Axial turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

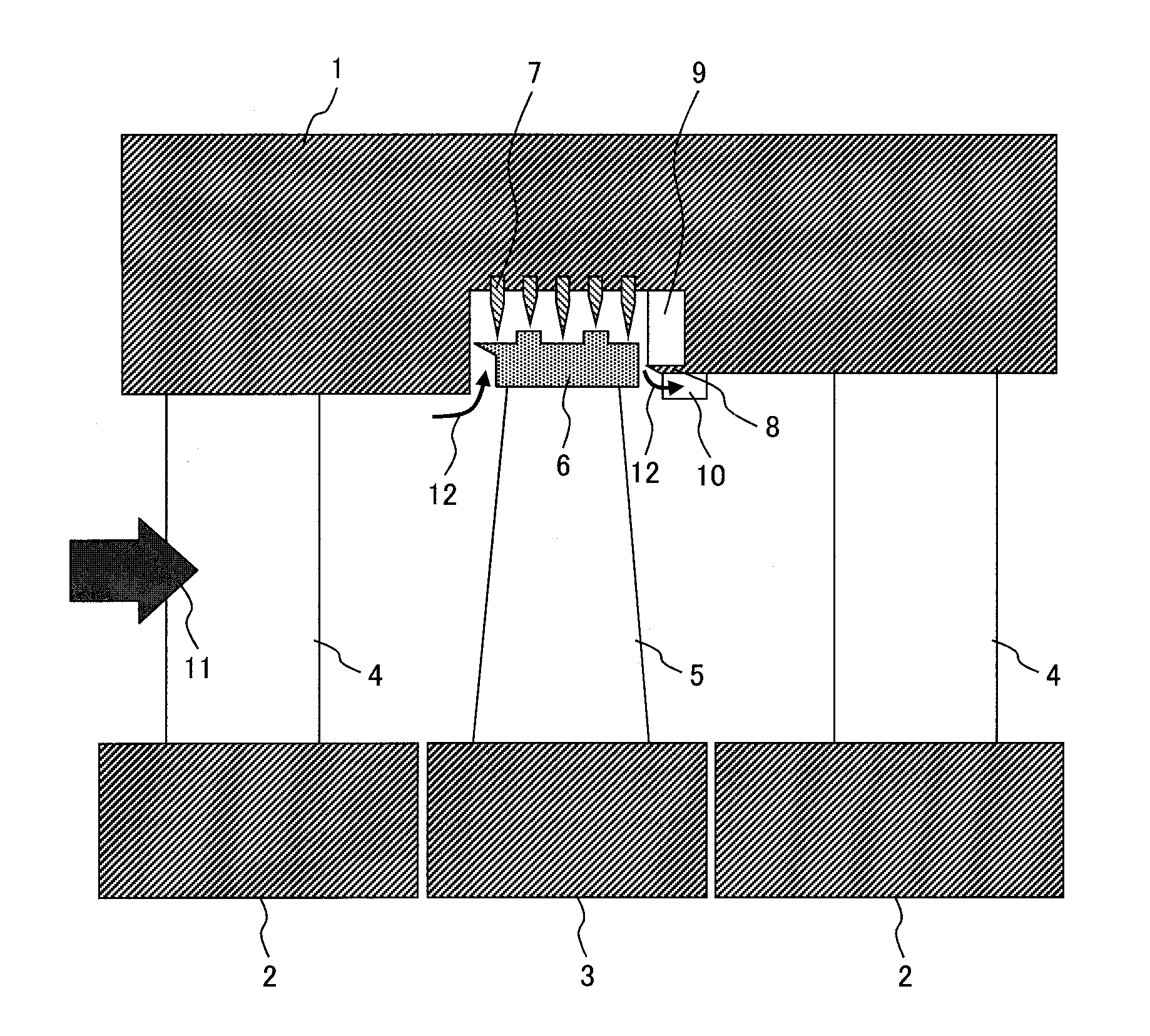

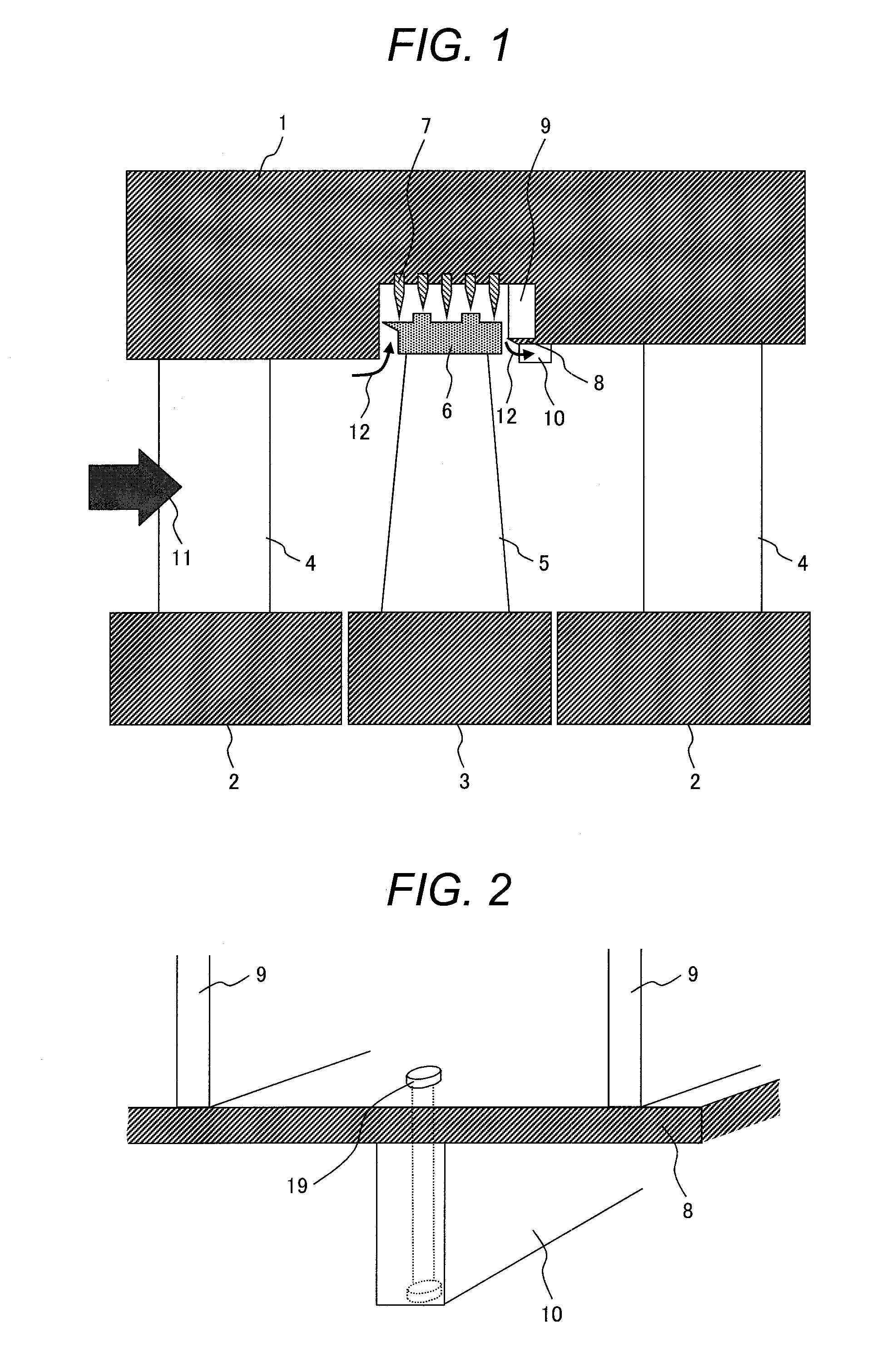

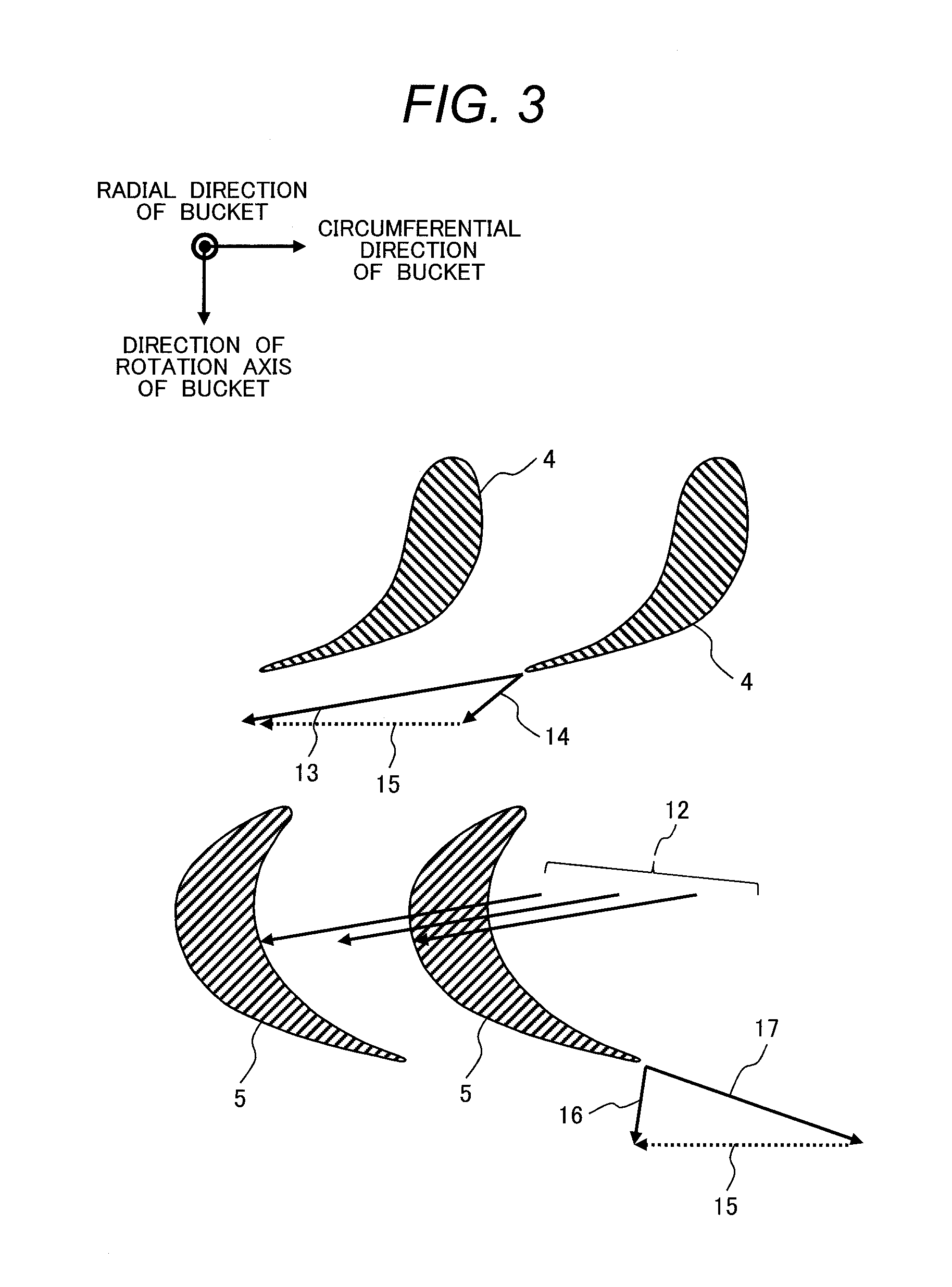

[0024]FIGS. 1 and 2 each show a stage structure of a steam turbine according to a first embodiment of the invention. A turbine-stage of the steam turbine according to the present embodiment is provided with a rotatably supported rotor 3, a bucket 5 fixed to the rotor 3, a shroud 6 provided at the tip of the bucket 5, a diaphragm outer ring 1 opposed to the shroud 6 with a gap provided therebetween, a radial seal fin 7 provided in such a way as to protrude from the diaphragm outer ring 1 in the radial direction of the rotor 3 in a gap between the shroud 6 and the diaphragm outer ring 1, an axial seal fin 8 provided in such away as to protrude from the diaphragm outer ring 1 in the direction of a rotation axis of the rotor 3 in a gap between the shroud 6 and the diaphragm outer ring 1, a plurality of ribs 9 provided in such a way as to be sandwiched between the diaphragm outer ring 1 and the axial seal fin 8 and to be extended from the diaphragm outer ring 1 towards the shroud 6 in th...

second embodiment

[0042]FIGS. 10, and 11 each show a stage structure of a steam turbine according to a second embodiment of the invention. Further, FIG. 12 is a plan view of a guide plate 10 shown in FIG. 11. A turbine stage of the steam turbine according to the present embodiment is provided with a rotatably supported rotor 3, a bucket 5 fixed to the rotor 3, a shroud 6 provided at the tip of the bucket 5, a diaphragm outer ring 1 opposed to the shroud 6 with a gap provided therebetween, a radial seal fin 7 provided in such a way as to protrude from the diaphragm outer ring 1 in the radial direction of the rotor 3 in a gap between the shroud 6 and the diaphragm outer ring 1, an axial seal fin 8 provided in such a way as to protrude from the diaphragm outer ring 1 in the direction of the rotation axis of the rotor 3 in the gap between the shroud 6 and the diaphragm outer ring 1, a plurality of ribs 9 provided in such a way as to be sandwiched between the diaphragm outer ring 1 and the axial seal fin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com