Gasket device for the bearing of a turbomachine, comprising two elastic seals

a gasket device and turbomachine technology, applied in the field of turbomachines, can solve the problems of difficult to achieve tightness in use and general inability of turbomachine bearings to meet these needs, and achieve the effect of improving tightness of the device in us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

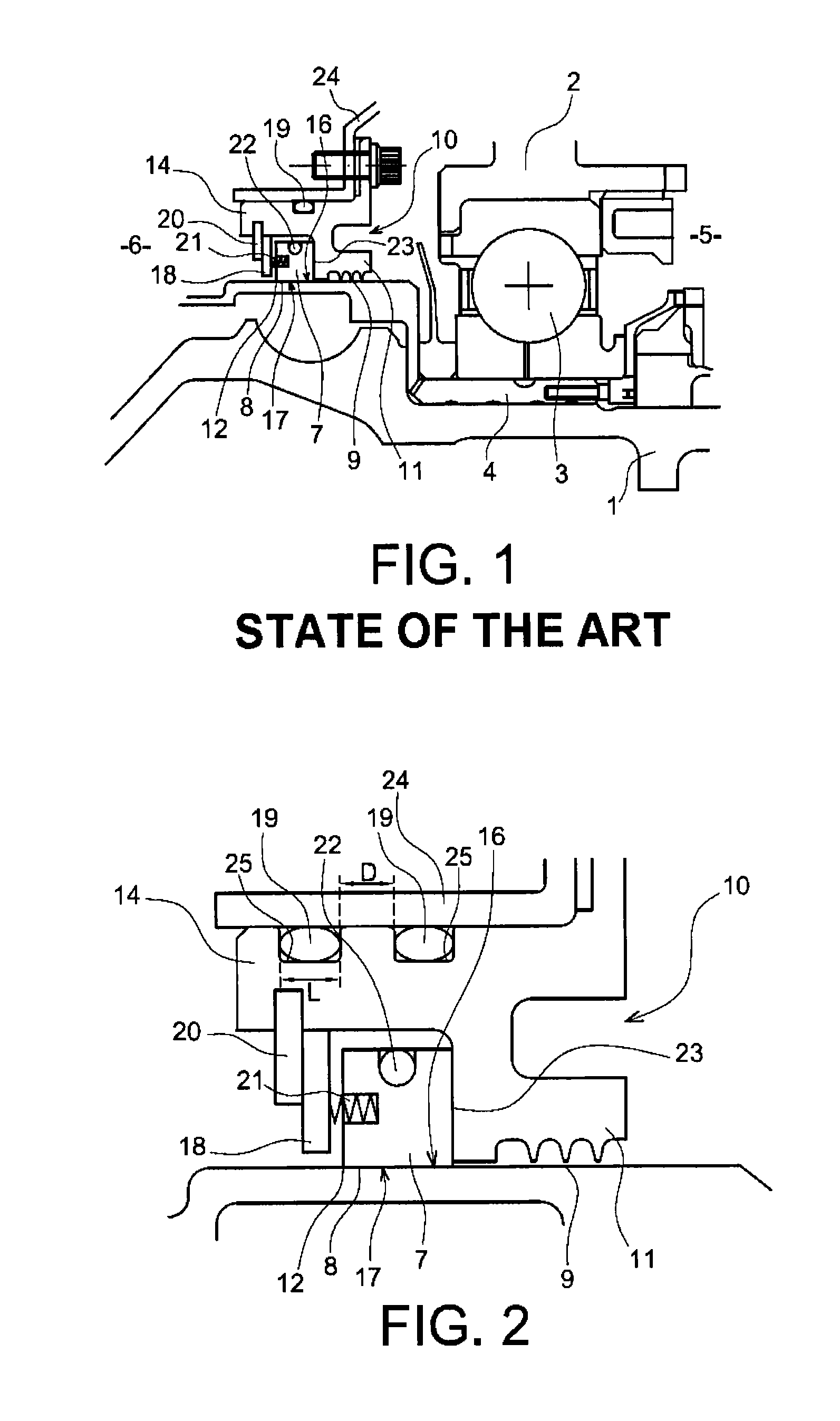

[0038]An exemplary embodiment of the invention relating to a gasket device for a turbomachine bearing will be described hereinafter in reference to FIG. 2.

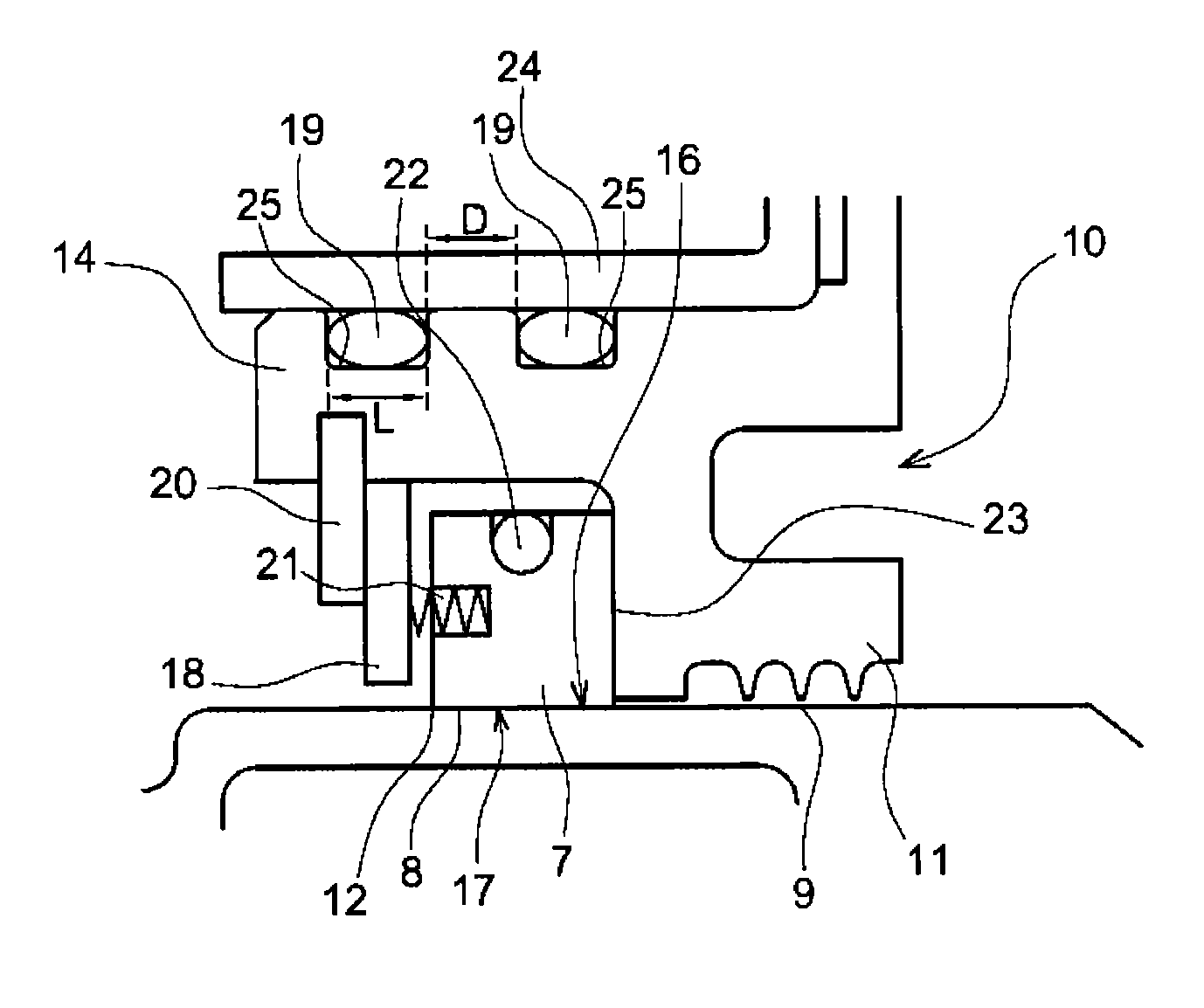

[0039]The turbomachine bearing is similar to that described in reference to FIG. 1.

[0040]Thus, the bearing includes a balling bearing 3 mounted between a sleeve 4 integral with a shaft 1 and a case 2, the sleeve 4 having a rotating surface 8 and the case 2 including a case element 24 acting as a cover for the gasket device 10. The gasket device 10 is able to separate an oil enclosure 5 from the balling bearing 3 and an air enclosure 6 from the turbomachine.

[0041]On the other hand, the sealing device 10 represented in FIG. 2 differs from that represented in FIG. 1 in that it includes a supporting jacket 14 including two housings 25 each accommodating an elastic seal 19, in accordance with the invention.

[0042]More precisely, the gasket device 10 includes a segmented gasket 7, consisting of a static sealing ring of carbon segments he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dimensions | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com