System and method of automated 3D scanning for vehicle maintenance

a technology of automatic vehicle maintenance and system and method, applied in the field of system and method of automated vehicle problem diagnosis and maintenance, can solve the problems of low brake fluid, and low oil or water level, and achieve the effect of convenient opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

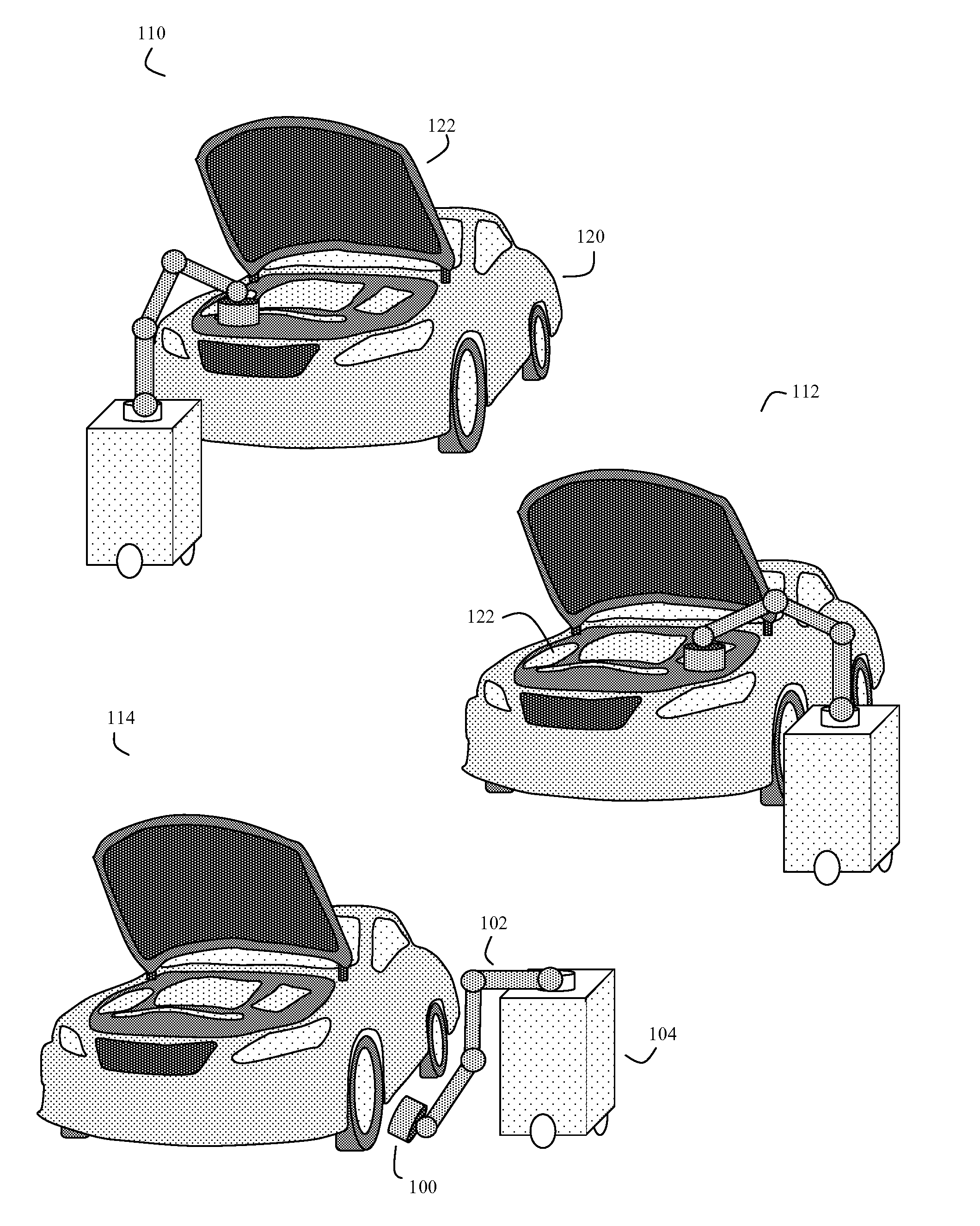

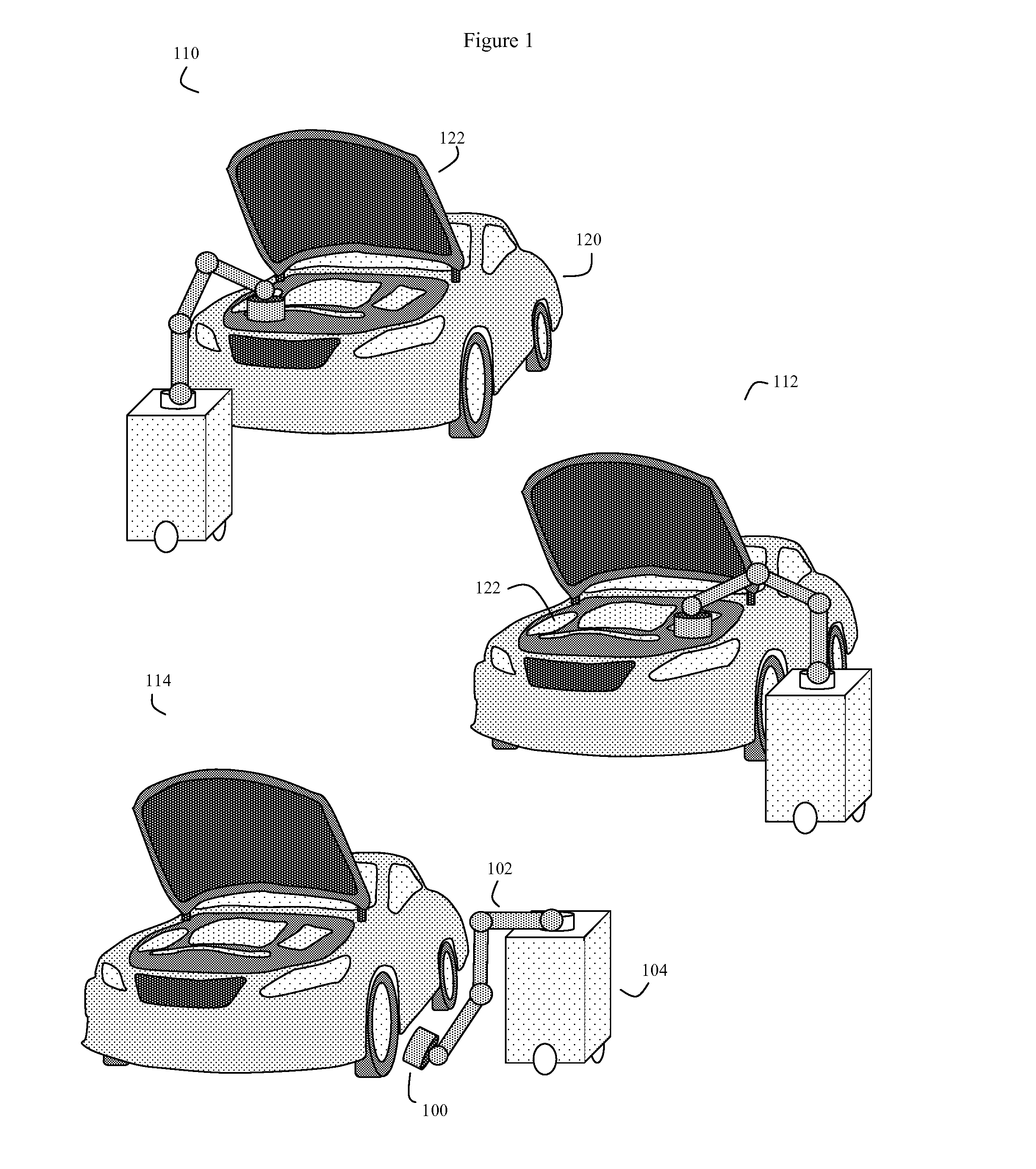

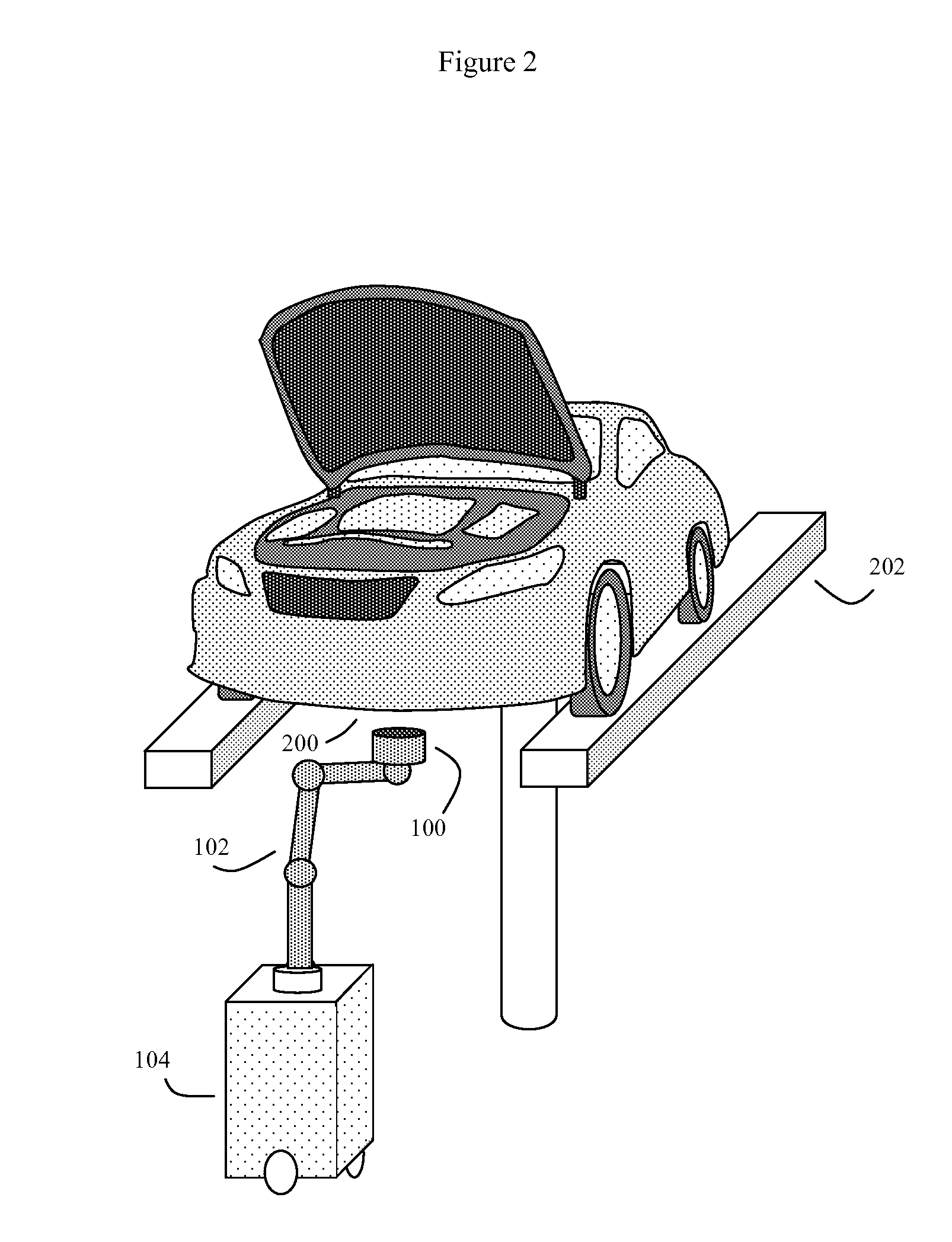

[0029]It is envisioned that in normal operation, the invention will be used to scan and assess the state of multiple mechanical components of an intact or substantially intact vehicle, rather than simply scan and assess individual mechanical components while the components are isolated from the vehicle. Mechanical components are 3D objects that, at least in isolation, have various exposed surfaces. However because the system is scanning an intact or substantially intact vehicle, not all surfaces of all vehicle mechanical components will be exposed. Instead, some mechanical components will be hidden entirely (all surfaces hidden), while some mechanical components will only have some of their various surfaces available for scanning.

[0030]Some limited exposure of hidden components, such as by moving access panels, or even removing a few blocking components, is contemplated, however. Automobiles, for example, usually have various engine components hidden by a moveable hood, which can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com