Grill pan and grill cookware using the same

a technology of grilling pan and cookware, which is applied in the direction of frying pans, roasters/grills, kitchen equipment, etc., can solve the problems of releasing considerable fat, meat becomes too greasy and unhealthy, and the effect of less greasy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

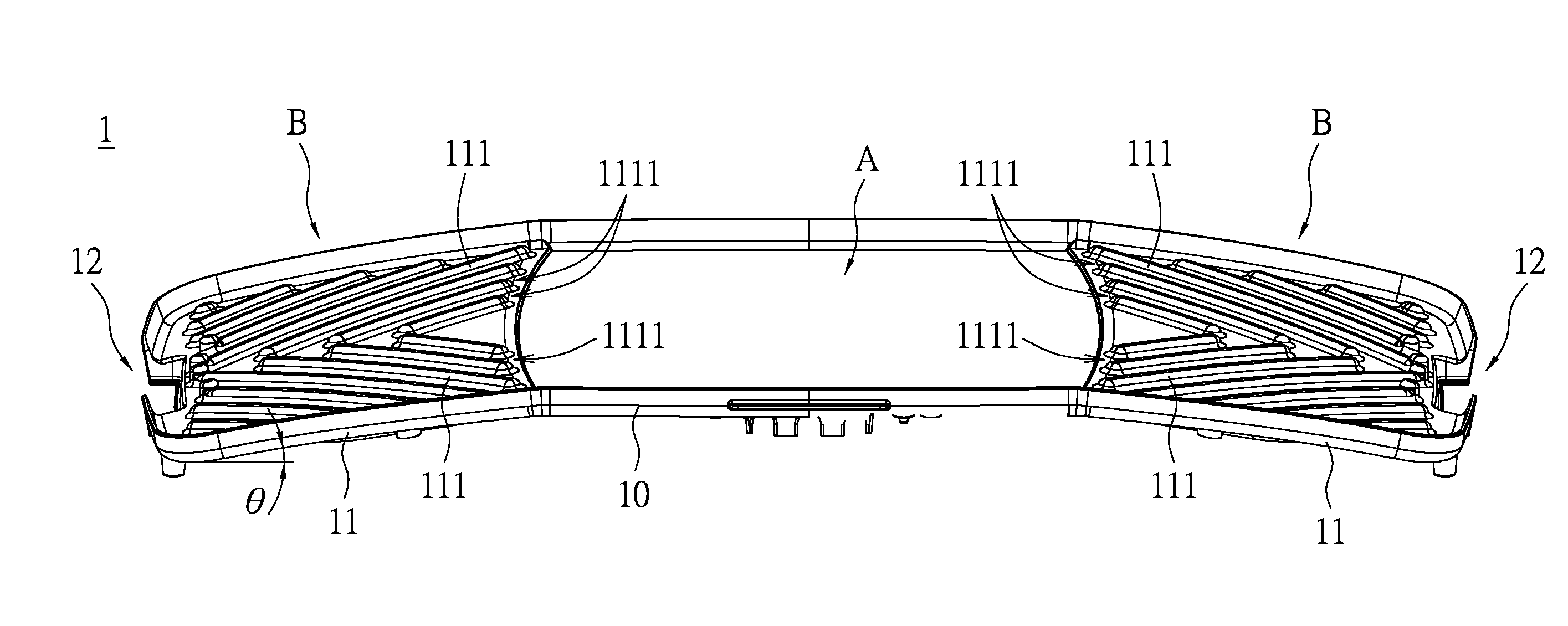

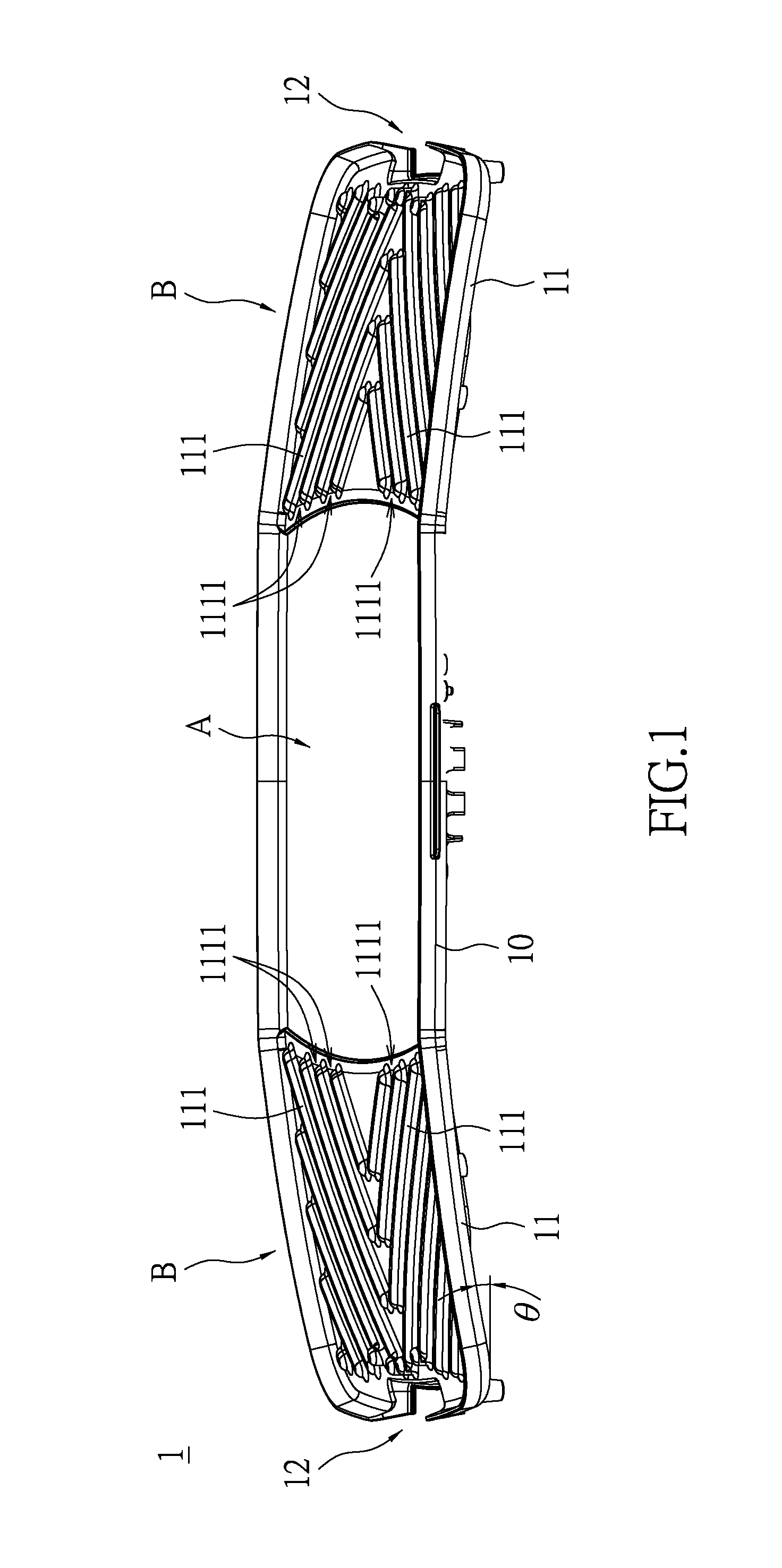

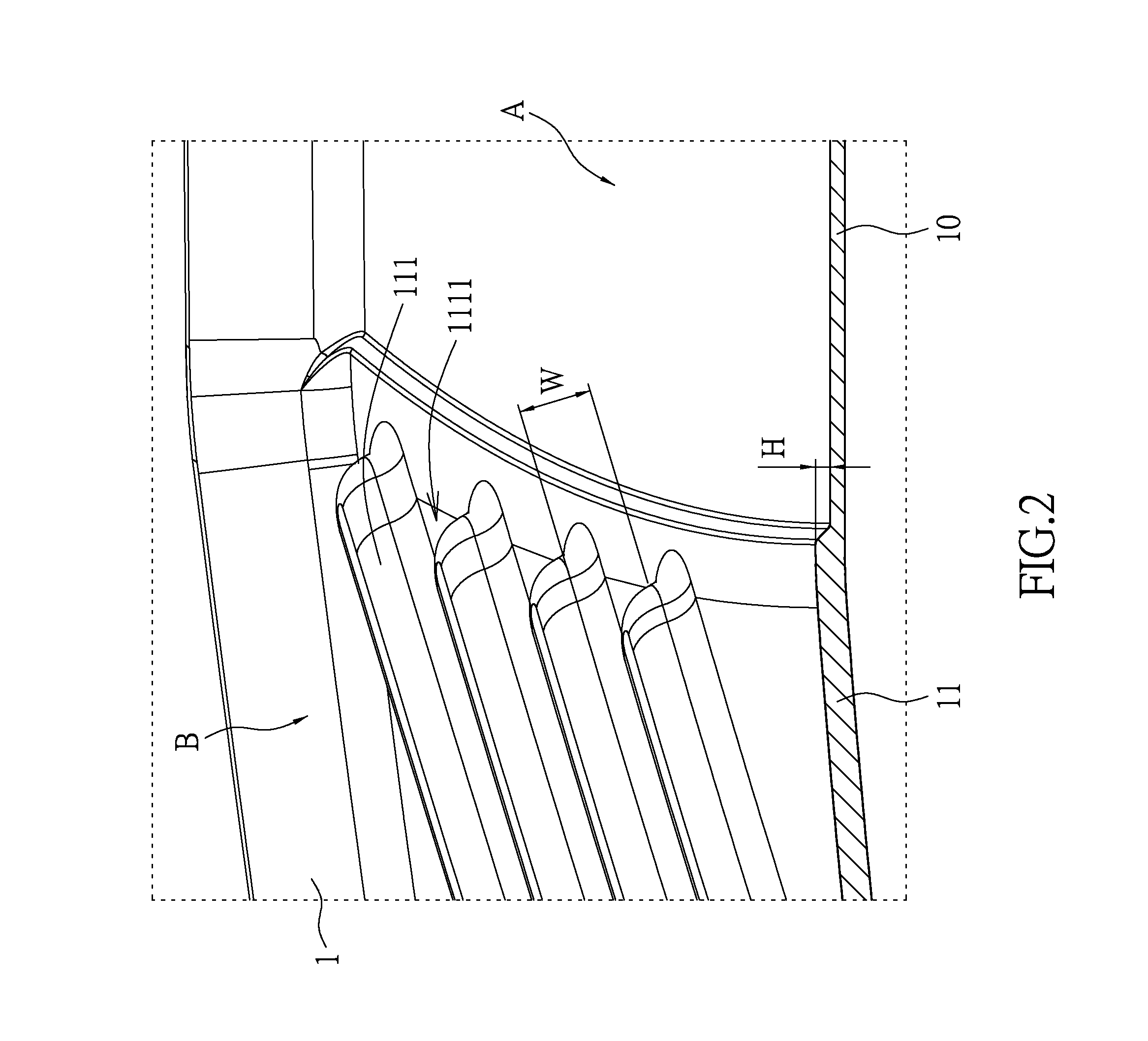

[0023]Please refer to FIGS. 1 and 2 showing a first embodiment of the instant disclosure. A grill pan 1 includes a flat portion 10 and two slanting portions 11 as shown in the figures. Each of the slanting portions 11 is connected to the opposite sides of the flat portion 10 respectively, and a height difference H is created between where the flat portion 10 and each of the slanting portions 11 meet. Therefore the flat portion 10 is slightly below the slanting portions 11. The height difference H divides a cooking area for low-fat food A and a cooking area for high-fat food B. The height difference H ranges between 1-10 mm, preferably 1.5 mm. The area of the flat portion 10 and the slanting portions 11 falls in 100-900 cm2.

[0024]Each of the slanting portions 11 is a tilted structure and slopes down from where it is connected to the flat portion 10. The slanting portions 11 are formed with a spout 12 to collect fat generated during cooking food at the cooking area for high-fat food. ...

second embodiment

[0032]Please refer to FIG. 6, showing a top view of the grill pan in accordance with a second embodiment of the instant disclosure. The difference between the first and second embodiment arises from a guiding channel 112. The guiding channels 112 are respectively disposed on the flat portion opposite to the spouts 12. The guiding channels 112 allow fluid communication between the flat portion 10 and the slanting portions 11. The fat on the flat portion 10 produced during cooking flows through the guiding channels 112 to the slanting portions 11 and down to the spout 12. Specifically, when cooking low-fat food on the flat portion 10, fat is also produced. The fat can go through the guiding channels 112 to the spout 12, such that the flat portion 10 is free from excessive fat. Of course, fat removing equipments (for example, scraper) may be used to collect the fat on the flat portion 10 and sweep to the guiding channels 112 and then down to the spout 12. Moreover, the guiding channels...

third embodiment

[0033]Please refer to FIGS. 7 and 8, showing schematic diagrams of a grill cookware of the instant disclosure. The grill cookware 2 includes a grill pan 1, a base 21, two fat tanks 22, at least one heating tube 23 and a control unit 24. The grill pan 1 used in the first embodiment is identical to the grill pan 1 in the second embodiment and is formed in an identical manner. Therefore, the specifics of same are not repeated herein. The grill pan 1 is disposed on the base 21. The base 21 has two fat tank holders 211 close to the spout 12 of the grill pan 1 for accommodating the fat tanks 22. The fat flowing out from the spout 12 of the grill pan 1 is collected in the fat tanks 22. The base 21 may also have two handles 212 at both ends to facilitate the grill cookware 2 handling.

[0034]In addition, the fat tanks 22 may be mechanically attached to the fat tank holders 211 of the base or through non-mechanically means. For example, each fat tank 22 may be retractably disposed on the fat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com