Powdered chocolate

A technology of chocolate and powder, which is applied in the direction of fat oil/fat/wax solidification, cocoa, edible oil/fat, etc. It can solve the problems of greasy, difficult to eat, and not tasty, and achieve the effect of reducing manufacturing costs and making it easy to eat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] (a) Preparation process I of oil and fat composition

[0071] The oil and fat composition prepared in the step (a) contains the above-mentioned XXX type triglycerides (one type or more) and X2Y type triglycerides (one type or more than one type) in the above mass %. Specifically, for example, XXX type triglycerides (one type or more) having fatty acid residue X with carbon number x at positions 1 to 3 and those having carbon number y at positions 1 to 3 are obtained respectively The YYY type triglycerides (1 or more) of fatty acid residue Y are mixed with a mass ratio of XXX type triglycerides / YYY type triglycerides of 90 / 10 to 99 / 1 to obtain a reaction substrate ( Here, the aforementioned carbon number x is an integer selected from 8-20, and the aforementioned carbon number y is an integer selected from x+2~x+12, and y≤22). After heating the aforementioned reaction substrate, It is obtained by performing a step of transesterification reaction in the presence of.

[0072] ...

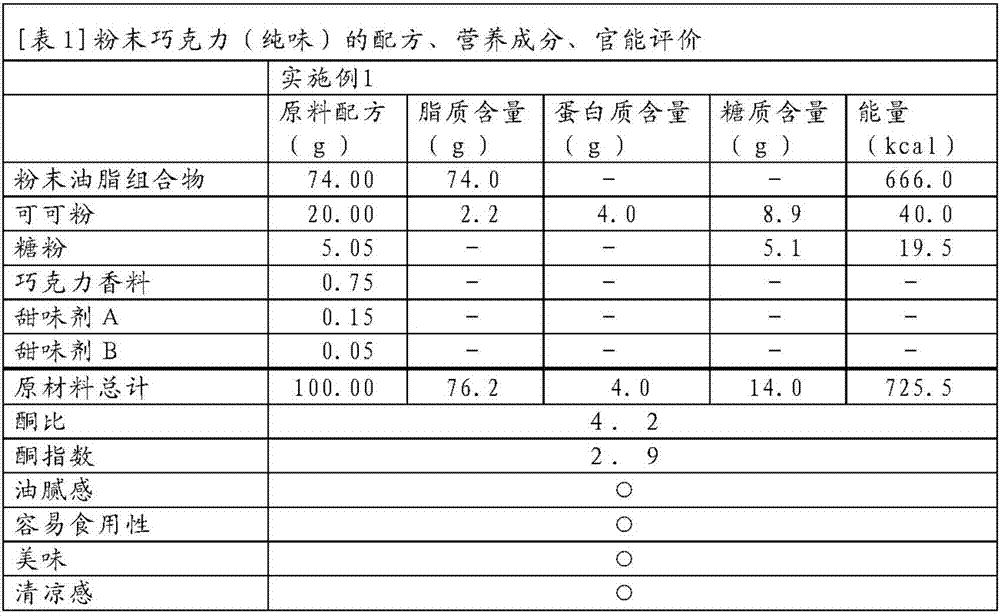

Embodiment 1

[0152]

[0153] According to the formula of Table 1 below, the powdered chocolate (pure flavor) of Example 1 was produced. More specifically, to the powdered oil and fat composition put in the container, cocoa powder, powdered sugar, chocolate flavor, sweeteners A and B are added, and they are mixed with a spatula to prepare powdered chocolate (pure flavor). It should be noted that the cocoa powder described below contains 11% by mass of lipids, 20% by mass of proteins, and 44.5% by mass of carbohydrates.

[0154] [Table 1]

[0155]

[0156]

[0157] The powdered chocolate (pure taste) of Example 1 manufactured as described above was subjected to sensory evaluation according to the following evaluation method.

[0158]

[0159] (1) Evaluation method of greasy feeling

[0160] Based on the following criteria, 5 skilled panel members will conduct comprehensive evaluations.

[0161] ○: No greasy

[0162] △: Slightly greasy

[0163] ×: greasy

[0164] (2) Evaluation method of ease of eating ...

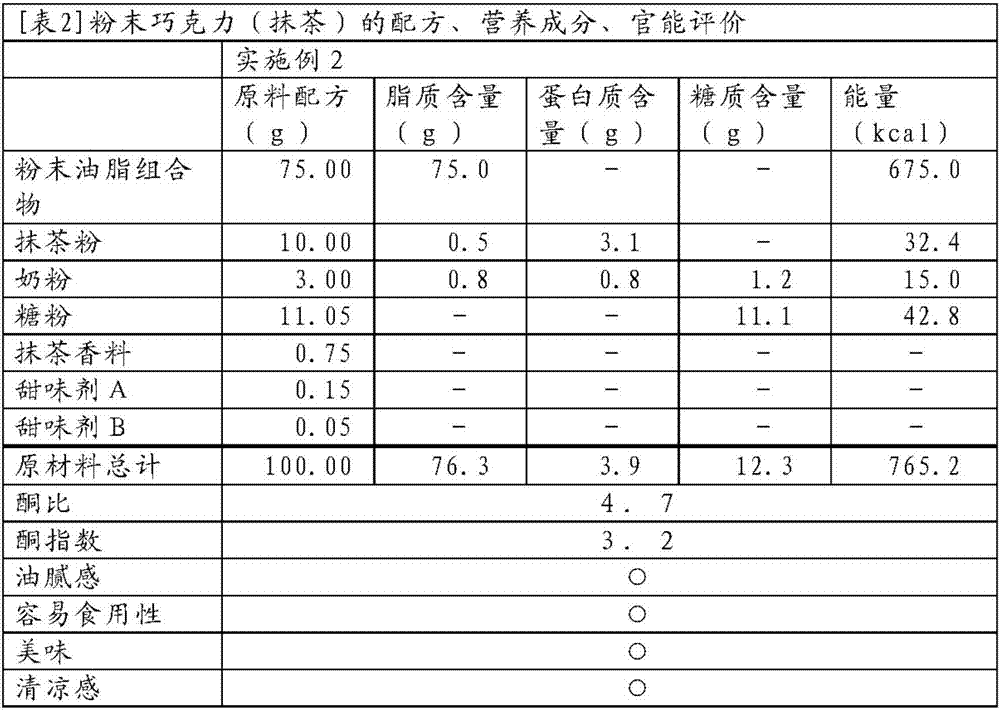

Embodiment 2

[0181]

[0182] According to the formula of Table 2 below, powdered chocolate (Matcha) of Example 2 was produced. More specifically, to the powdered oil and fat composition put into the container, matcha powder, milk powder, powdered sugar, matcha flavor, sweeteners A and B are added and mixed with a spatula to prepare powdered chocolate (matcha) . It should be noted that the matcha powder contains 5.3% by mass of lipid and 30.6% by mass of protein. Furthermore, the milk powder contains 26.2% by mass of lipids, 25.5% by mass of proteins, and 39.3% by mass of carbohydrates. In addition, the values of lipid content, protein content, and carbohydrate content are obtained by rounding the second decimal place.

[0183] [Table 2]

[0184]

[0185]

[0186] The powdered chocolate (Matcha) of Example 2 manufactured as described above was subjected to sensory evaluation in accordance with the evaluation method of Example 1 described above.

[0187] The results in Table 2 show that for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com