A Toilet Including a Water Trap Having a Conical Part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

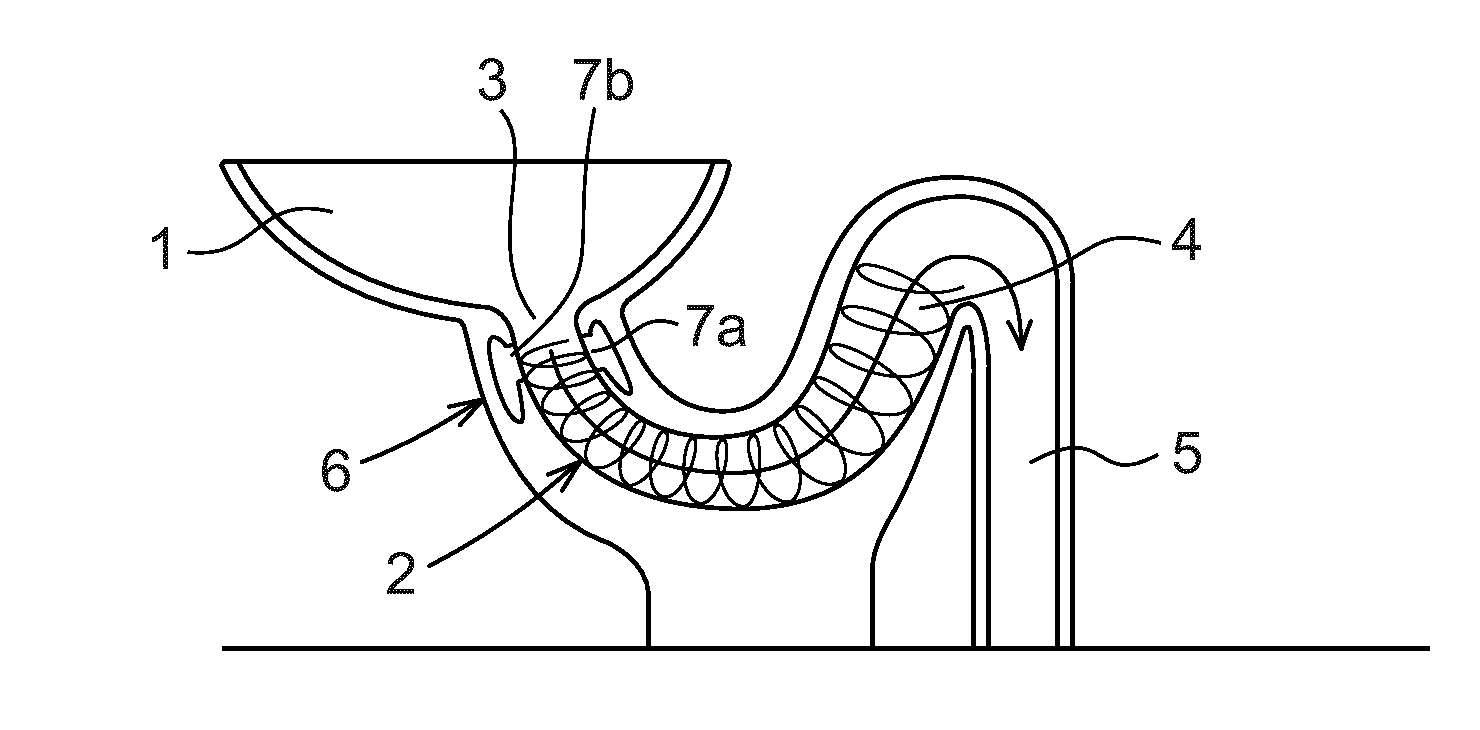

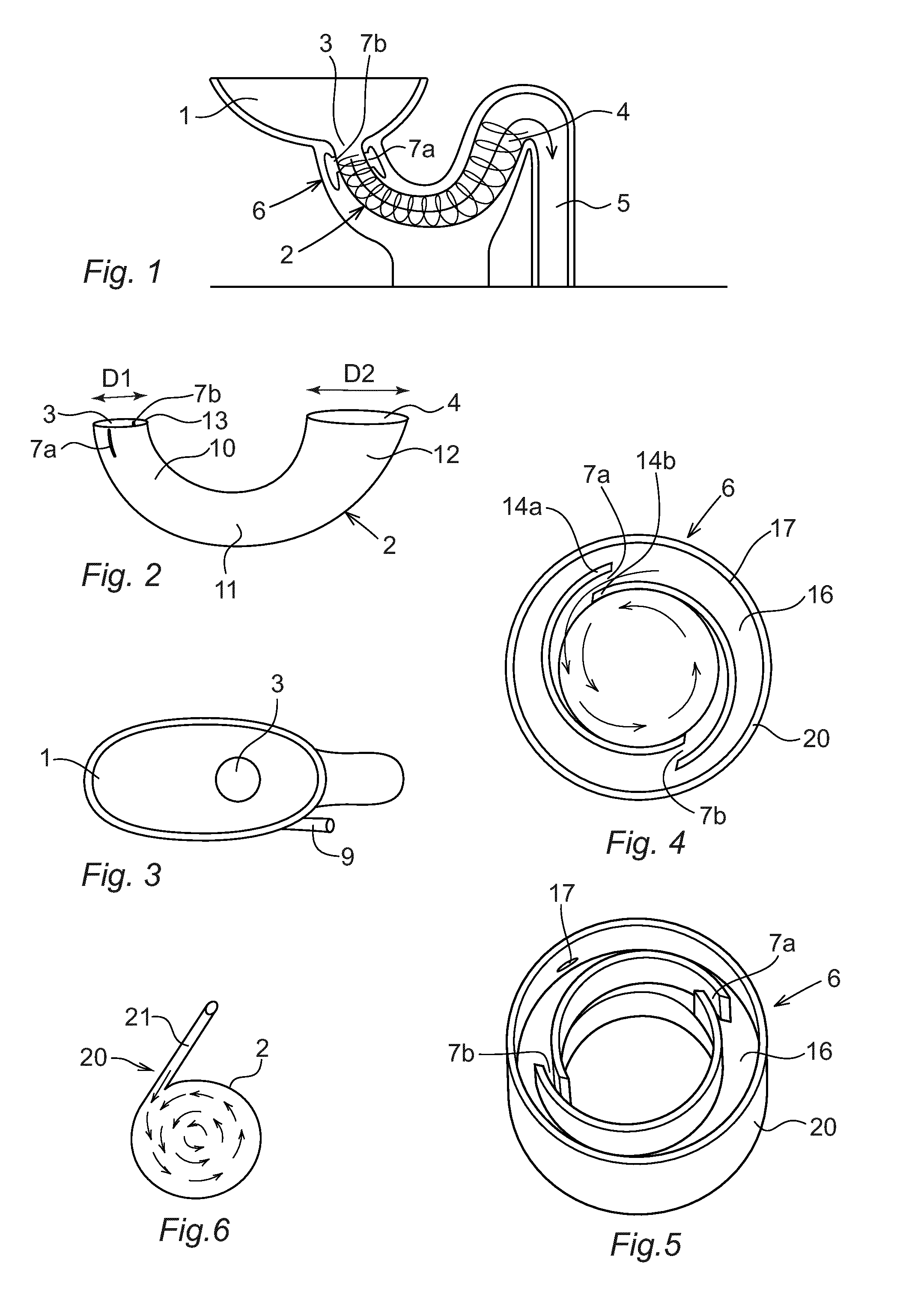

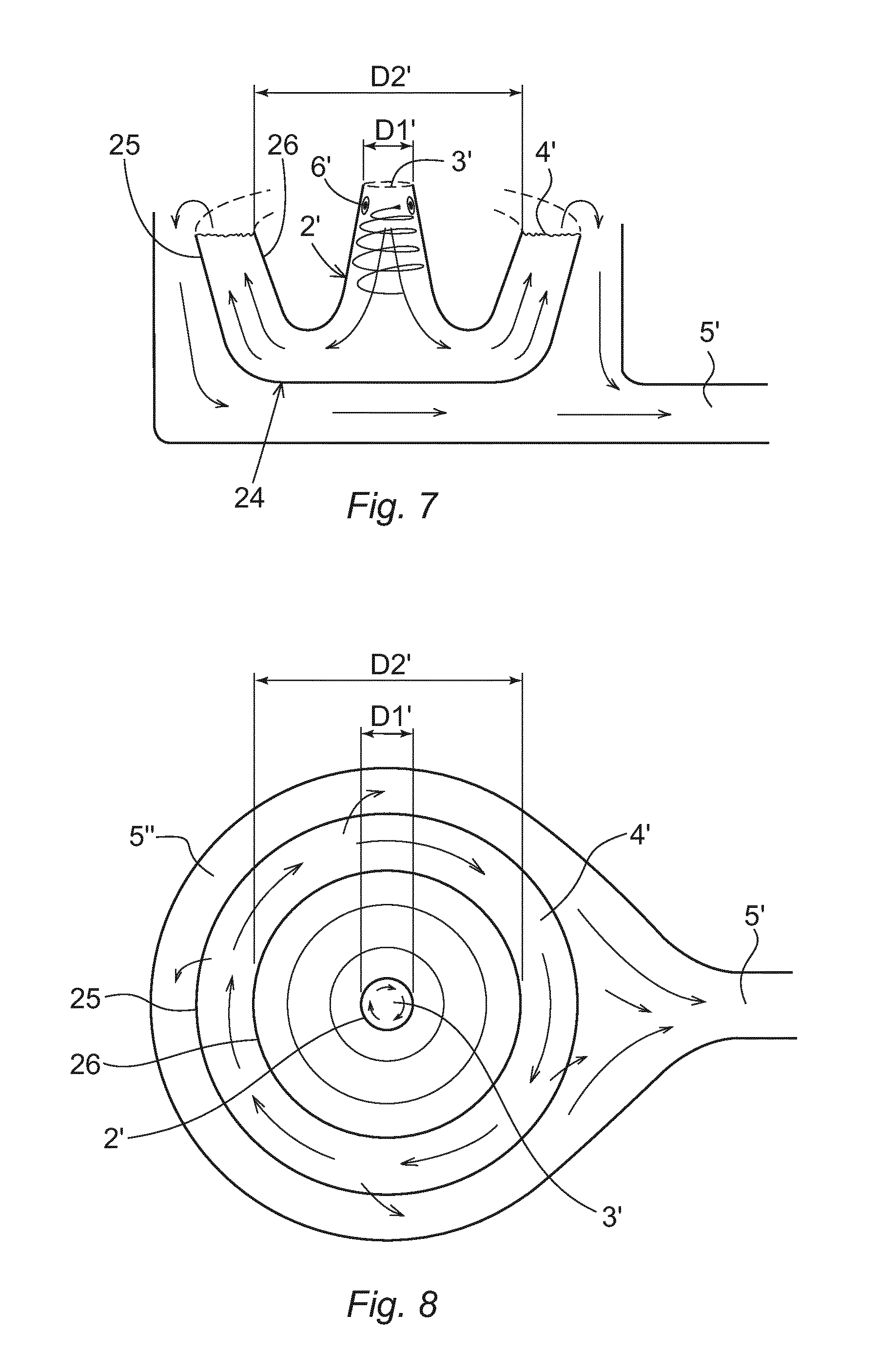

[0029]FIG. 1 shows a cross section cut through a toilet according to an embodiment of the invention. The toilet comprises a bowl 1, a water trap 2 in the form of a curved cone with an inlet 3 which is connected to the bowl, and an outlet 4 for connection to a sewer pipe 5, and a flushing system 6 arranged that upon activation, flush the water trap by generating a water vortex that travels towards the outlet. The sewer pipe 5 may be a part of toilet, or a separate part that is mounted in place. The flushing system 6 includes at least one nozzle. The embodiment shown in FIG. 1 has two nozzles 7a-b. The toilet bowl shape is preferably gently sloping towards the water trap inlet 3. The toilet is preferably made of porcelain, but may also be made of other materials such as metal sheet or plastic. In an alternative embodiment of the invention, all or at least part of the water trap inner wall is coated with a layer of hydrophobic material. Preferably greater portion of the inner wall is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com