Wood Golf Club Head and Method for Manufacturing the Same

a golf club head and wood technology, applied in the field can solve the problems of disadvantageously reducing the yield rate deformation of the club head body, etc., and achieve the effects of improving the structural strength of wood golf club heads, reducing the impact of external forces, and dispersing smoothly through the pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

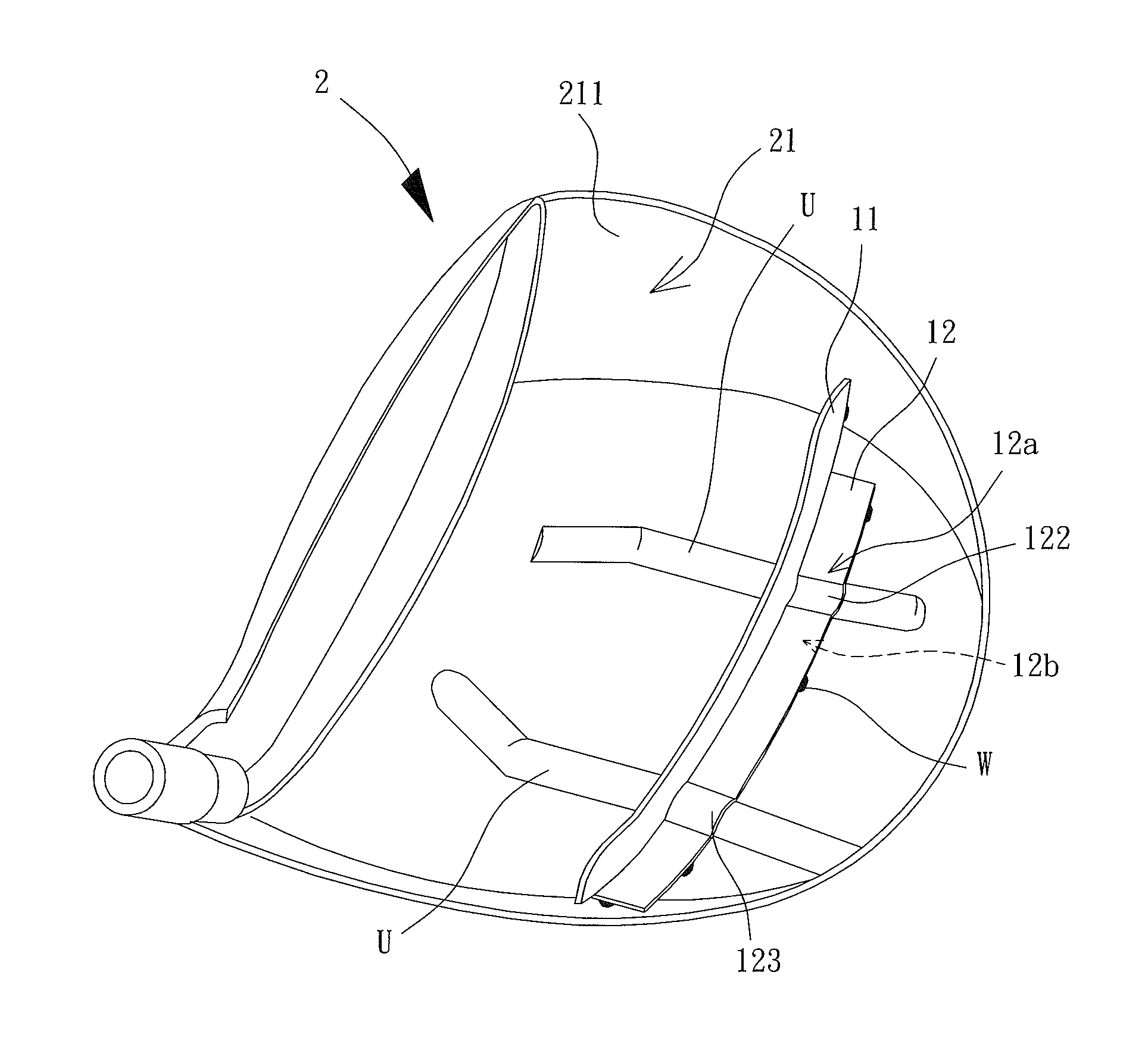

[0025]A method for manufacturing a wood golf club head according to the present invention includes disposing a reinforcing member 1 in the wood golf club head to reduce the impact of an external force acting upon the wood golf club head and to improve the structural strength of the wood golf club head.

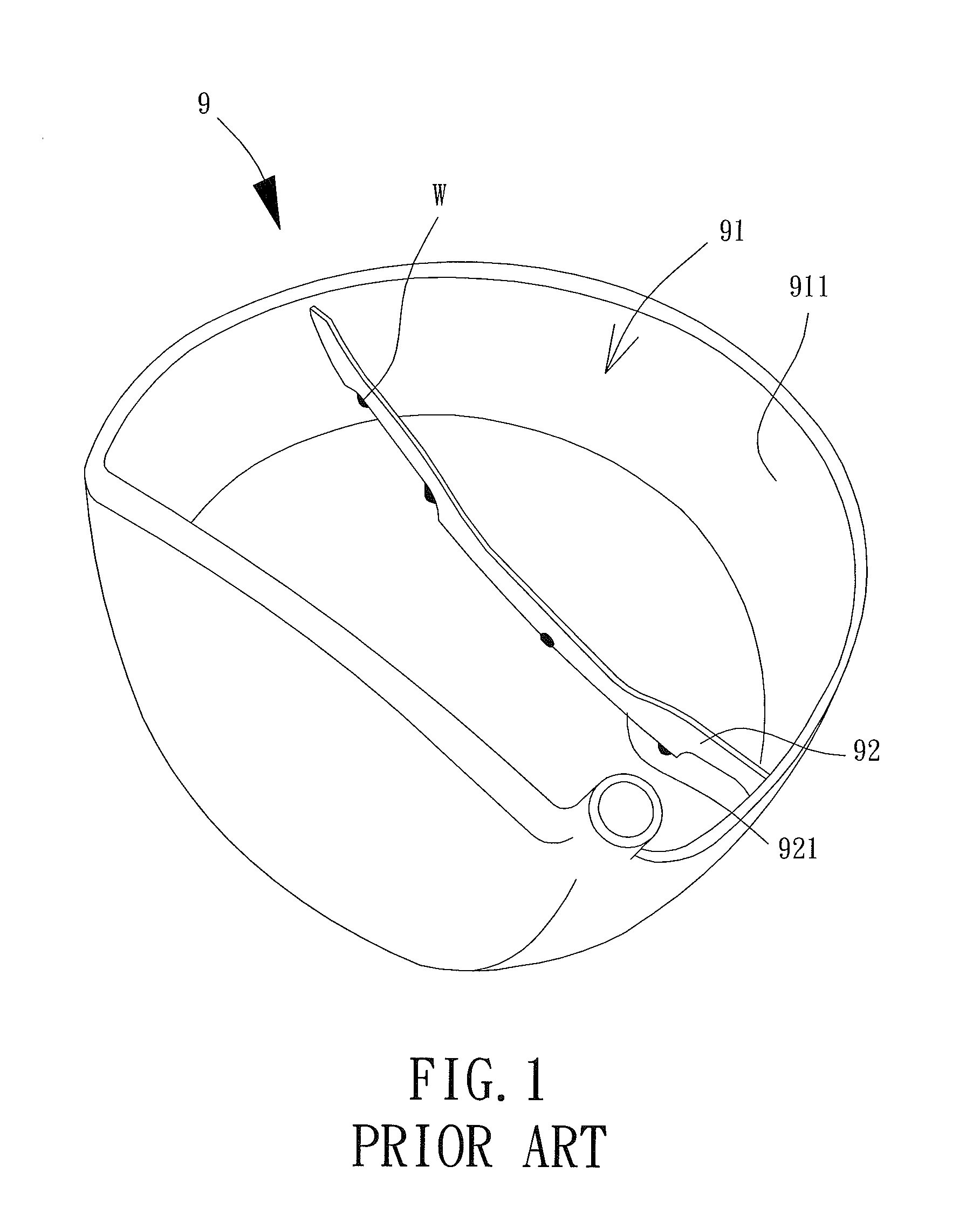

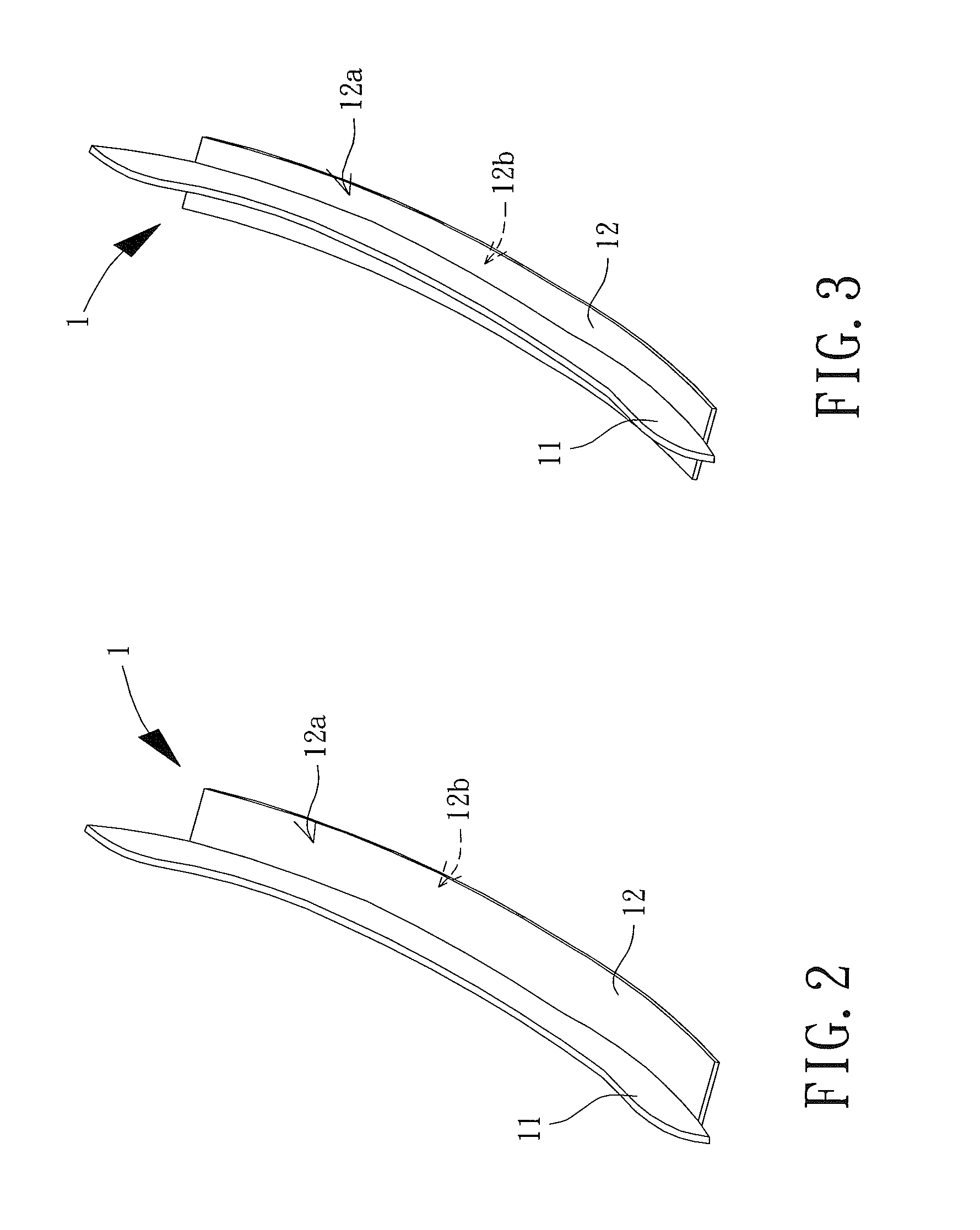

[0026]With references to FIGS. 1 and 2, the reinforcing member 1 includes a rib 11 and a pad 12. The rib 11 is narrow and long and has two opposite sides and two opposite ends. The two opposite ends of the rib 11 may abut with an inner surface of the wood golf club head. The pad 12 is also narrow and long and has two opposite sides, a connecting surface 12a, and a welding surface 12b opposite to the connecting surface 12a. One of the two sides of the rib 11 is connected with the connecting surface 12b of the pad 12. Preferably, the pad 12 has a thickness of 0.1 to 5 mm between the connecting surface 12a and the welding surface 12b, and a width of 2 to 30 mm (namely, the width of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com