Systems and Methods for Catastrophe Mitigation for Deep Water Oil Drilling during Blowout Preventer Failure

a technology of deep water oil drilling and catastrophe mitigation, which is applied in the field of subsea blowout preventers, can solve the problems of limited barrier between the rig and workers, no remedy for the failure mechanism of the failed bop, etc., and achieve the effect of minimizing the duration of spill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

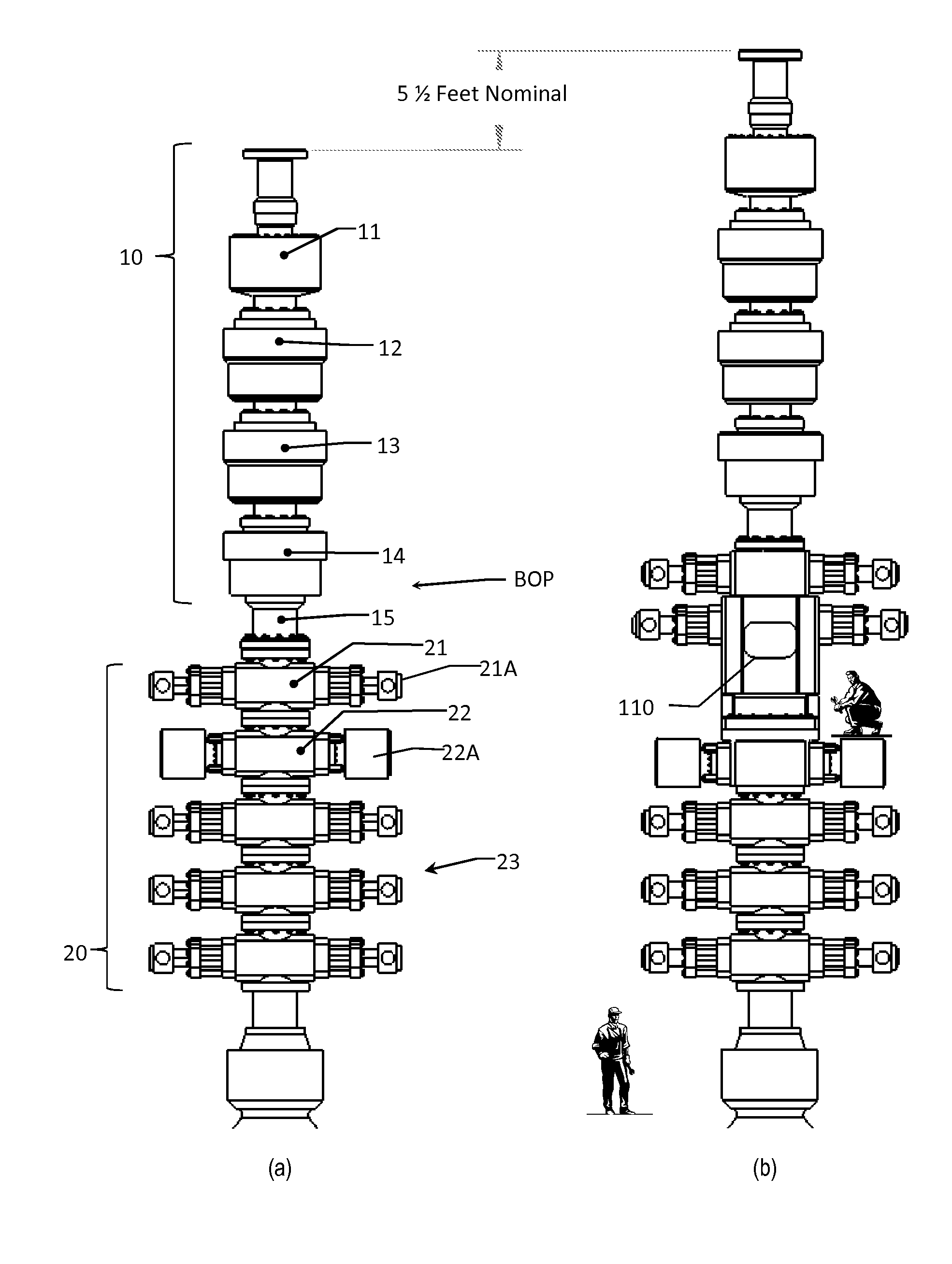

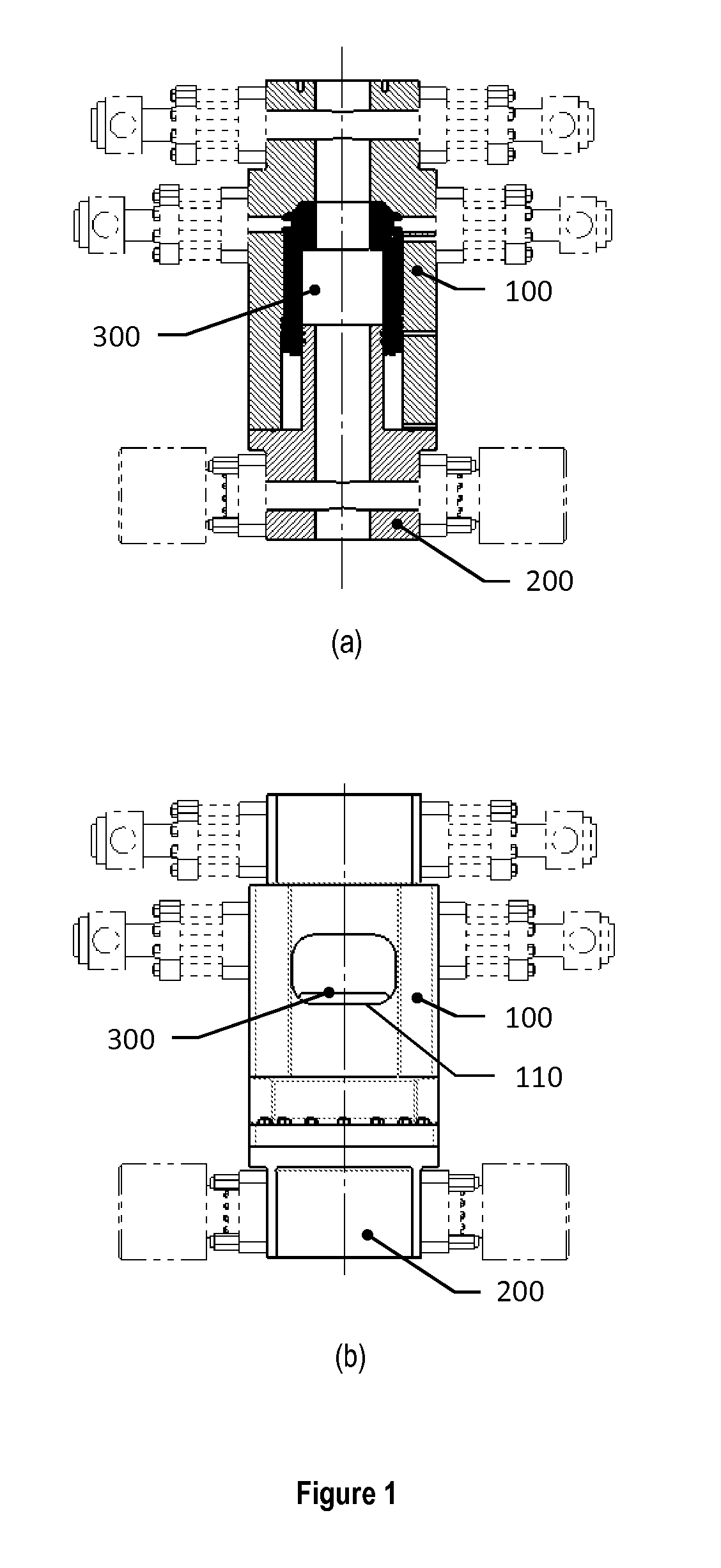

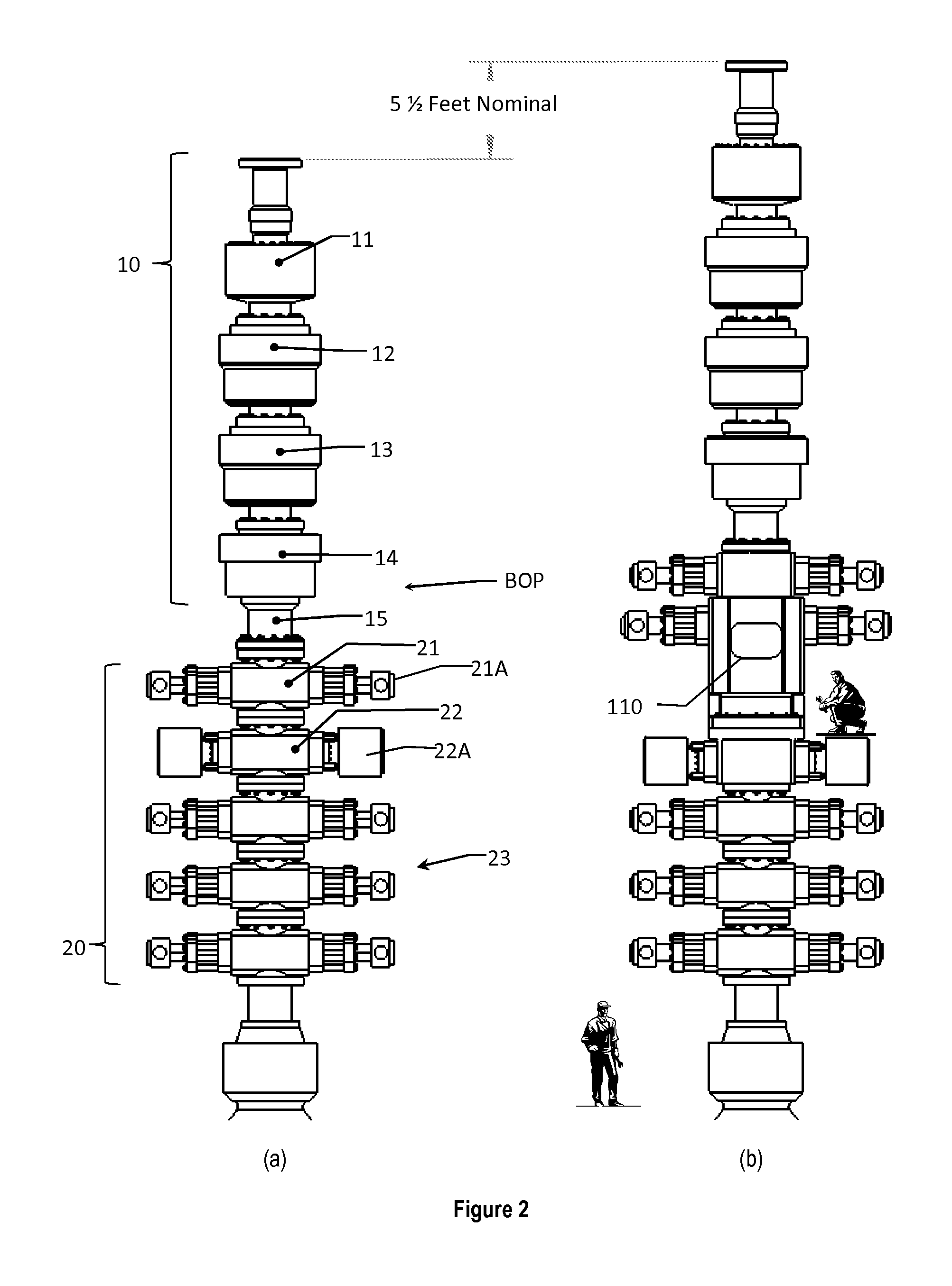

[0032]Embodiments of the present disclosure will be described more fully hereinafter with reference to the accompanying drawings in which like numerals represent like elements throughout the several figures, and in which example embodiments are shared. Embodiments of the claims may, however, be embodied in many different forms and should not be construed to be limited to the embodiments set forth herein. The examples set forth herein are non-limiting examples, and are merely examples among other possible examples. System parts are indicated by leader lines with arrowheads pointing to the part, or leader lines with dots touching the part. Part features, such as surfaces, embossments, debossments, or similar are indicated by leader lines only, touching the feature. The system disclosed herein integrates with existing systems. 3-digit numerals are used to represent elements of the invention. 2-digit numerals represent elements of existing machinery with which the invention integrates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com