Closure Assembly Dosing-dispenser for Liquid Packaging Containers

a liquid packaging container and dosing device technology, applied in the field of improving liquid packaging system, can solve the problems of loss of tightness, lack of cooling means, cabinet sealing and tightness not guaranteed,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

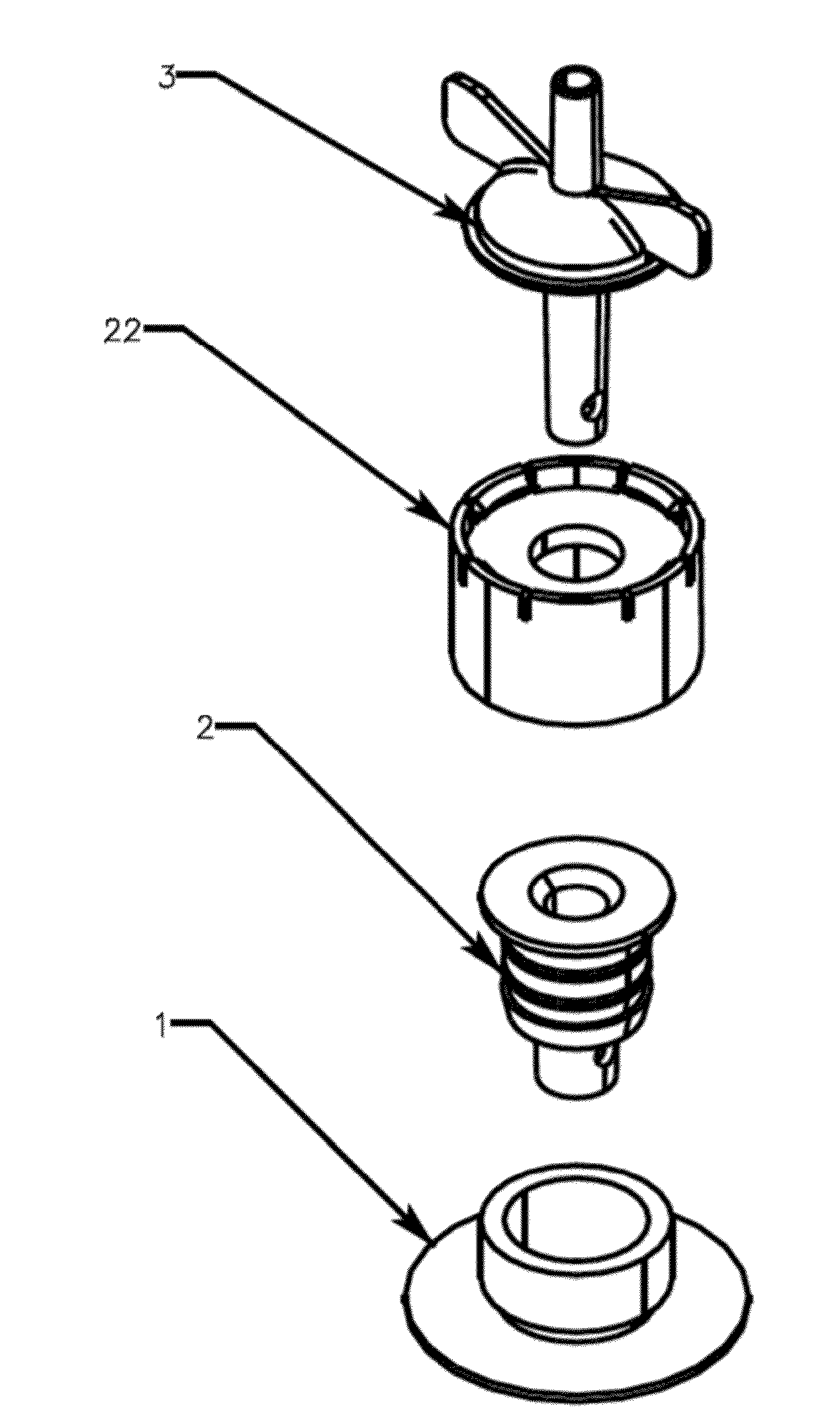

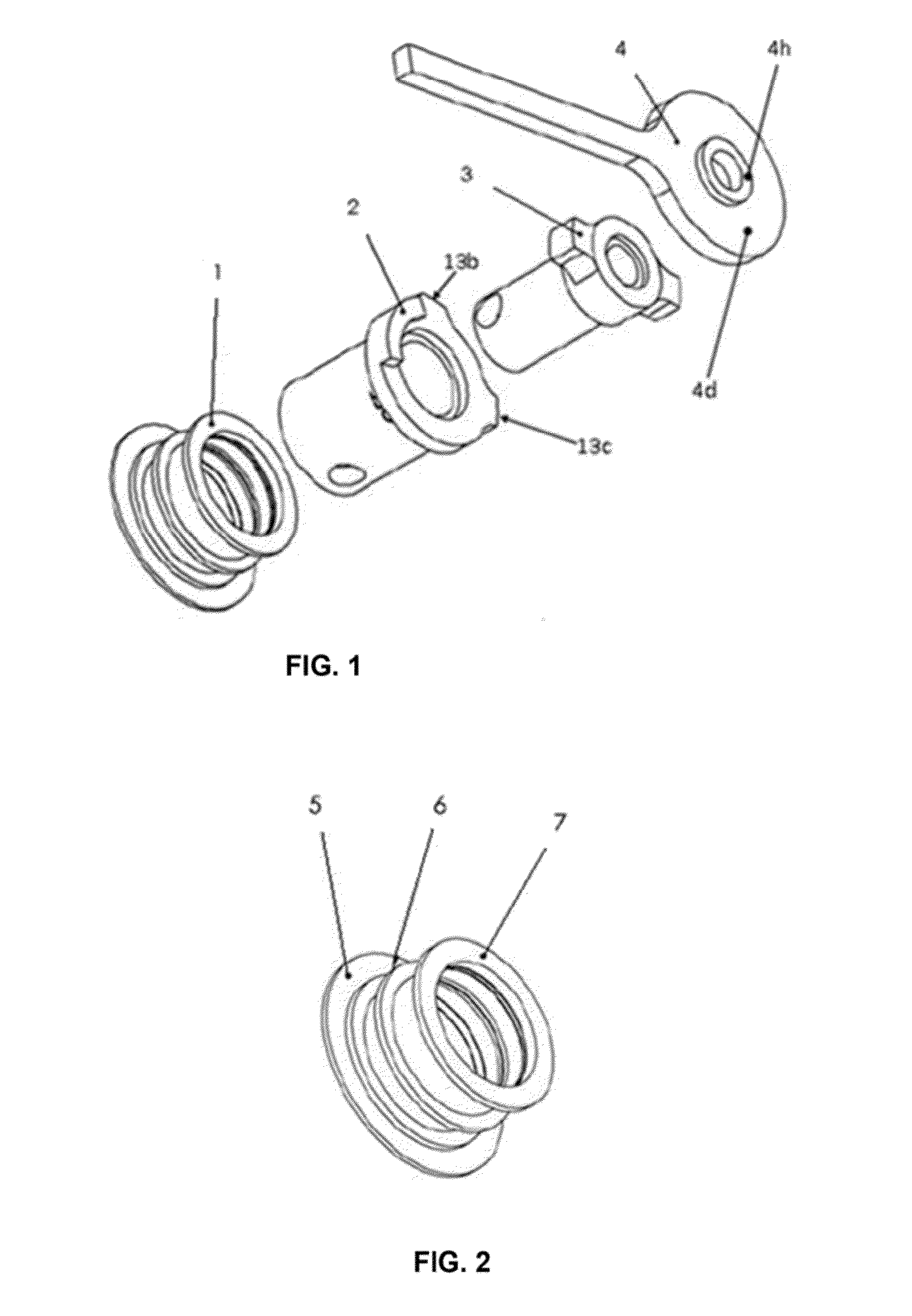

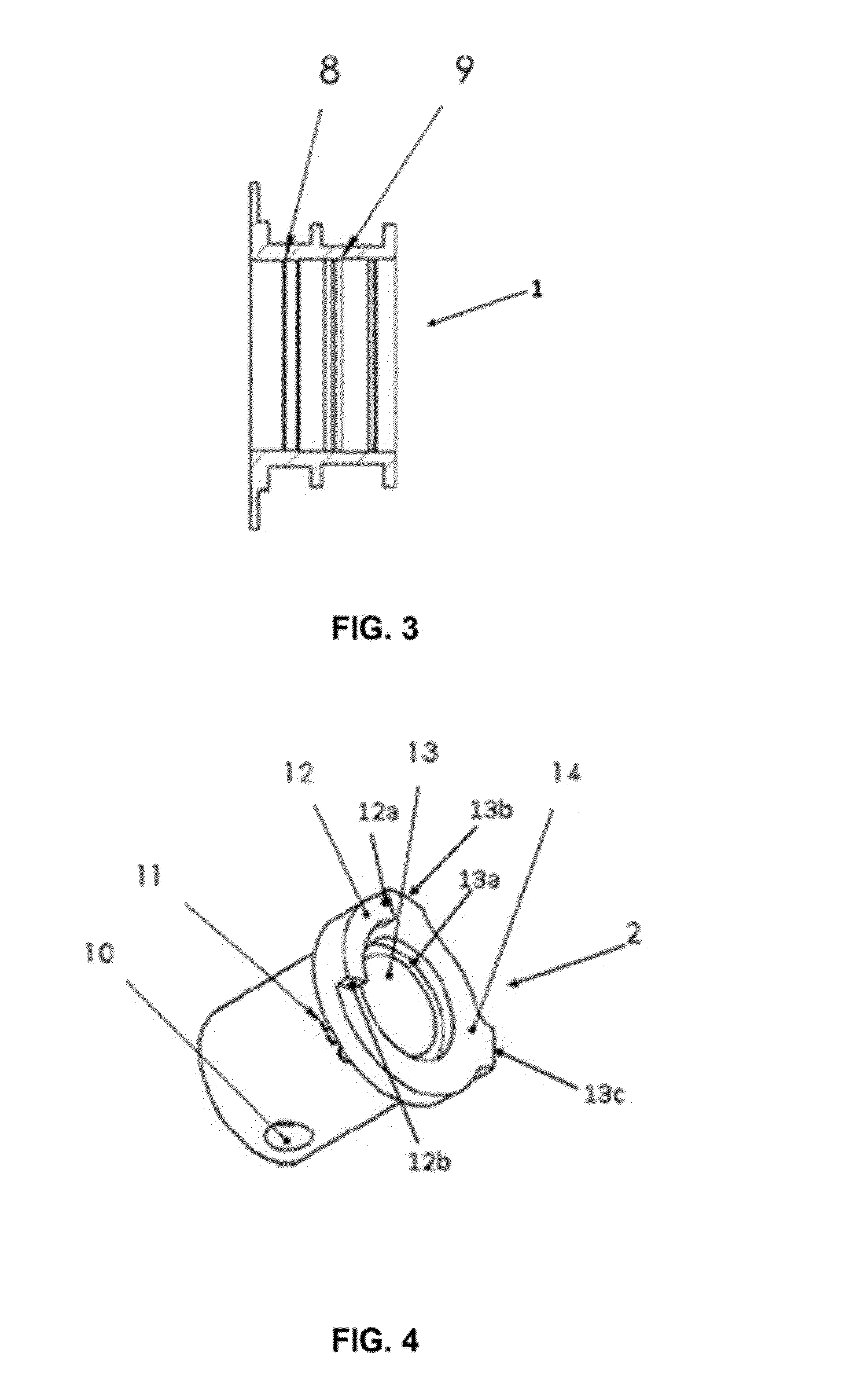

[0053]FIGS. 1-9 show a first preferred embodiment, FIGS. 10-15 show a second preferred embodiment and FIGS. 16-23 a third preferred embodiment of closure assembly dosing-dispenser for liquid packaging containers present description object, which comprises a hollow cylindrical female plug in which is inserted a hollow cylindrical male plug presenting the same axis of revolution than the female plug, and that it has the possibility of relative rotation with respect to the female plug whose inside determines the output liquid opening.

[0054]According to FIGS. 1-9, therein is depicted a closure assembly dosing-dispenser for all types of containers which contain liquids, which may comprise a mouthpiece (1), shown in FIGS. 2 and 3, which is attached to a container through a process of thermo-welded, threaded or other known attachment, enabling a seal between them.

[0055]The closure assembly has a female plug (2), shown in FIGS. 4 and 5, integral with the mouthpiece (1) or directly to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com