Turbomachine having a temperature-controlled cover

a technology of temperature control and turbine, which is applied in the direction of machines/engines, engine starters, liquid fuel engines, etc., can solve the problems of unsatisfactory heating of bearing lubrication oil, drawbacks with respect to seals, and gap growth, so as to achieve effective shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

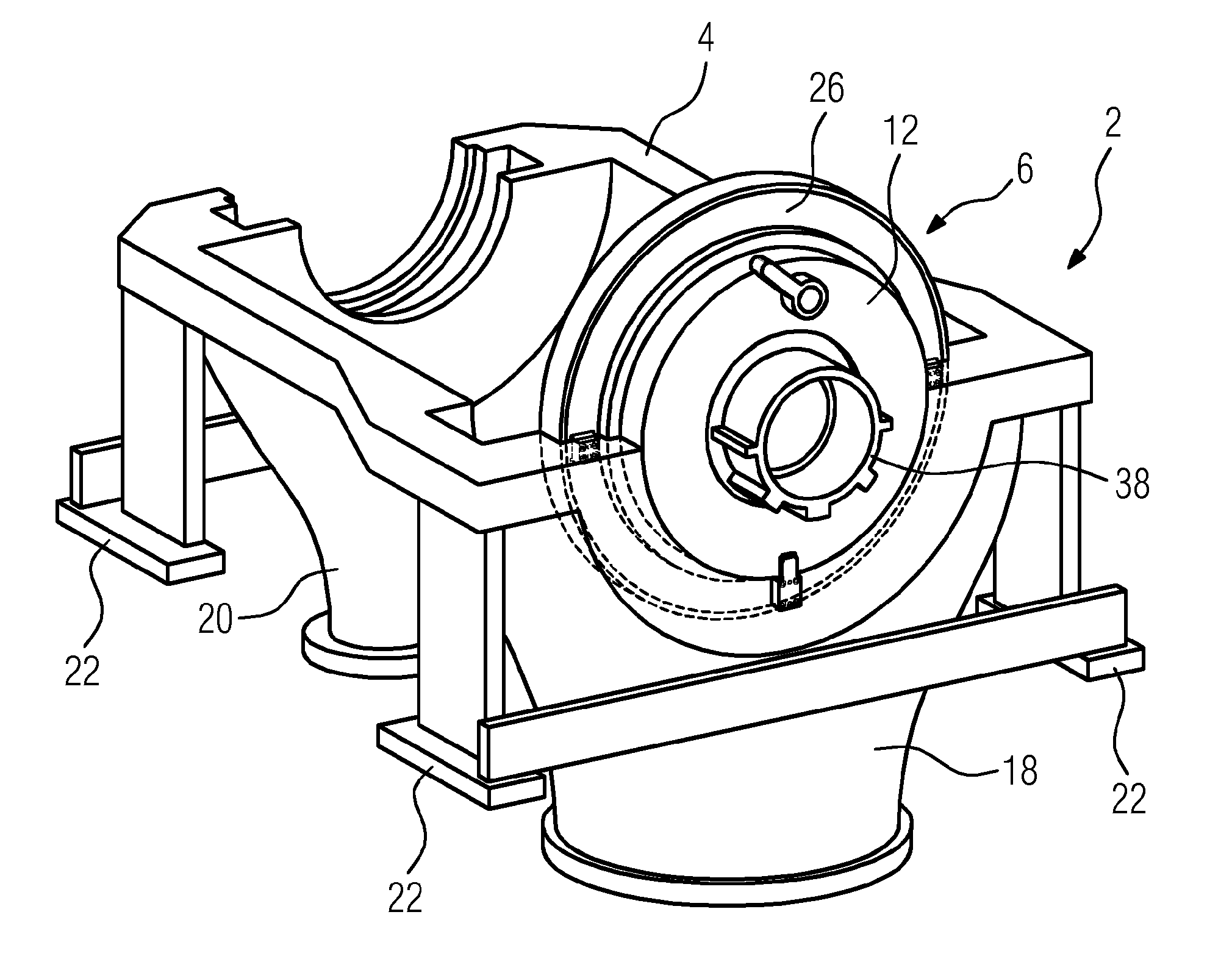

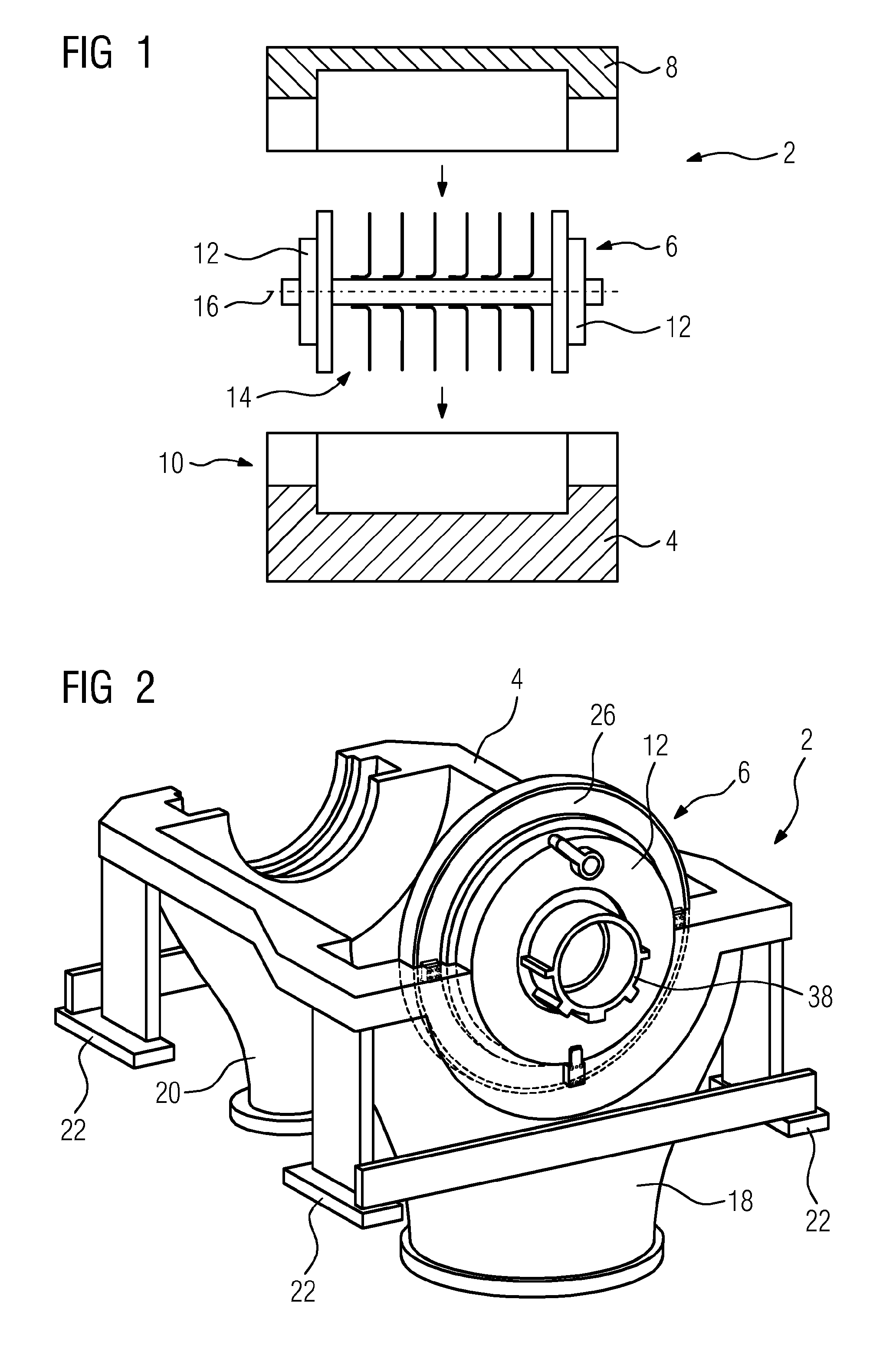

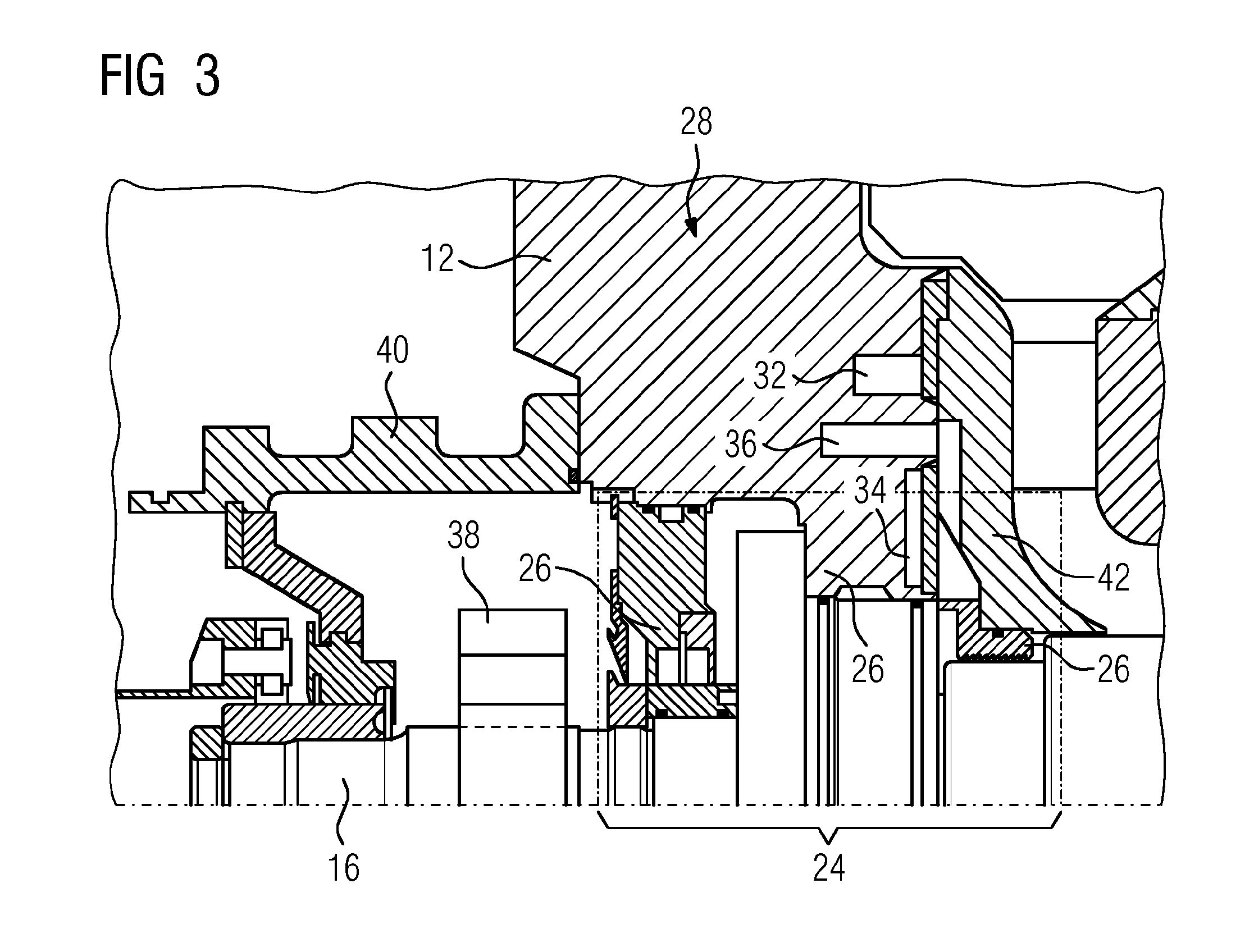

[0031]In large turbomachines, the housing is divided into a lower housing part and an upper housing part. In order to assemble the turbomachine, first of all the lower housing part is set up and then a rotor assemblage is inserted from above into the lower housing part. This is schematically illustrated in FIG. 1. The lower housing part 4 of the turbomachine 2 stands on a solid underlying surface and the assemblage 6 is lowered from above into the lower housing part 4. Subsequently, the upper housing part 8 is placed onto the lower housing part 4 and screwed together therewith, resulting in the overall housing 10. The assemblage is surrounded by the housing 10, wherein two covers 12 of the assemblage 6 remain visible from the outside and can also be designated part of the housing 10. The two covers 12 are in turn connected to the rotor 14, the shaft 16 of which is guided through the two covers 12 and is sealed off in the two covers 12 by way of a shaft seal (not illustrated). The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com