Integrated production simulator based on capacitance-resistance model

a production simulator and capacitance resistance technology, applied in the field of integrated production simulators based on capacitance resistance models, can solve the problems of prohibitively slow, prohibitively slow for use in supporting day-to-day decisions related to production optimization, and large computer resources to run

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

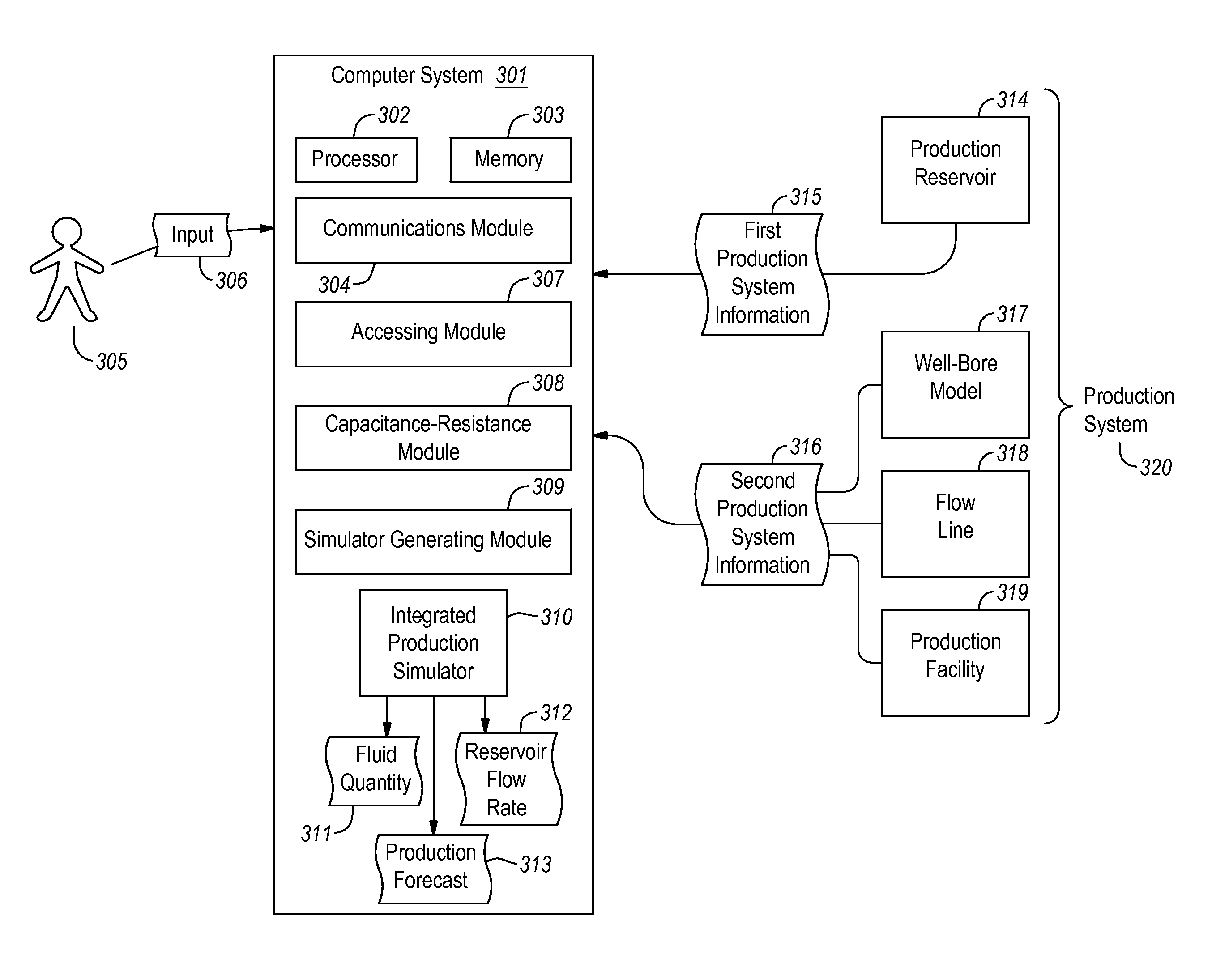

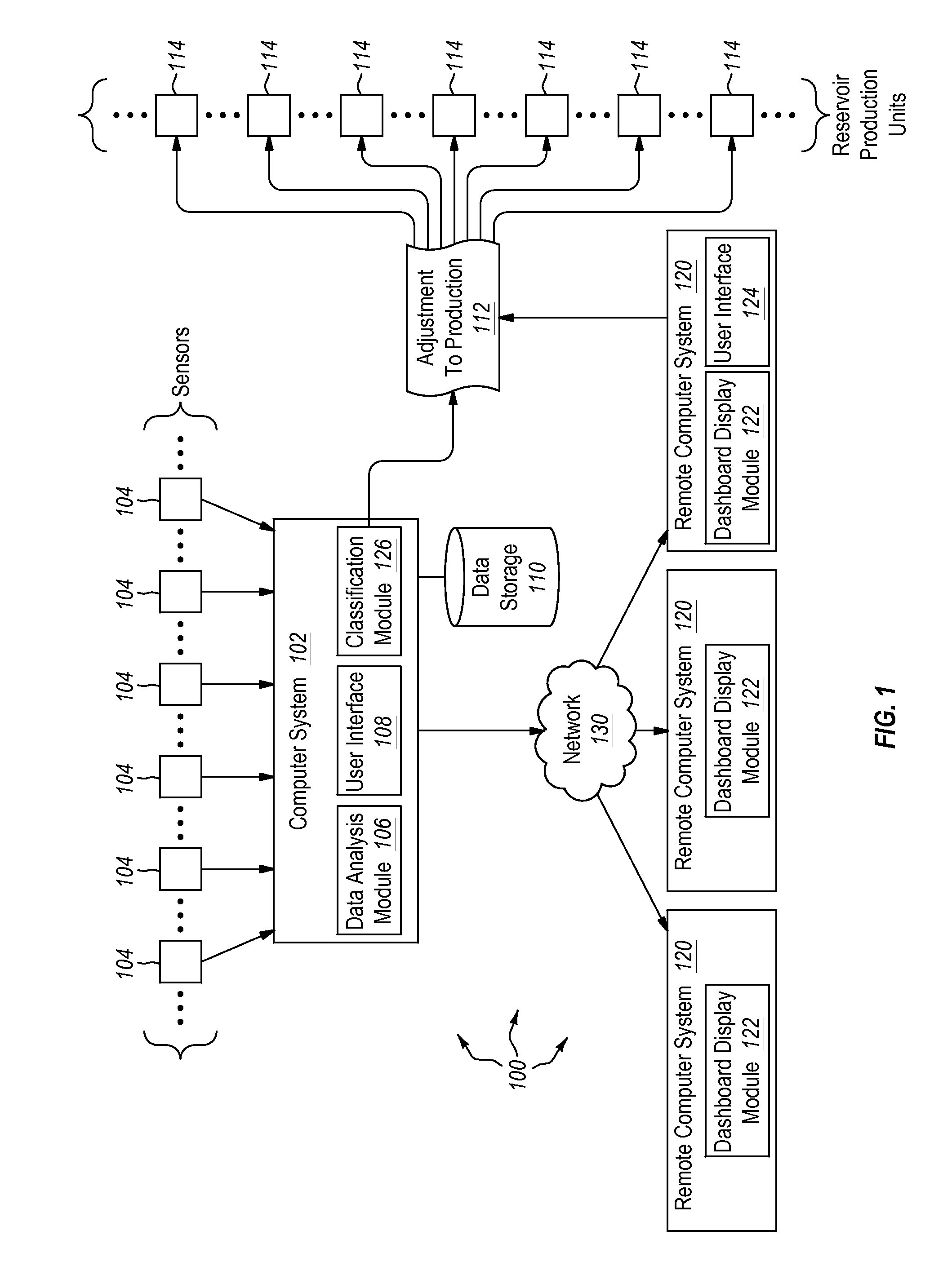

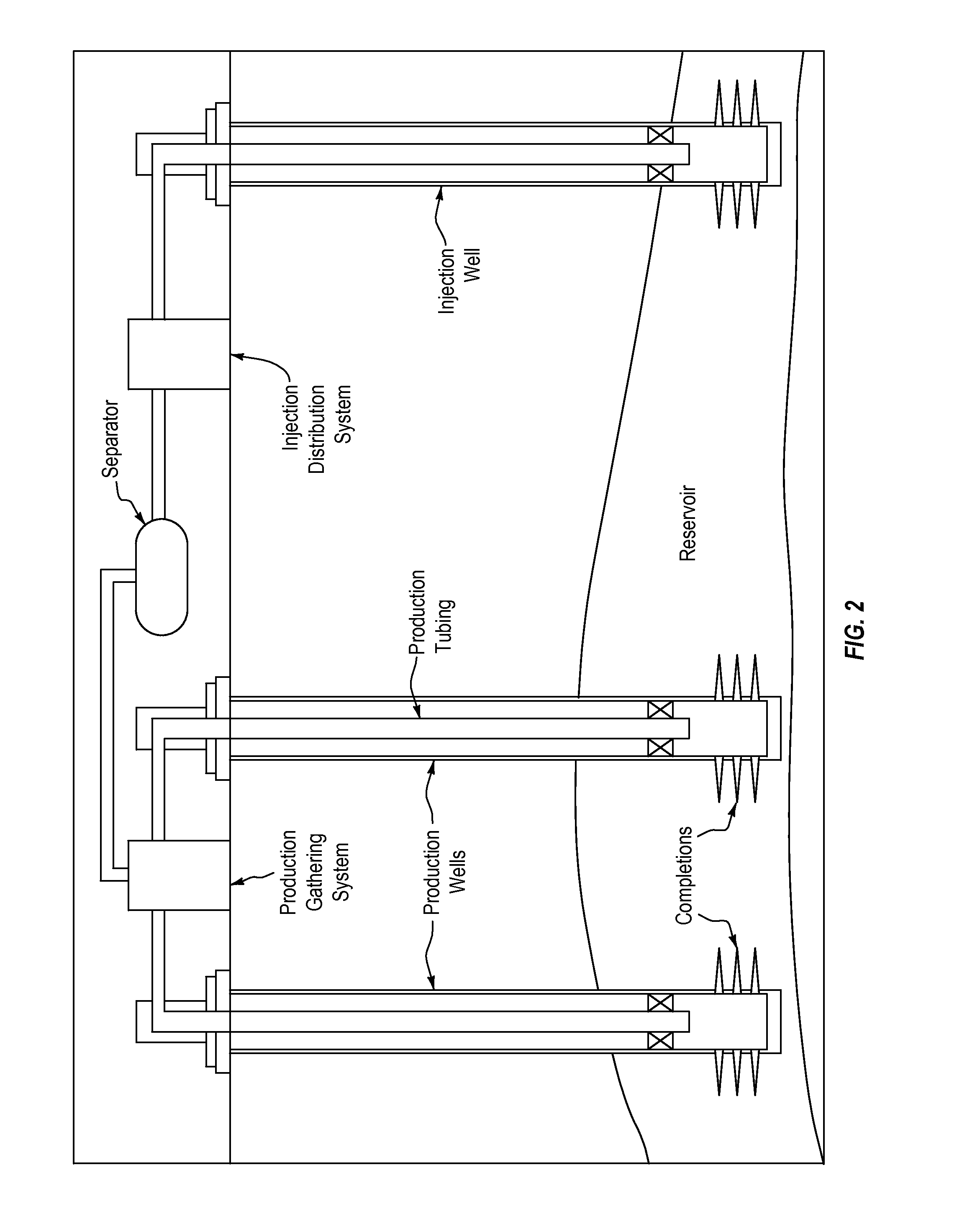

[0022]Embodiments described herein are directed to modeling a production system and to generating a production forecast for individual wells. In one embodiment, a computer system accesses portions of first production system information from a capacitance-resistance model of the production system, where the production system corresponds to a production reservoir. The computer system further accesses portions of second production system information from a well-bore model, a flow line and / or a production facility. The computer system then generates an integrated production simulator using both the first and second accessed production systems information, and implements the integrated production simulator to determine the quantity of fluids produced per phase over time as a function of operational field parameters corresponding to the production system by identifying the flow rate for the production reservoir.

[0023]In another embodiment, an integrated well-based production simulator sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com