Method and apparatus for producing unconventional oil at shallow depths

a technology of unconventional oil and shallow depths, applied in the direction of survey, directional drilling, borehole/well accessories, etc., can solve the problems of small percentage of the unconventional oil and gas in place, high cost of unconventional wells,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

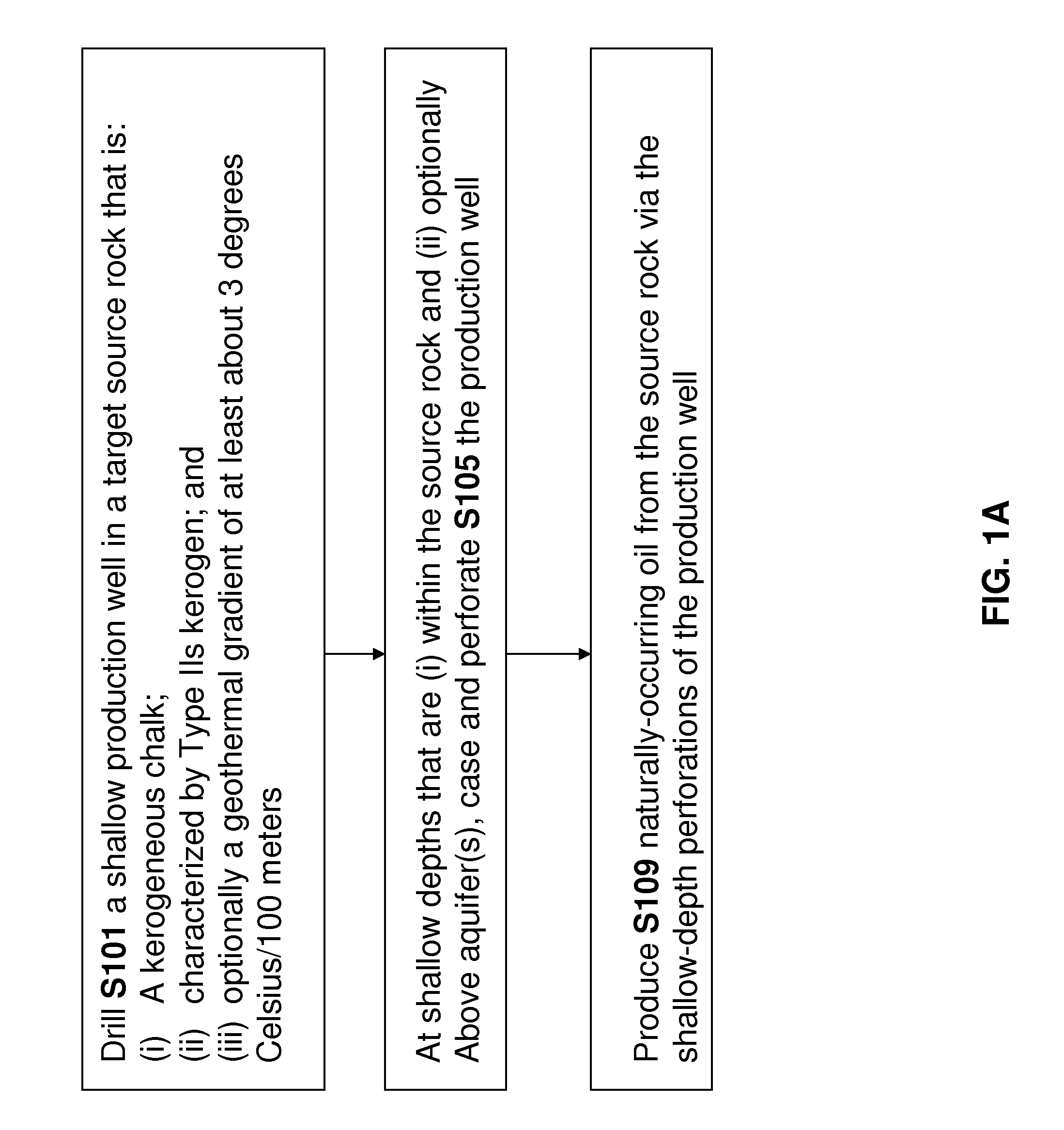

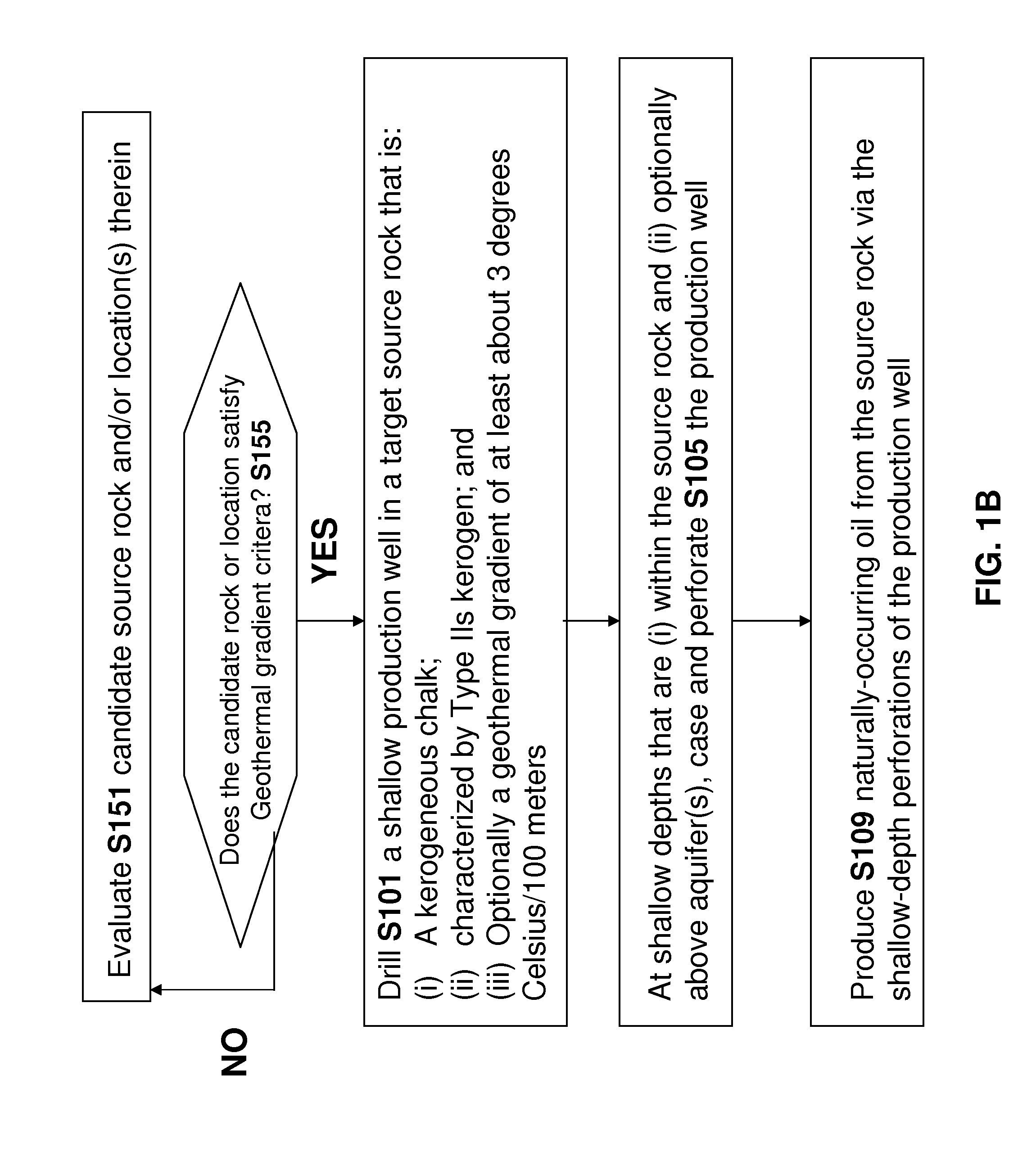

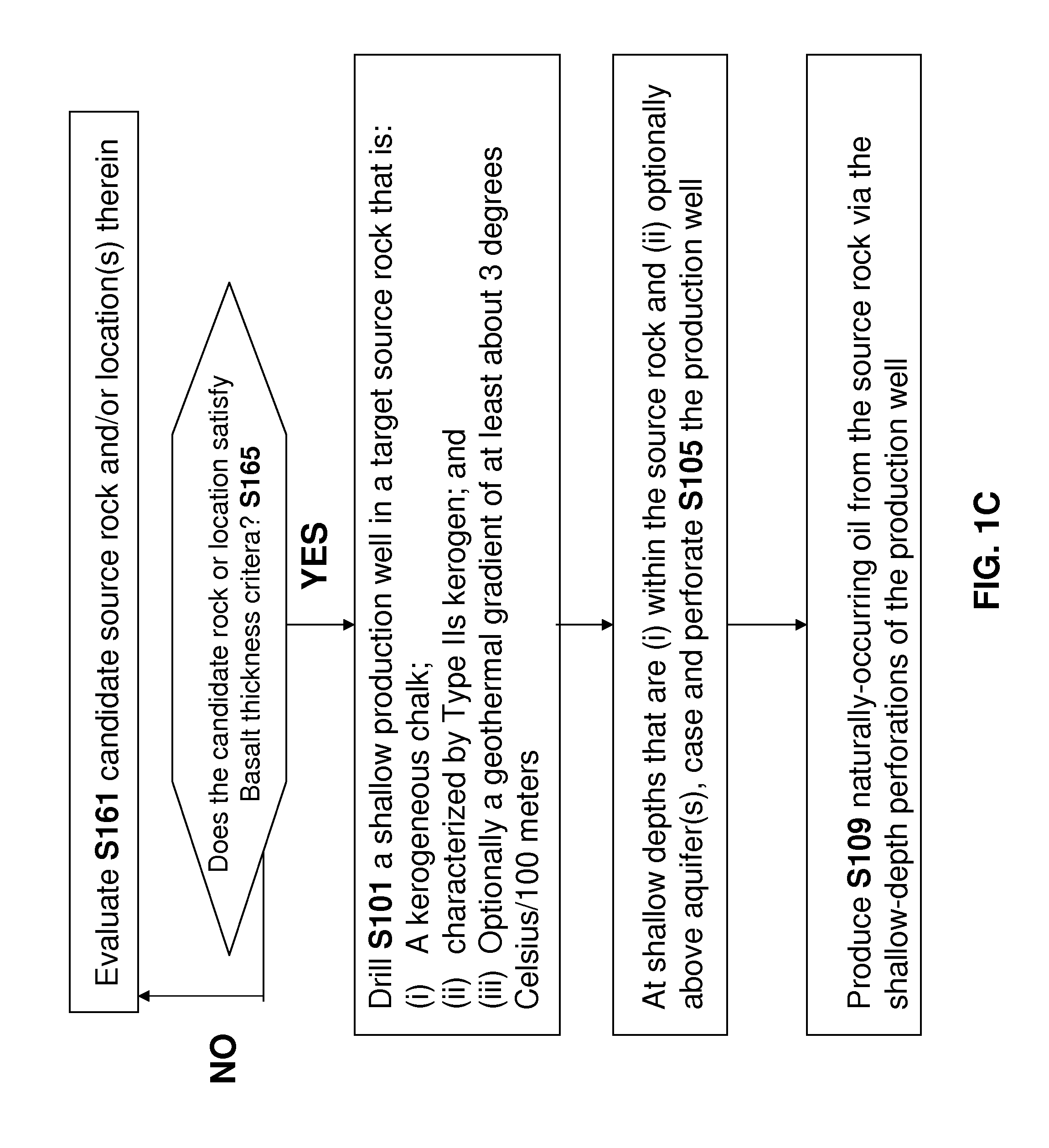

[0003]Instead of relying on artificial heat to pyrolyze kerogen of a kerogenous chalk into pyrolysis fluids (i.e. as is common in in-situ conversion processes (ICP)), it is possible to drill for oil in a kerogenous chalk where natural events (e.g. historical volcanic or other geothermal activities) supplied sufficient thermal energy to convert kerogen of the source rock into naturally-occurring oil. In particular, the present invention relates to techniques where production wells (e.g. shallow wells) are drilled into a kerogenous chalk that is characterized by Type IIs kerogen, a porosity of at least 30% and at a location where the geothermal gradient is at least 3 degrees Celsius per 100 meters.

[0004]In contrast with the aforementioned ICP techniques where (i) oil is only created within the subsurface after an extended period of time (e.g. at least months or years) and where (ii) there is a need to invest significant thermal energy in order to pyrolyze kerogen, according to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com