Structure of laser sight

a laser sight and structure technology, applied in the direction of sighting devices, weapons, weapon components, etc., can solve the problems of inability to apply laser sight according to the prior art to different types of guns, increase in cost, inconvenience in use, etc., and achieve the effect of improving the structure of laser sigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

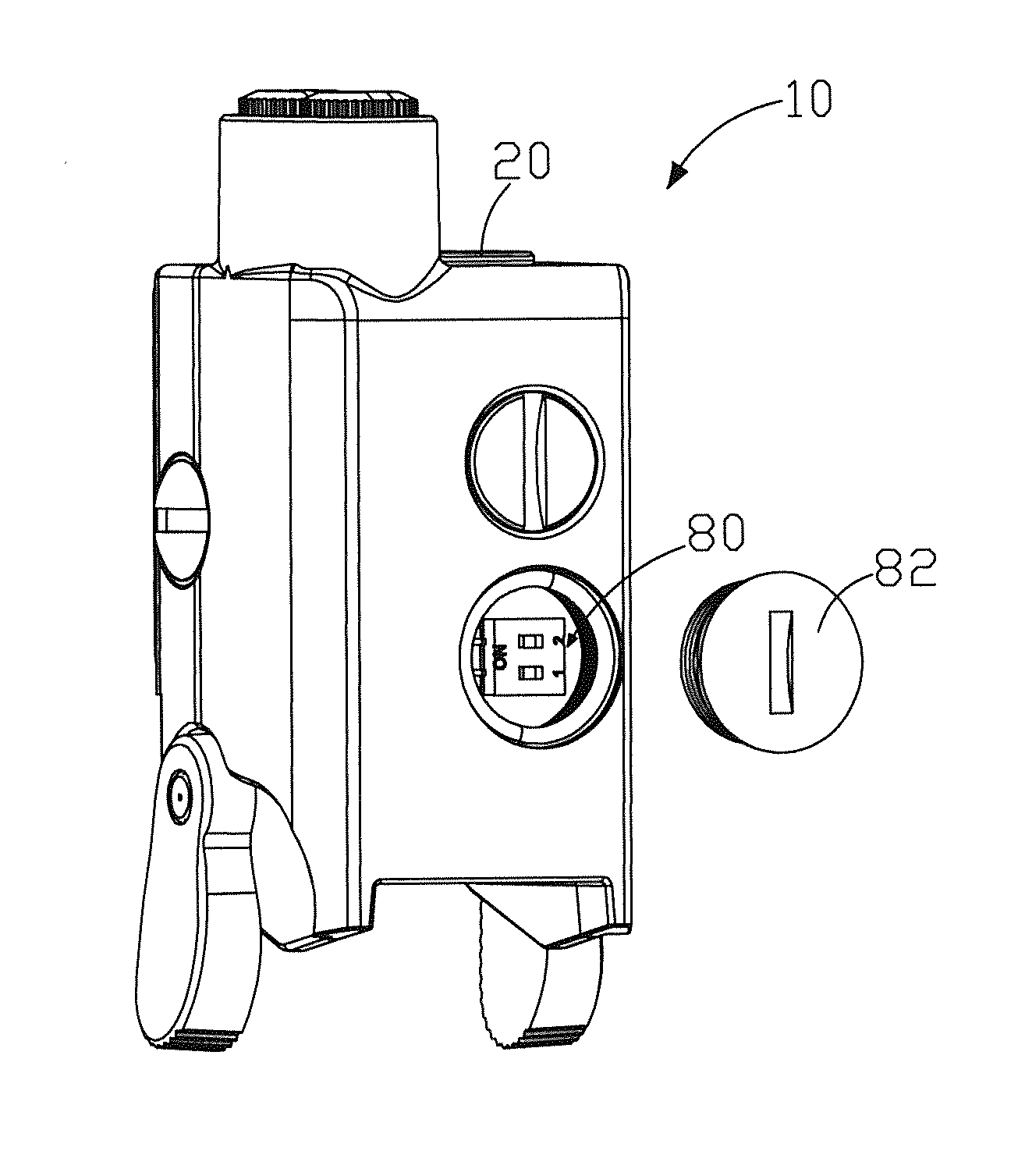

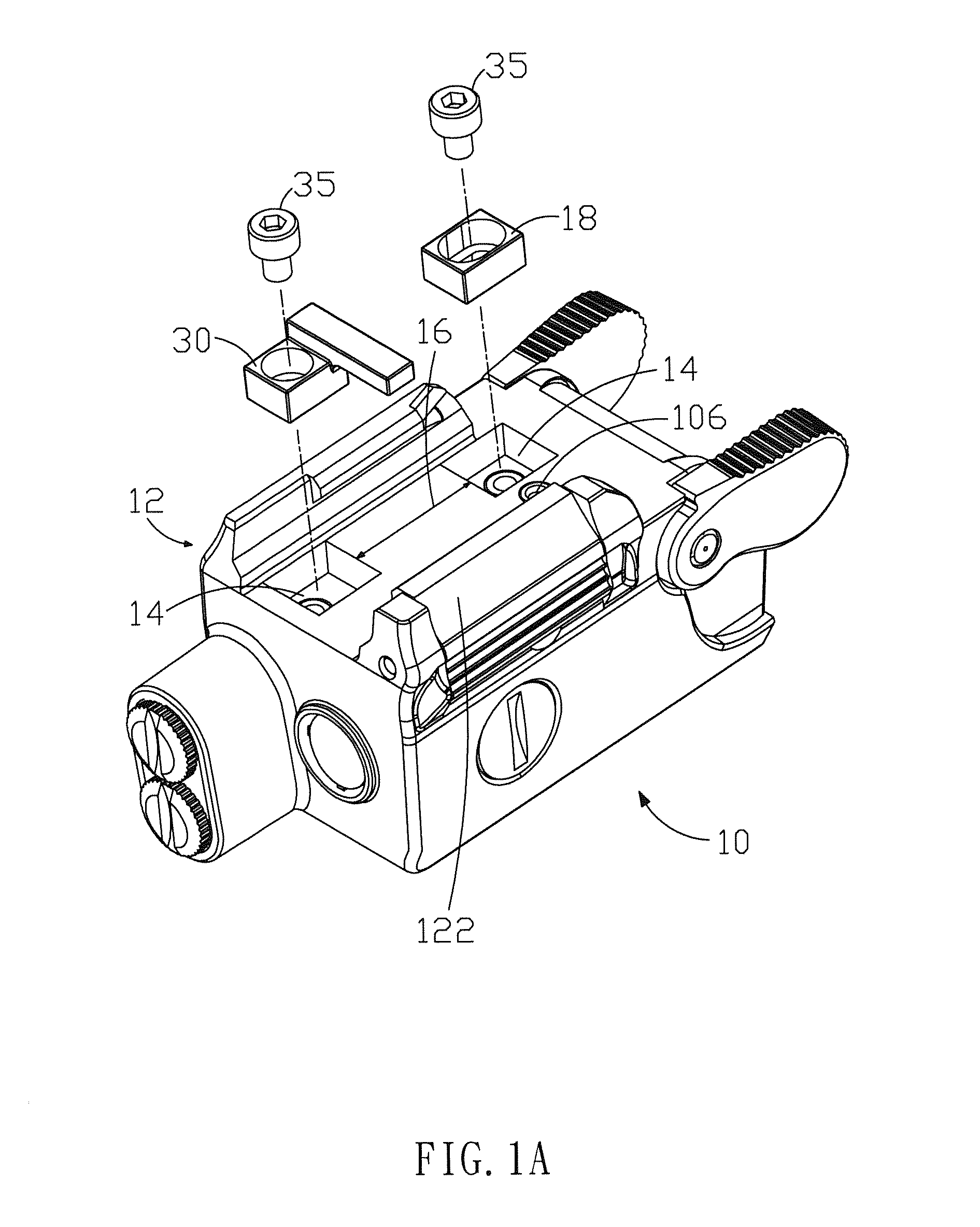

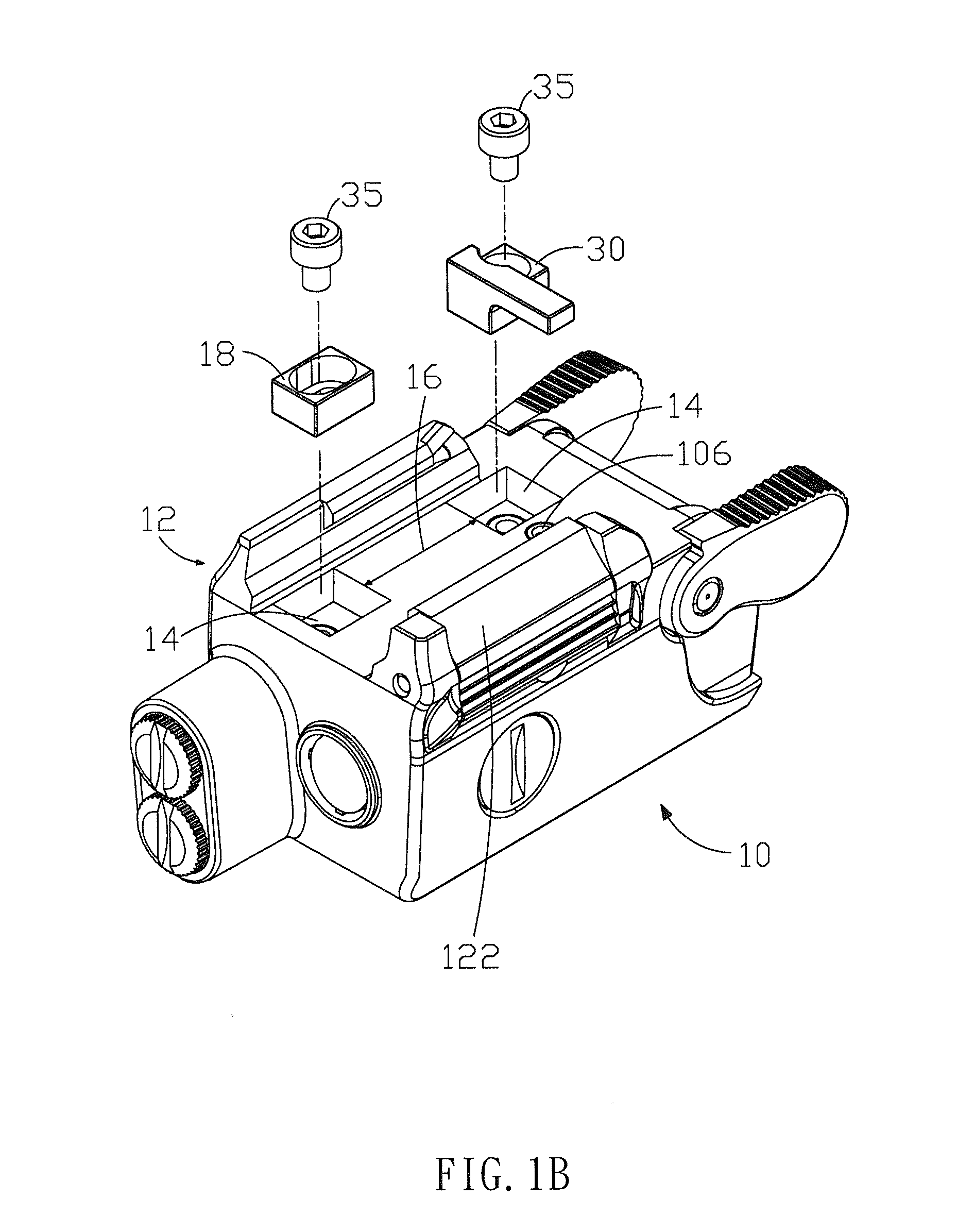

[0027]First, please refer to FIGS. 1A, 1B, and 2, which show exploded views (1), (2) and a top view of the structure according to the present invention. As shown in the figures, the present embodiment comprises a sight body 10, a block 30, and a plurality of fixing members 35. The sight body 10 has a clamping track 12 and two positioning trenches 14 on one side. The two positioning trenches 14 are disposed between two guiders 122 of the clamping track 12. Besides, there is a spacing 16 between the two positioning trenches 14 adjustable according to the type of firearms. The block 30 is disposed at the positioning trench 14. The plurality of fixing members 35 are fixed and locked in the positioning trenches 14 and position the block 30 in the positioning trench 14.

[0028]Please refer to FIG. 3, which shows an internal schematic diagram according to the first embodiment of the present invention. As shown in the figure, the clamping track 12 includes two guiders 122 and an elastic devic...

second embodiment

[0031]Please refer to FIG. 6 and FIG. 7, which show an external view and an internal view of the structure according to the present invention. As shown in the figure, the present embodiment comprises a sight body 10, a first adjuster 50, a first displacement detector 55, a second adjuster 60, and a second displacement detector 65. The sight body 10 has a laser module 20 therein. The first adjuster 50 includes a first knob 502, a first push member 504, and a first elastic member 506. The first knob 502 is disposed on one side of the sight body 10. The first knob 502 has a plurality of scale grooves 5021 on one side. The first push member 504 is disposed inside the sight body 10. One end of the first push member 504 is connected with the first knob 502 while the other end thereof is disposed against the laser module 20. The first elastic member 506 corresponds to the first push member 504 and is disposed on one side of the laser module 20. The first displacement detector 55 includes a...

third embodiment

[0036]Please refer to FIG. 8, FIG. 9, and FIG. 10, which show an exploded view and functional diagrams (1), (2) of the switch according to the present invention. As shown in the figures, the present embodiment comprises a sight body 10 and a switch 70. The sight body 10 has a circuit module 90 therein. The circuit module 90 includes a circuit board 92 and a conductive member 94. The circuit board 92 is connected electrically with a laser module (not shown in the figures); the conductive member 94 is connected electrically with the circuit board 92. The switch 70 includes two handles 72, a link 74, a conductive part 76, and a unidirectional torque spring 78. The two handles 72 are disposed on both sides of the sight body 10, respectively. The link 74 is disposed pivotally inside the sight body 10 with both ends connected with the two handles 72, respectively. The conductive part 76 is disposed at the link 74 and corresponding to the conductive member 94. The conductive part 76 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com