Framing members to enhance thermal characteristics of walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

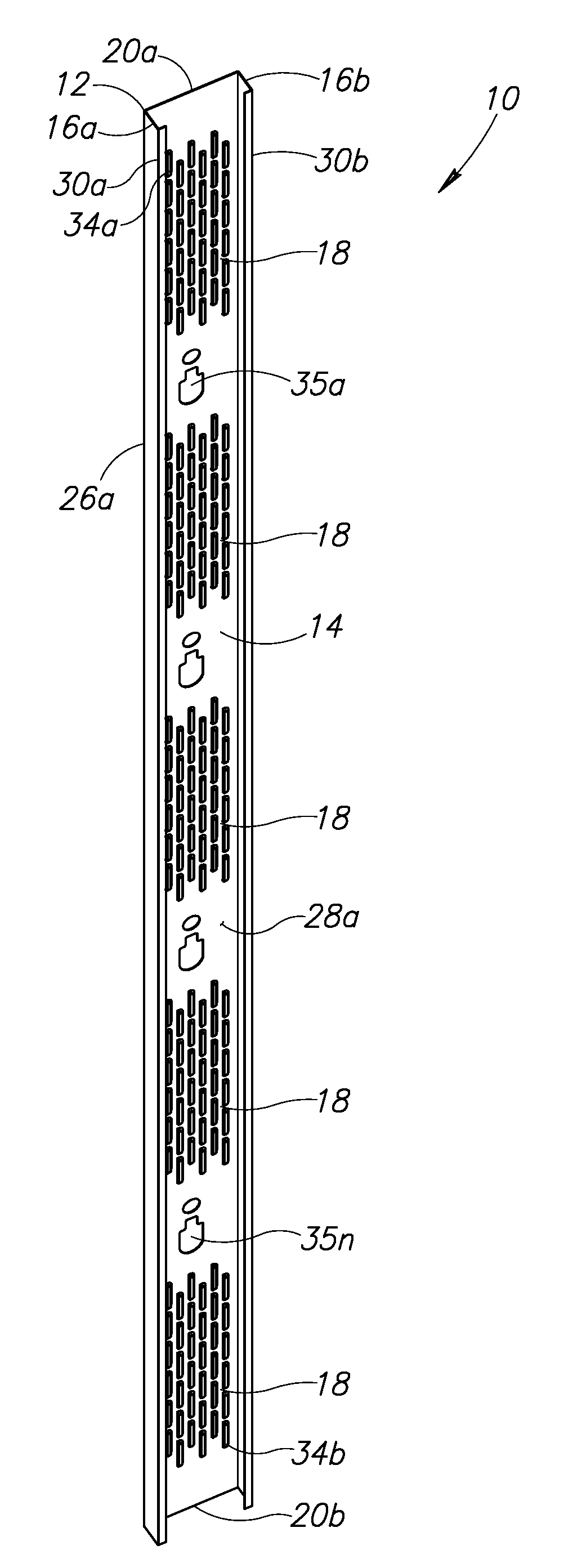

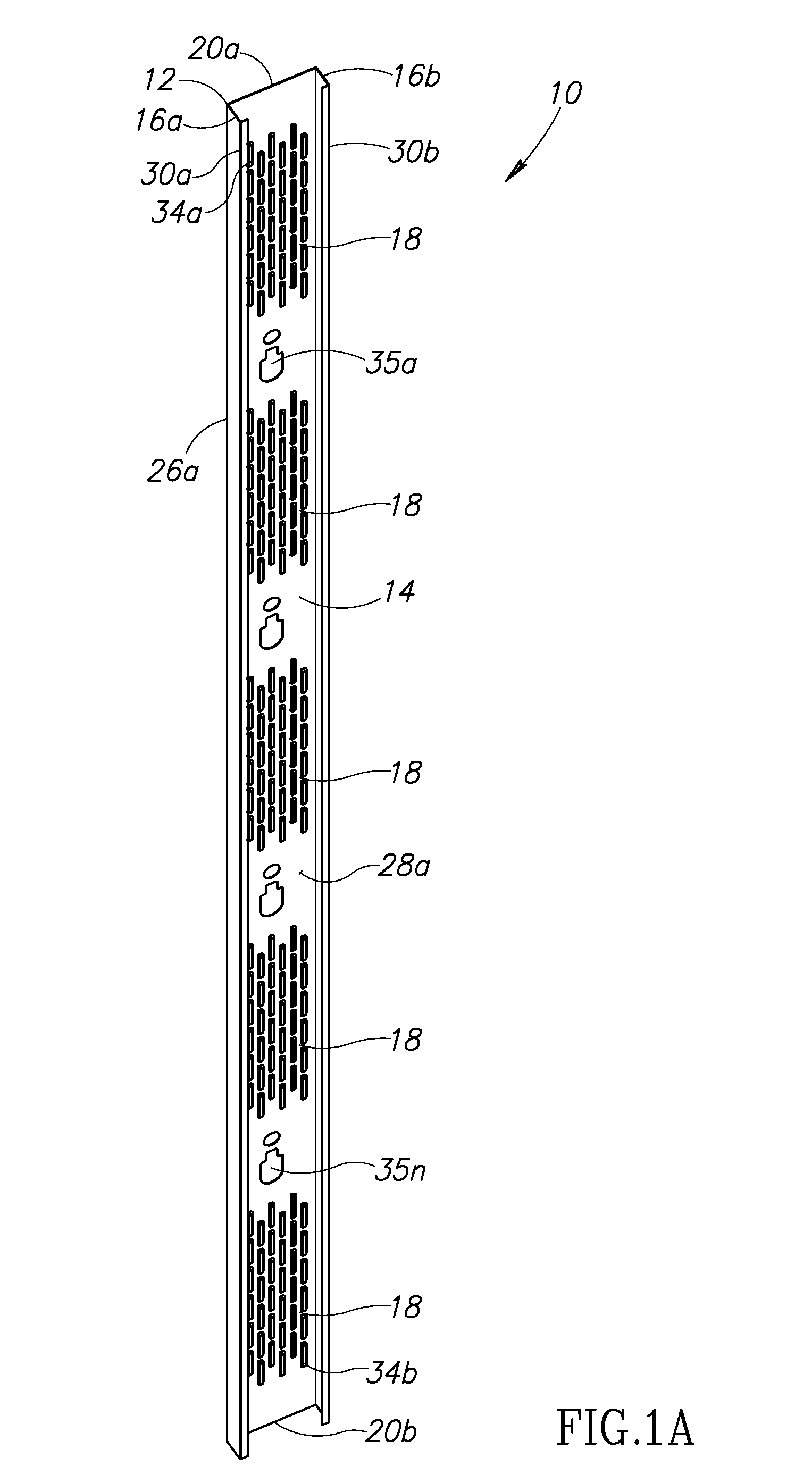

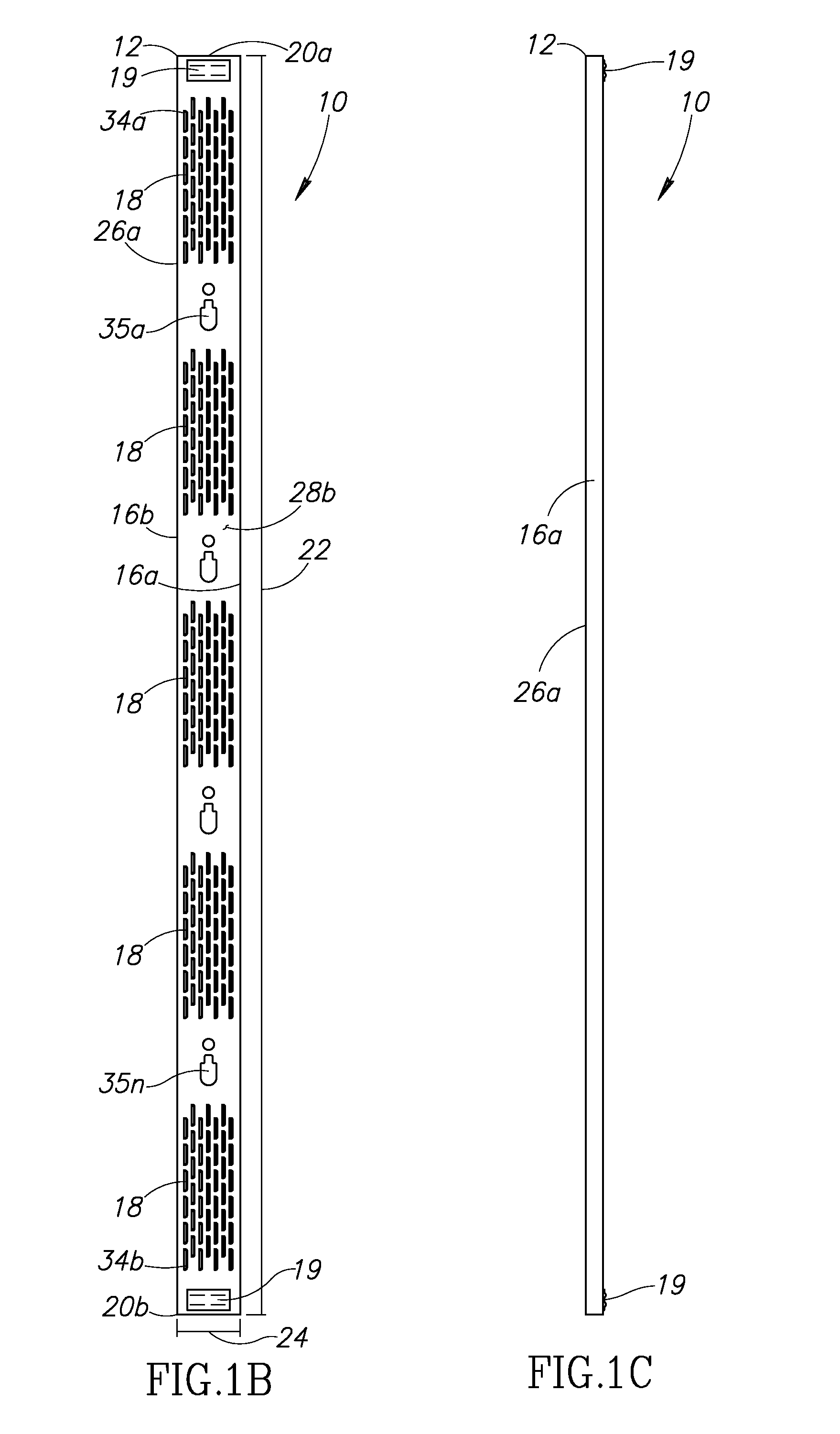

[0050]FIGS. 1A-1Eshow a structural or framing member in the form of a metal stud 10, according to one illustrated embodiment.

[0051]The metal stud 10 includes an elongated stud channel member 12 having a web or web portion 14 that includes a first (e.g. inner) major face 28a and a second (e.g., outer) major face 28b, and a pair of flanges 16a, 16b that along with the web portion 14 form a channel. As discussed below, the web portion 14 includes one or more sets of patterns of discontinuities 18, which contribute to the enhanced thermal performance of the metal stud 10.

[0052]The metal stud 10 has a first end 20a, a second end 20b opposed to the first end 20a across a length 22 (e.g., major length or major dimension illustrated in FIG. 1B) of the metal stud 10. The metal stud 10 has a width 24 that extends laterally across or perpendicularly to the length 22 of the metal stud 10.

[0053]The pair of flanges 16a, 16b extends from respective edges 26a, 26b of the web portion 14 at non-zero ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com