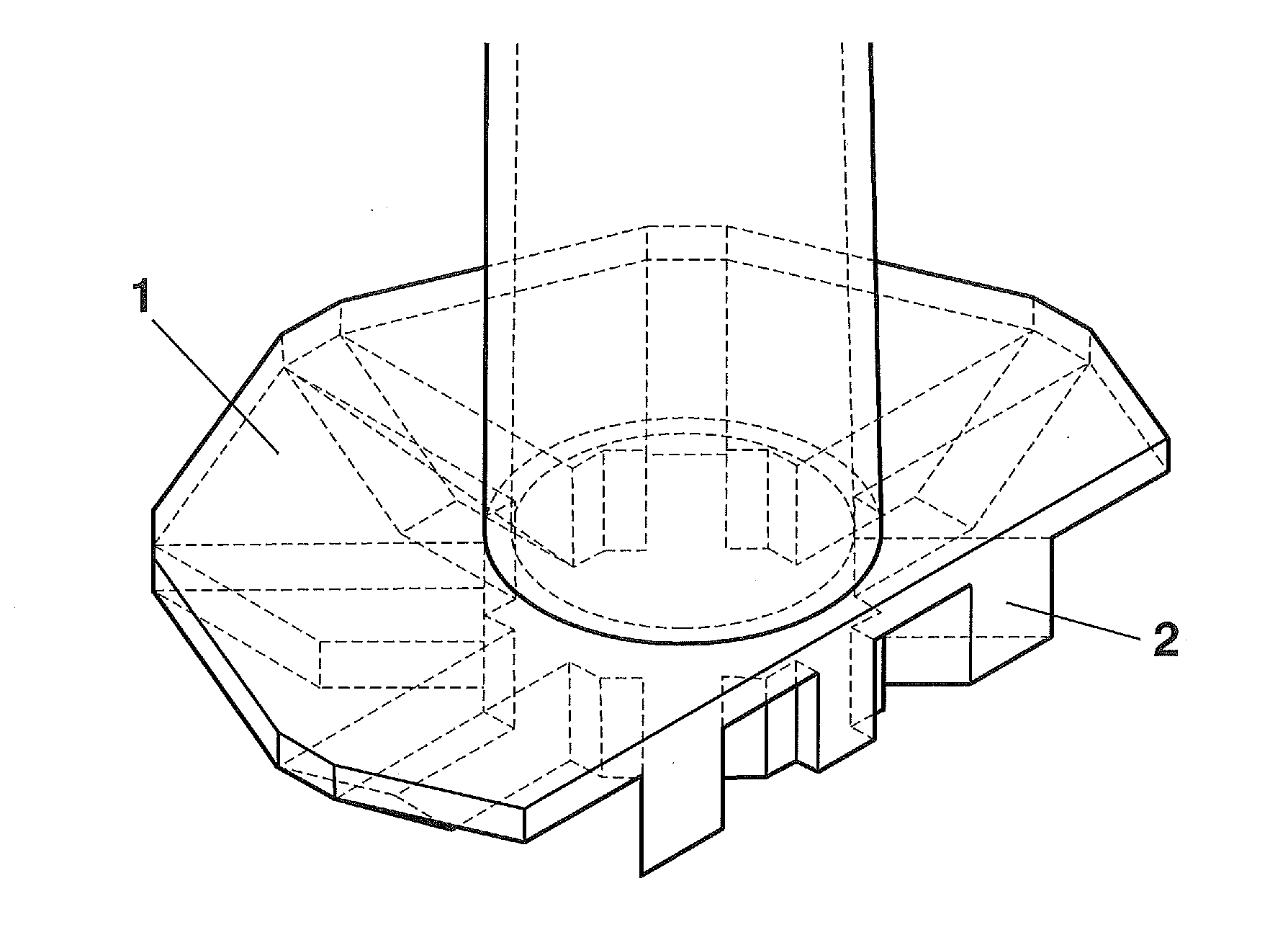

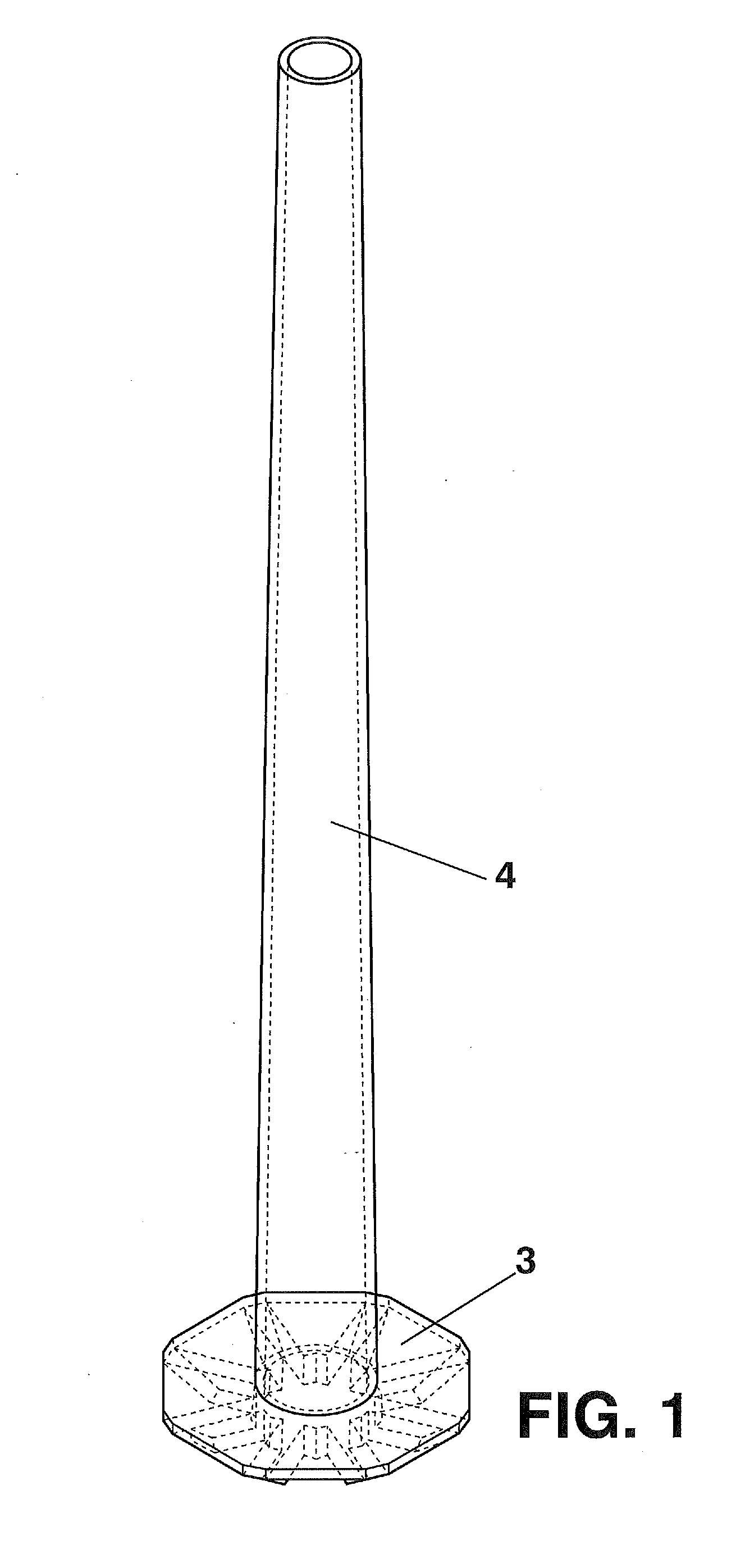

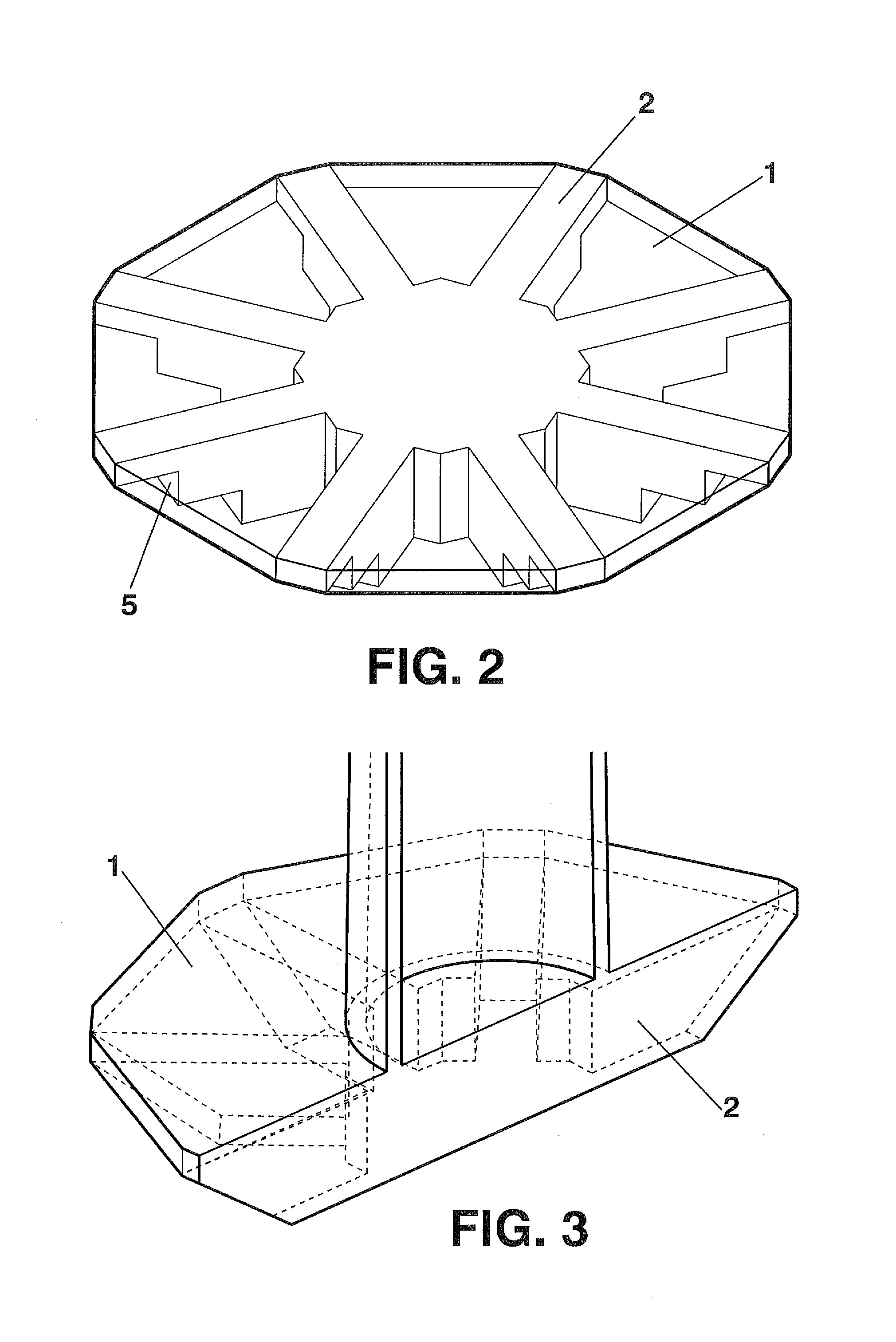

[0010]In an attempt to overcome the mentioned problems in the state of the art, the present invention presents a solution formed by an upper reinforced-concrete slab poured “in situ” having a polygonal or circular footprint and which is made rigid at the bottom by means of reinforced-concrete ribs of a rectangular or trapezial cross-section which are arranged radially stemming from a central core. The concrete for the ribs is poured directly on the previously excavated terrain, whereas the slab rests on the terrain that has not been removed, acting as permanent formwork.

[0011]The solution consisting of an upper slab and ribs making the slab rigid at the bottom refers to the arrangement of both elements with respect to the surface of the ground where the foundation is built, where the slab is arranged first and the stiffening ribs would be arranged below the slab.

[0012]The advantages of this foundation are[0013]The volume of concrete used is much less than in the conventional solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com