Heat exchanger utilizing tubular structures having internal flow altering members and external chamber assemblies

a technology of heat exchangers and tubular structures, which is applied in the direction of tubular elements, lighting and heating apparatus, cleaning heat exchange devices, etc., can solve the problems of reducing pressure resistance, reducing the efficiency of pipe heat exchangers, and prone to damage of thinner tubes, so as to reduce overall cost, reduce the overall cost, and reduce the overall length of enhanced tubes for heat exchange applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

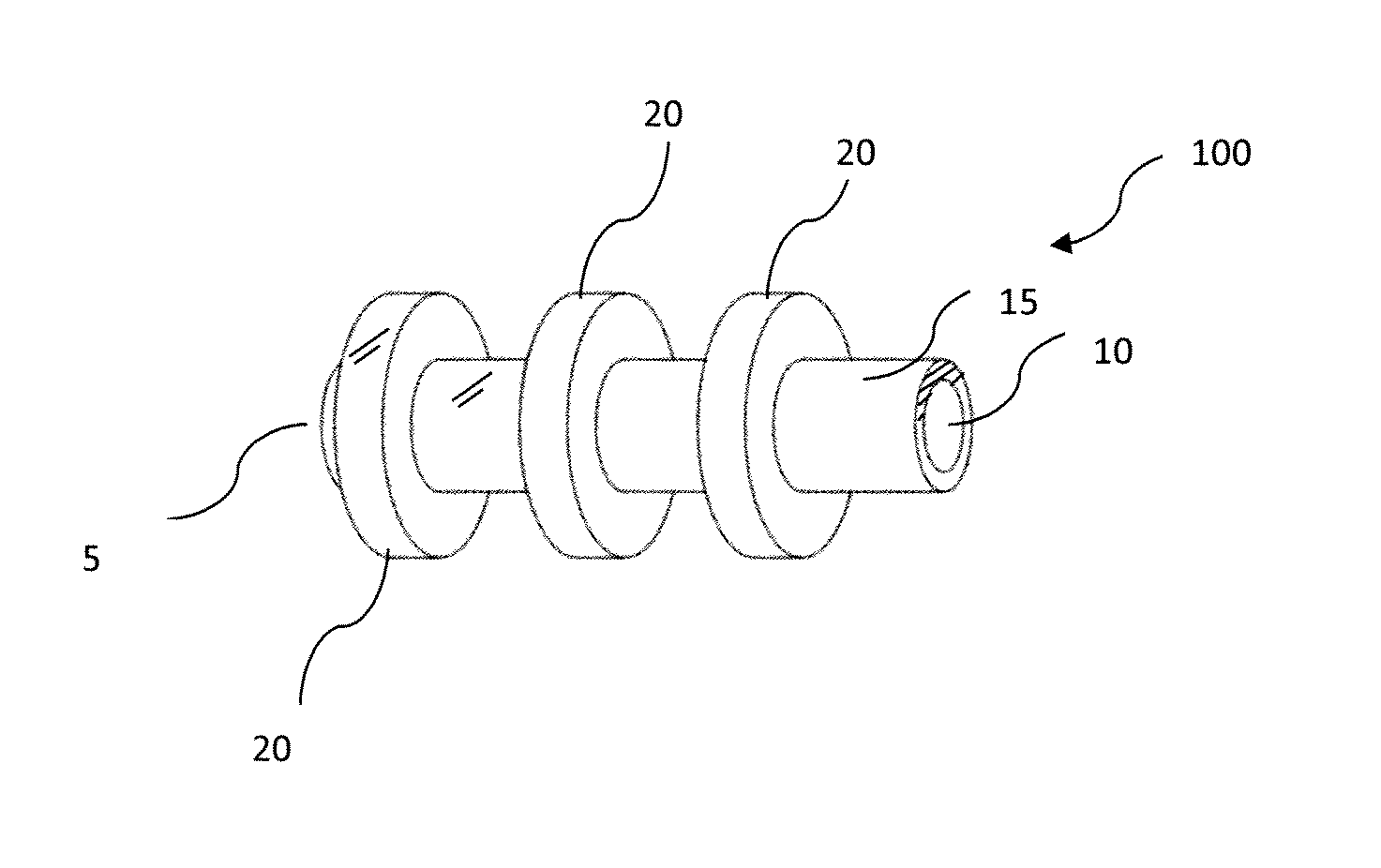

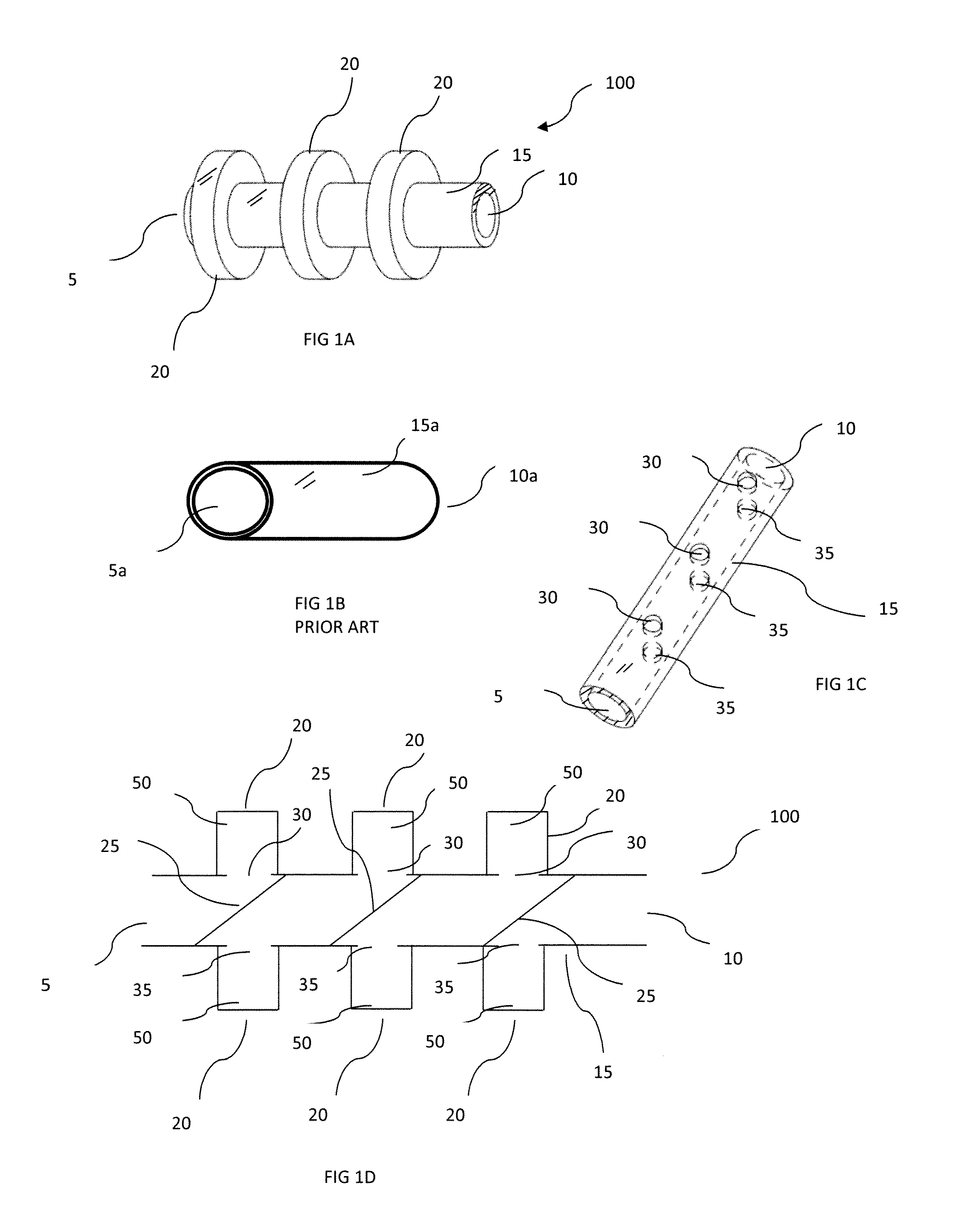

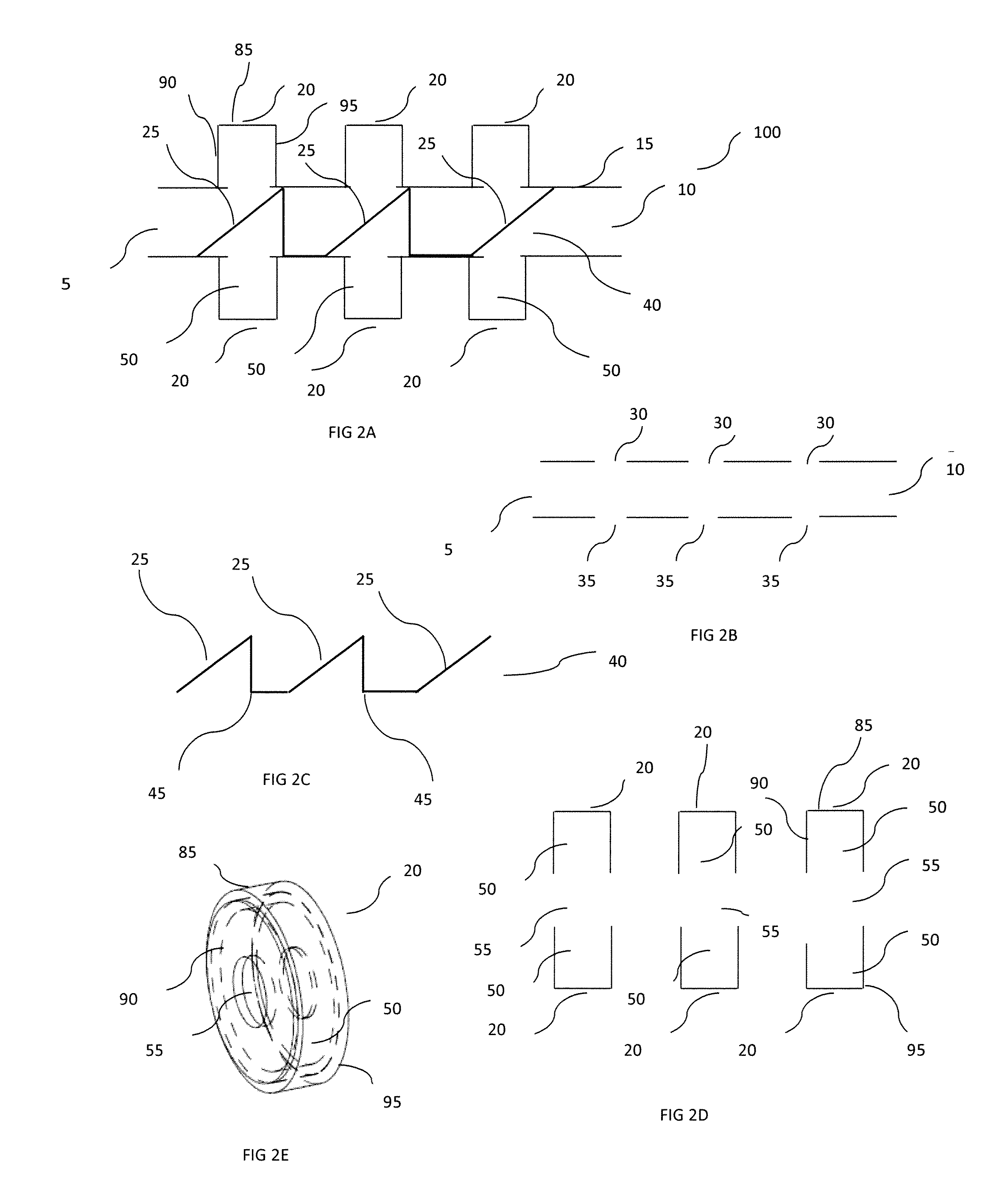

[0071]Referring to the drawings and in particular FIG. 1A, an embodiment of a cylindrical tubular member 100 is shown. The cylindrical tubular member 100 has an inlet 5 to introduce a heat exchange medium into the cylindrical tubular member 100, and an outlet 10 to allow the heat exchange medium to flow out of the cylindrical tubular member 100. The cylindrical tubular member 100 has a tubular structure 15. Referring also to FIG. 1D, the exterior surface of the tubular structure 15 has a plurality of chamber assemblies 20 attached to the exterior surface of the tubular structure 15. Referring to FIG. 1C, the tubular structure 15 features a plurality of inlet orifices 30 and outlet orifices 35, to allow heat exchange medium to flow out of the tubular structure 15, and enter a chamber assembly 20, then allow the heat exchange medium to re-enter the tubular structure 15 from the chamber assembly 20 through the outlet orifice 35. Referring to FIG. 1C and FIG. 1D, the inlet orifice 30 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com